A kind of preparation method of graphene airgel

A graphene airgel and graphene technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the unfavorable large-scale production of graphene airgel, potential safety hazards, unfavorable large-scale and large-scale Preparation of graphene airgel and other issues, to achieve the effect of mild process conditions, simple steps, good adsorption characteristics and piezoresistive properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

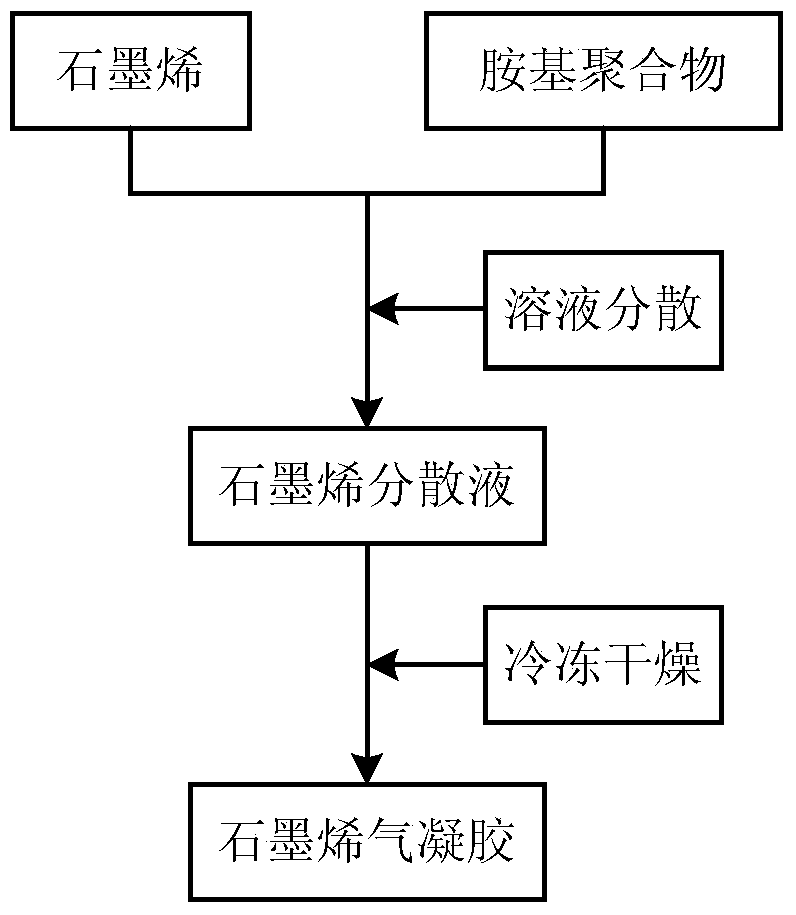

[0023] The invention provides a kind of preparation method of graphene airgel, comprises the following steps:

[0024] S1: adding graphene and amine-based polymers into the solvent and dispersing them to obtain a graphene dispersion;

[0025] S2: Freeze-drying the graphene dispersion to obtain graphene airgel.

[0026] Specifically, in the step S1, the graphene is selected from one or more of the oxidation-reduction method, the liquid phase exfoliation method, the arc method, the high temperature pyrolysis method and the chemical vapor deposition method. Graphene powder. The graphene includes single-layer or multi-layer graphene.

[0027] Oxidation-re-reduction method to prepare graphene is based on natural graphite as raw material, using oxidation reaction (introducing carboxyl and hydroxyl groups on carbon atoms on the edge of graphite layers, oxygen-containing groups such as epoxy and carbonyl groups between layers) to weaken the interaction between graphite layers. func...

Embodiment 1

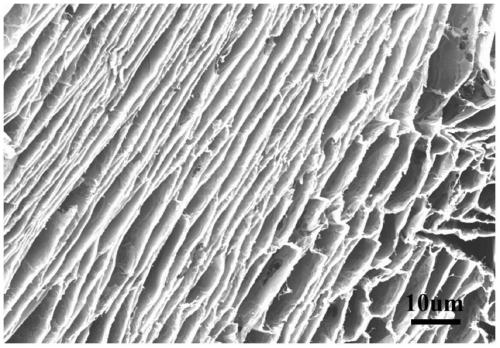

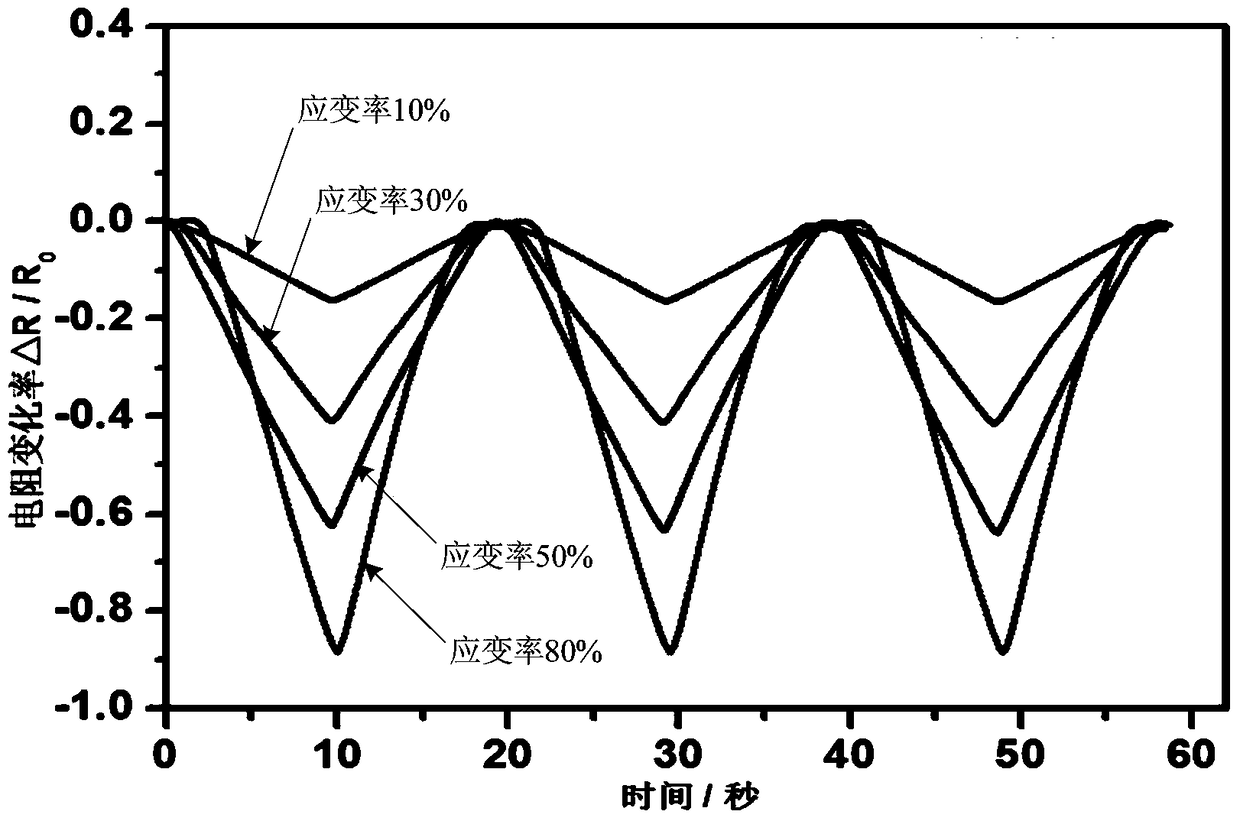

[0041] 100 mg of graphene powder obtained by the oxidation-re-reduction method and 25 mg of chitosan were added to 100 mL of deionized water, and the graphene powder was completely dispersed in water by ultrasound to form a stable dispersion. Take the above-mentioned dispersion liquid and put it into a container, and freeze-dry it at -30°C and 1.5Pa for 24 hours to obtain a graphene airgel block. figure 2 , 3 , 4 are the SEM picture of the obtained graphene airgel, the piezoresistive characteristic curve and the statistical chart of the adsorption capacity of different solvents, respectively. It can be seen that the graphene airgel obtained is a porous bulk material, has good pressure-sensitive properties, and has a large adsorption capacity (about 30-60 times its own weight) to water and some organic solvents. It is expected to be used as pressure sensitive sensor and water pollution treatment material.

Embodiment 2

[0043] 500 mg of graphene powder obtained by liquid phase exfoliation and 80 mg of polyaniline were added into 100 mL of deionized water, and the graphene powder was completely dispersed in water by ultrasonic waves to form a stable dispersion. Take the above-mentioned dispersion liquid and put it into a container, and freeze-dry it at -30°C and 1.5Pa for 36 hours to obtain a graphene airgel block.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com