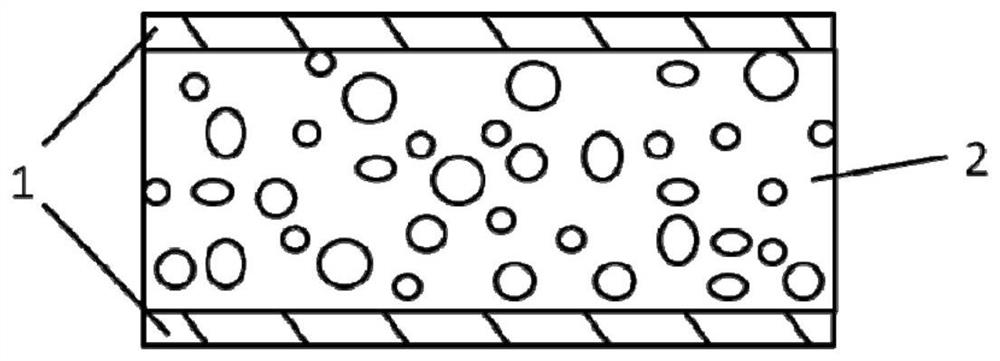

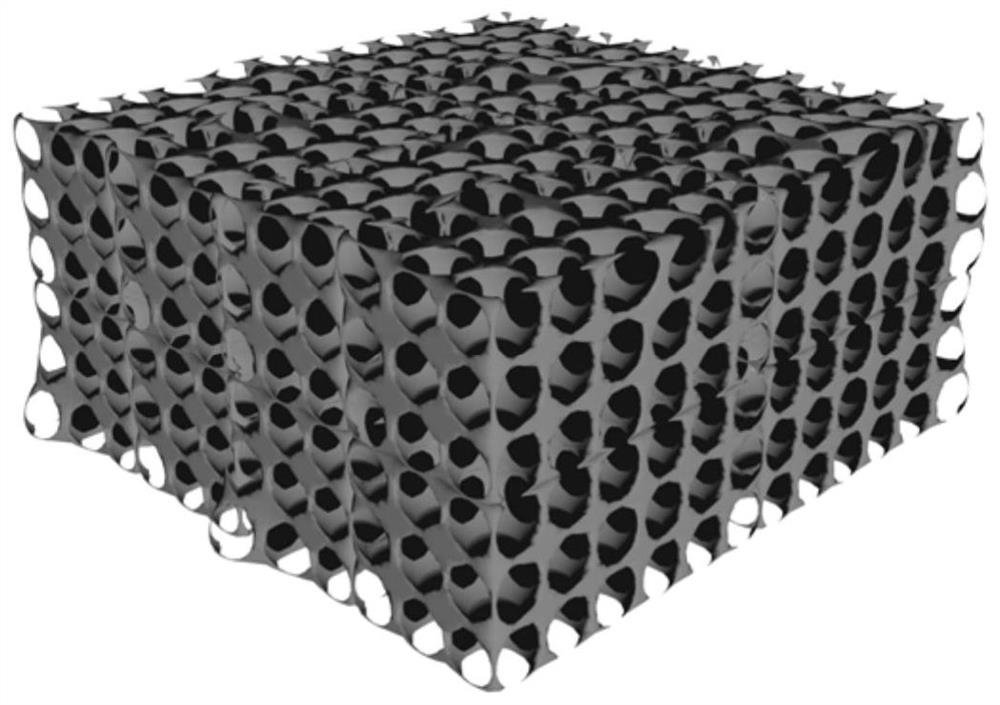

A piezoresistive sensor with superelastic porous structure and its preparation method

A piezoresistive sensor and porous structure technology, which is applied in the measurement of the property force of piezoresistive materials, etc., can solve the problems of inability to measure piezoresistive sensors, achieve good accuracy and piezoresistive sensitivity, high sensitivity, and reduce small damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Preparation of a piezoresistive sensor with a superelastic porous structure based on 3% acetylene black by mass.

[0028] Concrete preparation is carried out as follows:

[0029] 1. Mix the Eco-flex monomer and the curing agent according to the mass ratio of 1:1 to obtain the Eco-flex mixed solution, which is used to prepare the matrix material;

[0030] 2. Add acetylene black powder with a mass of 3% of the Eco-flex monomer used to the above mixed solution, and mix evenly to obtain a mixed solution;

[0031] 3. Add 6.67% CaCO in the above mixed solution 3 Powder and surfactant, fully mixed to obtain uncured conductive adhesive;

[0032] 4. Transfer the conductive adhesive to a clean glass template, and add CH with a volume concentration of 5% at a constant temperature of 20°C. 3 COOH, and stir to make it foam, then let it stand for a period of time, and then remove the excess CH 3 COOH poured out of the template;

[0033] 5. Heating the coated sample at...

Embodiment 2

[0035] Example 2: Preparation of a piezoresistive sensor with a superelastic porous structure based on 3.5% by mass of acetylene black.

[0036] Concrete preparation is carried out as follows:

[0037] 1. Mix the Eco-flex monomer and the curing agent according to the mass ratio of 1:1 to obtain the Eco-flex mixed solution, which is used to prepare the matrix material;

[0038]2. Add acetylene black powder with a mass of 3.5% of the Eco-flex monomer used to the above mixed solution, and mix evenly to obtain a mixed solution;

[0039] 3. Add 6.67% CaCO in the above mixed solution 3 Powder and surfactant, fully mixed to obtain uncured conductive adhesive;

[0040] 4. Transfer the conductive adhesive to a clean glass template, and add CH with a volume concentration of 5% at a constant temperature of 20°C. 3 COOH, and stirred to make the reaction foam. Then let it stand for a period of time to react, and then add excess CH 3 COOH poured out of the template;

[0041] 5. Heatin...

Embodiment 3

[0043] Example 3: Preparation of a piezoresistive sensor with a superelastic porous structure based on 5% acetylene black by mass.

[0044] Concrete preparation is carried out as follows:

[0045] 1. Mix the Eco-flex monomer and the curing agent according to the mass ratio of 1:1 to obtain the Eco-flex mixed solution, which is used to prepare the matrix material;

[0046] 2. Add acetylene black powder with a mass of 5% of the Eco-flex monomer used to the above mixed solution, and mix evenly to obtain a mixed solution;

[0047] 3. Add 6.67% CaCO in the above mixed solution 3 Powder and surfactant, fully mixed to obtain uncured conductive adhesive;

[0048] 4. Transfer the conductive adhesive to a clean glass template, and add CH with a volume concentration of 5% at a constant temperature of 20°C. 3 COOH, and stirred to make the reaction foam. Then let it stand for a period of time to react, and then add excess CH 3 COOH poured out of the template;

[0049] 5. Heating the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com