A sleeve-type elastic porous piezoresistive sensor for ureteral injury detection

A piezoresistive sensor, sleeve-type technology, applied in sensors, applications, gymnastics equipment, etc., can solve problems such as ureteral injury, urine leakage or hematuria, ureter accidental injury, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

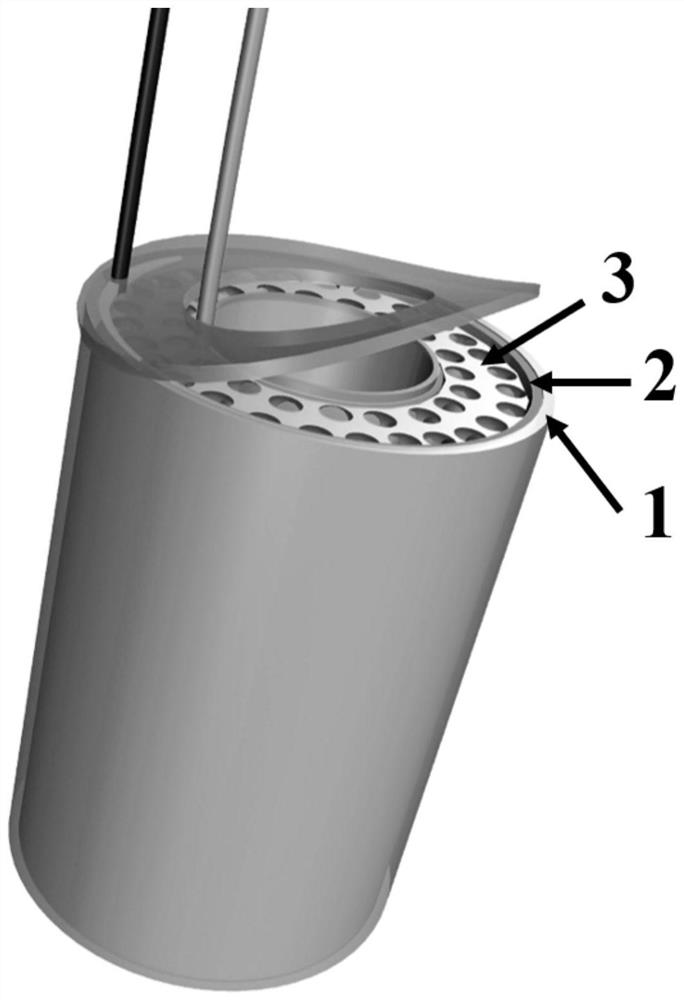

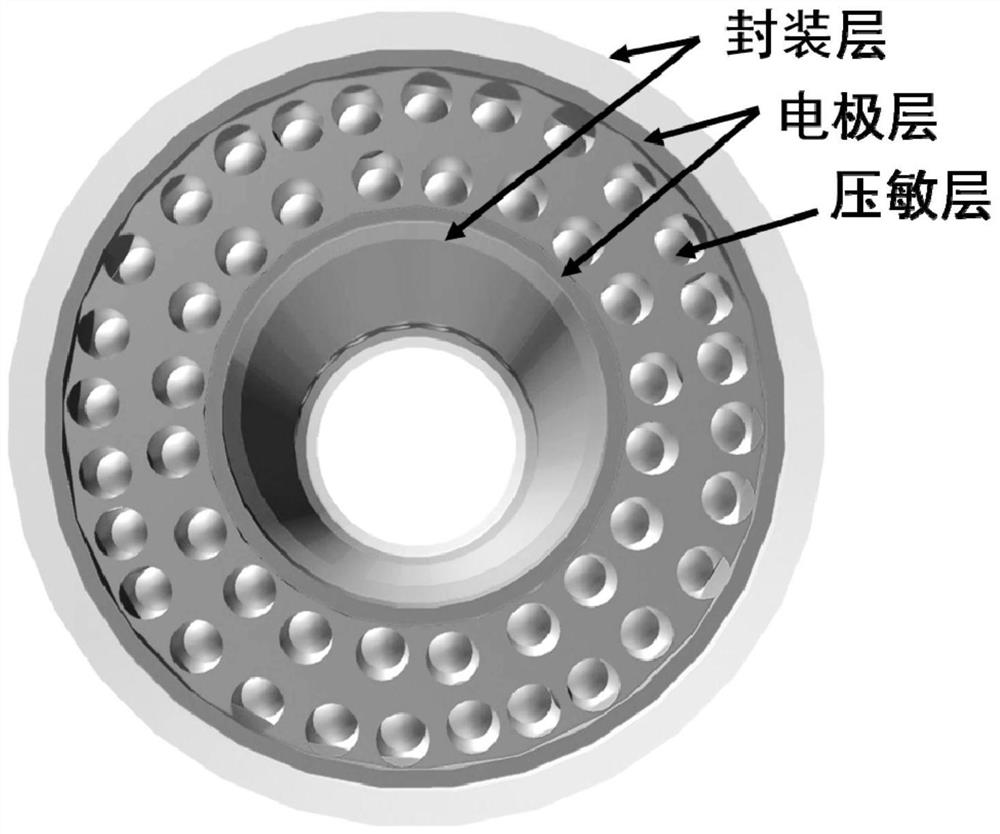

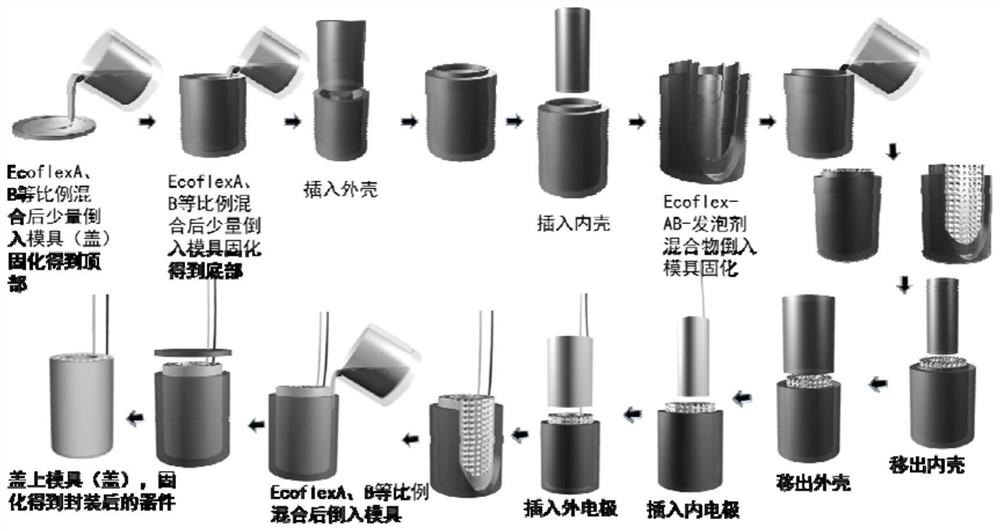

[0027] Example 1: Preparation of a sleeve-type elastic porous structure piezoresistive sensor with a sleeve thickness of 1 mm.

[0028] Concrete preparation is carried out as follows:

[0029] 1. Weigh a certain amount of acetylene black and blowing agent, and mix them evenly to form a solid mixture;

[0030] 2. Add the solid mixture to Ecoflex 00-30A and B with a mass ratio of 1:1, and add surfactant AEO-9, and mix thoroughly to obtain a mixture;

[0031] 3. Fill the obtained mixture into a clean mold to form a jelly. The inner and outer diameters of the mold are 3mm and 6mm respectively;

[0032] 4. Insulate the sample obtained in step 3 at 60°C for 2 hours to completely foam and solidify to obtain a pressure-sensitive layer with a porous structure;

[0033] 5. After removing the inner shell in the mold, paste flexible electrode layers on the inner and outer walls of the pressure-sensitive layer, fill in Ecoflex00-30 and cure and encapsulate at 60°C to make a sleeve-type p...

Embodiment 2

[0034] Example 2: Preparation of a sleeve-type elastic porous structure piezoresistive sensor with a sleeve thickness of 2 mm.

[0035] Concrete preparation is carried out as follows:

[0036] 1. Weigh a certain amount of acetylene black and blowing agent, and mix them evenly to form a solid mixture;

[0037] 2. Add the solid mixture to Ecoflex 00-30A and B with a mass ratio of 1:1, and add surfactant C8S, and mix thoroughly to obtain a mixture;

[0038] 3. Fill the obtained mixture into a clean mold to form a jelly. The inner and outer diameters of the mold are 3mm and 7mm respectively;

[0039] 4. Insulate the sample obtained in step 3 at 60°C for 2 hours to completely foam and solidify to obtain a pressure-sensitive layer with a porous structure;

[0040]5. After removing the inner shell in the mold, paste flexible electrode layers on the inner and outer walls of the pressure-sensitive layer, fill in Ecoflex00-30 and cure and encapsulate at 60°C to make a sleeve-type piez...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com