A kind of preparation method of hydrophilic three-dimensional graphene sponge

A graphene sponge and hydrophilic technology, applied in the field of wearable and artificial intelligence, can solve safety hazards, dangers and other problems, and achieve the effect of excellent piezoresistive characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

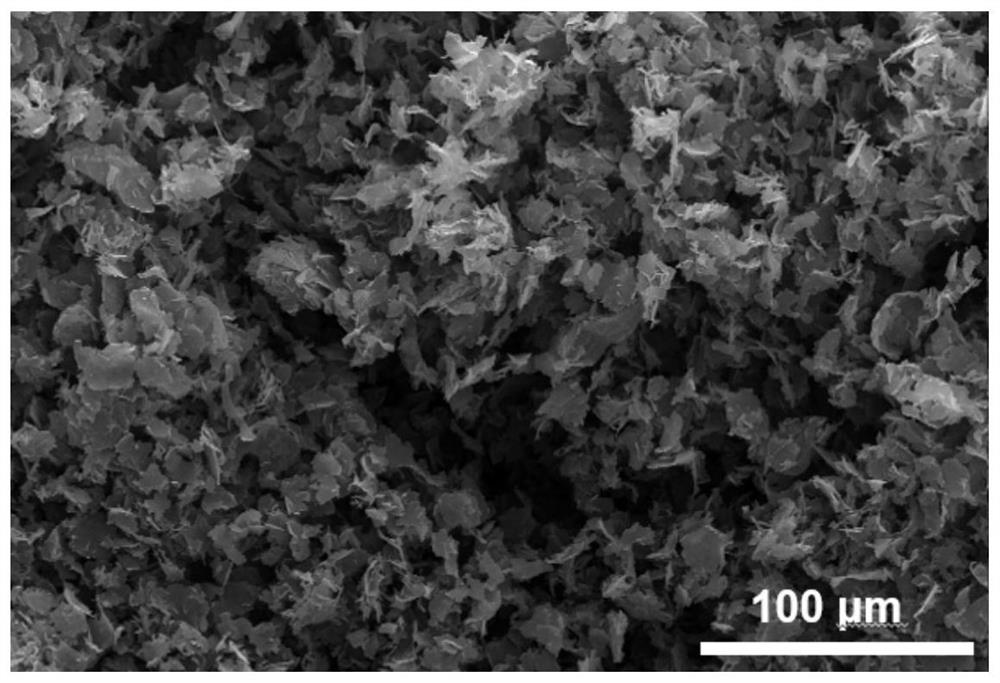

[0016] Take a 10 mg / ml water-soluble graphene dispersion with a rubber dropper and gradually drop it into liquid nitrogen (-196 °C). After the dispersion is condensed into ice, put it into a freeze dryer for vacuum drying. 24 hours to process. figure 1 Its scanning electron microscope picture can clearly observe the porous and loose structure. This porous structure endows it with ultra-low density and piezoresistive properties. figure 2 Optical images of 3D graphene sponges of different sizes and densities.

Embodiment 2

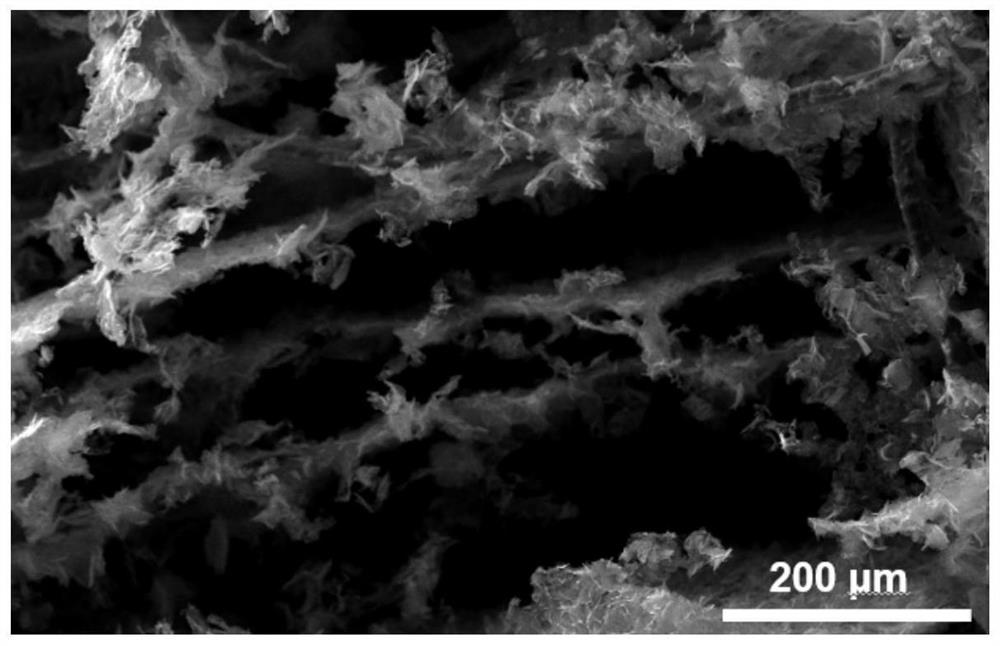

[0018] Take 10 mg / ml water-soluble graphene dispersion in a beaker, place it in a constant temperature cold trap (-20 ℃), and put it into a freeze dryer after the dispersion condenses into ice. Vacuum drying can be done for 48 hours. image 3 In its scanning electron microscope picture, an ordered porous and loose structure can be clearly observed. Figure 4 Optical image of the 3D graphene sponge.

Embodiment 3

[0020] The preparation method is the same as in Example 1, and the difference is: the concentration of the water-soluble graphene dispersion is 5 mg / ml, and the scanning electron microscope picture of the prepared three-dimensional graphene sponge is similar to figure 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com