Upwards-dialing and cutting type coal sample division device and division methods

A shrinking device and coal sample technology, which is applied in the field of coal sample shrinking, can solve the problems of small adaptable range of samples, limited weight range, water loss, etc., achieve small water loss and bias, reduce equipment volume, and simplify manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

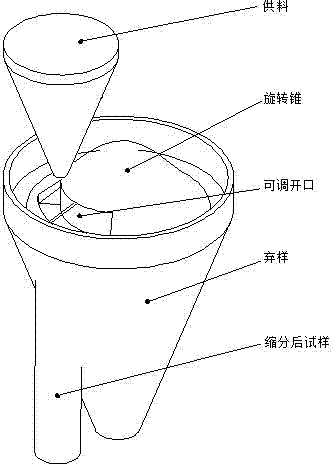

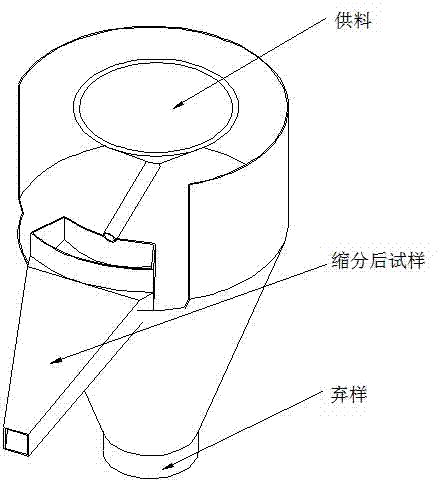

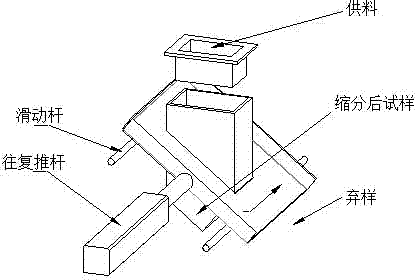

[0034] Through the study of the existing splitter, it is found that in order to obtain the reduced coal sample that meets the national standard, it is necessary to reduce the contact surface, contact time, and contact speed between the mechanical structure of the splitter and the sample as much as possible, and seek the reduction. The inside and outside of the device are really isolated (fully sealed). Therefore the present invention sets out from actual needs, has designed a kind of novel shrink divider, as Figure 7 As shown, the splitter includes a splitter body, and the splitter body includes an outer frame 2, a tapered shaper 10, a splitter dial 1 and a bifurcation baffle 9, wherein the top of the outer frame 2 has a test The sample inlet 4, the cone shaper 10 is installed at the sample inlet 4, the cone shaper 10 is a quadrangular truncated shape with a large top and a small bottom, that is, the top area of the cone shaper is greater than the bottom area, and its top s...

Embodiment 2

[0046] As an improvement of Embodiment 1, the vertebral body shaper 10 is detachably installed on the body of the shrinker body, the upper part of the vertebral body shaper is square, and the bottom is rectangular, so the bottom of the vertebral body shaper 10 has long sides and short sides. Side (the angle between the symmetrical long-side cone surface and the horizontal plane is greater than or equal to 60 degrees, and the length of the short side is greater than or equal to 3 times the maximum particle size of the coal sample passing through the cone). When the long side of the bottom of the vertebral body shaper 10 is parallel to the axial direction of the rotating mechanism, when the coal flow falls from the vertebral body shaper 10, the shrinking dial swings slightly. Slightly larger than the angle between the two side walls of the vertebral body shaper 10 (the two long sides at this time), to realize the segmental reduction of the coal flow. When the short side of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com