Optical element with lens barrel and manufacturing method thereof

A technology of optical components and manufacturing methods, which is applied in the directions of optical components, optics, installation, etc., can solve problems such as deterioration of the airtight seal of optical components, corrosion of stainless steel, and generation of rust, and achieve excellent airtight bonding and excellent airtight sealing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

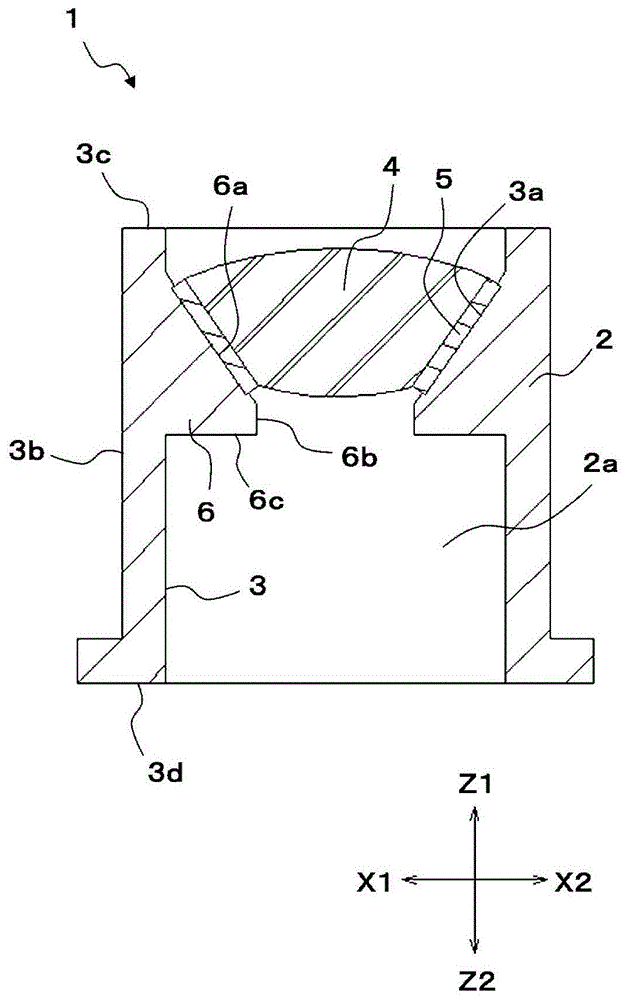

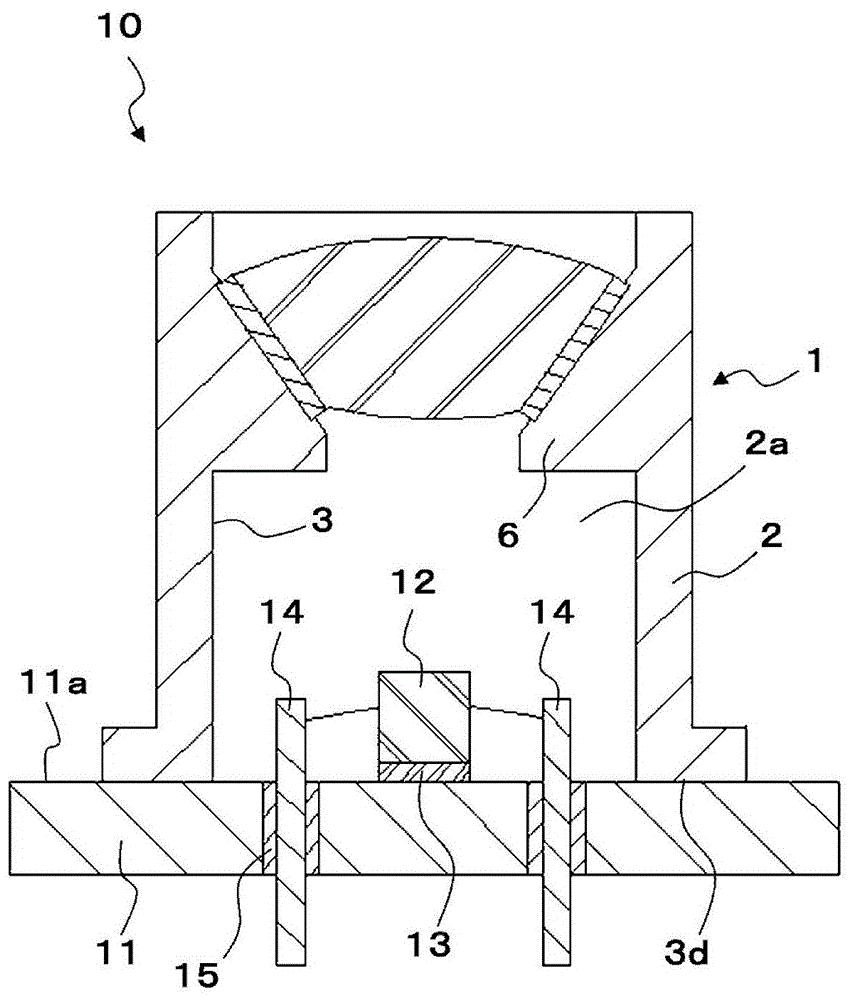

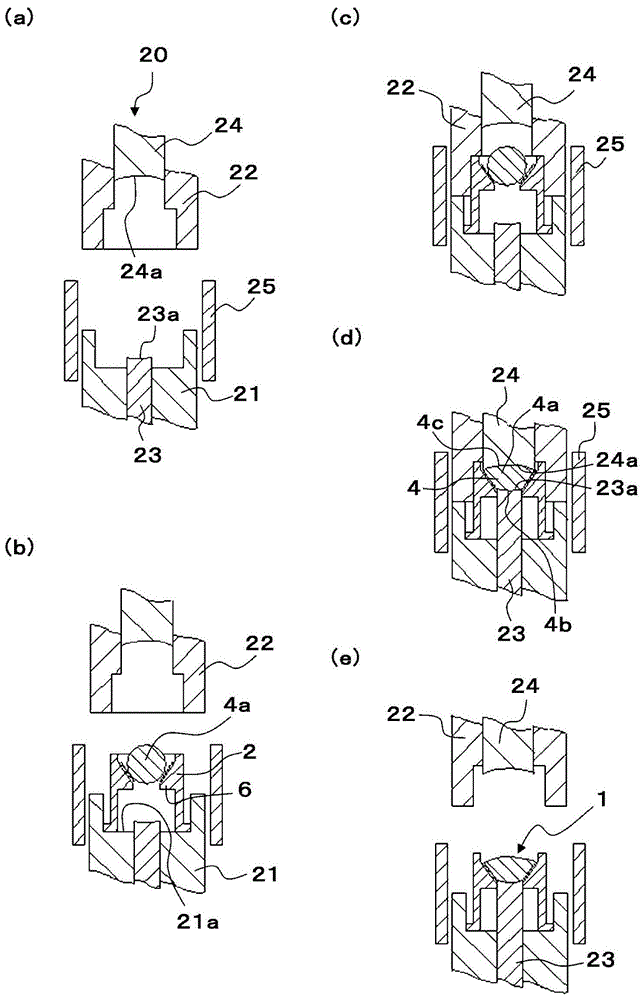

[0087] figure 1 It is a sectional view of the optical element with a lens barrel according to the first embodiment. figure 2 is a cross-sectional view of the optical module according to the first embodiment. image 3 It is explanatory drawing of the manufacturing method of the optical element with a lens barrel concerning 1st Embodiment. Figure 4 It is a partially enlarged cross-sectional view of the optical element with lens barrel according to the first embodiment.

[0088] Such as figure 1 As shown, the optical element 1 with a lens barrel according to the present embodiment is configured to include a lens barrel 2 and a lens 4 as an optical element. The lens barrel 2 is circular in plan view, formed in a cylindrical shape having a through hole 2 a , and has a protrusion 6 protruding inward from the inner peripheral surface 3 of the lens barrel 2 . The protrusion 6 has a surface continuously provided in the order of the protrusion slope 6a, the protrusion side surfa...

no. 2 approach >

[0128] Figure 6 It is a cross-sectional view of the optical element with lens barrel according to the second embodiment. In the optical element with lens barrel 31 according to the second embodiment, as Figure 6 As shown, the metal oxide layer 5 is laminated on the entire surface of the inner peripheral surface 3 of the lens barrel 2 . Furthermore, the metal oxide layer 5 is sequentially stacked with a first metal oxide layer made of chromium (Cr) oxide and a second metal oxide layer made of iron (Fe) oxide.

[0129] The optical element with a lens barrel 31 according to the present embodiment is different from the optical element with a lens barrel 1 according to the first embodiment in that, compared to the optical element with a lens barrel 1 , only the figure 1 The second metal oxide layer is formed in the region of the barrel joint surface 3 a shown in FIG. Regarding other points, the two optical elements with lens barrels 1 and 31 have substantially the same configur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com