Touch screen panel, touch display panel and display device

A touch display panel, touch screen technology, applied in instruments, computing, electrical and digital data processing, etc., can solve the problems of high production cost, low light transmittance, and thick module of the external touch screen, so as to reduce the impact and improve the information. Noise ratio, the effect of removing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

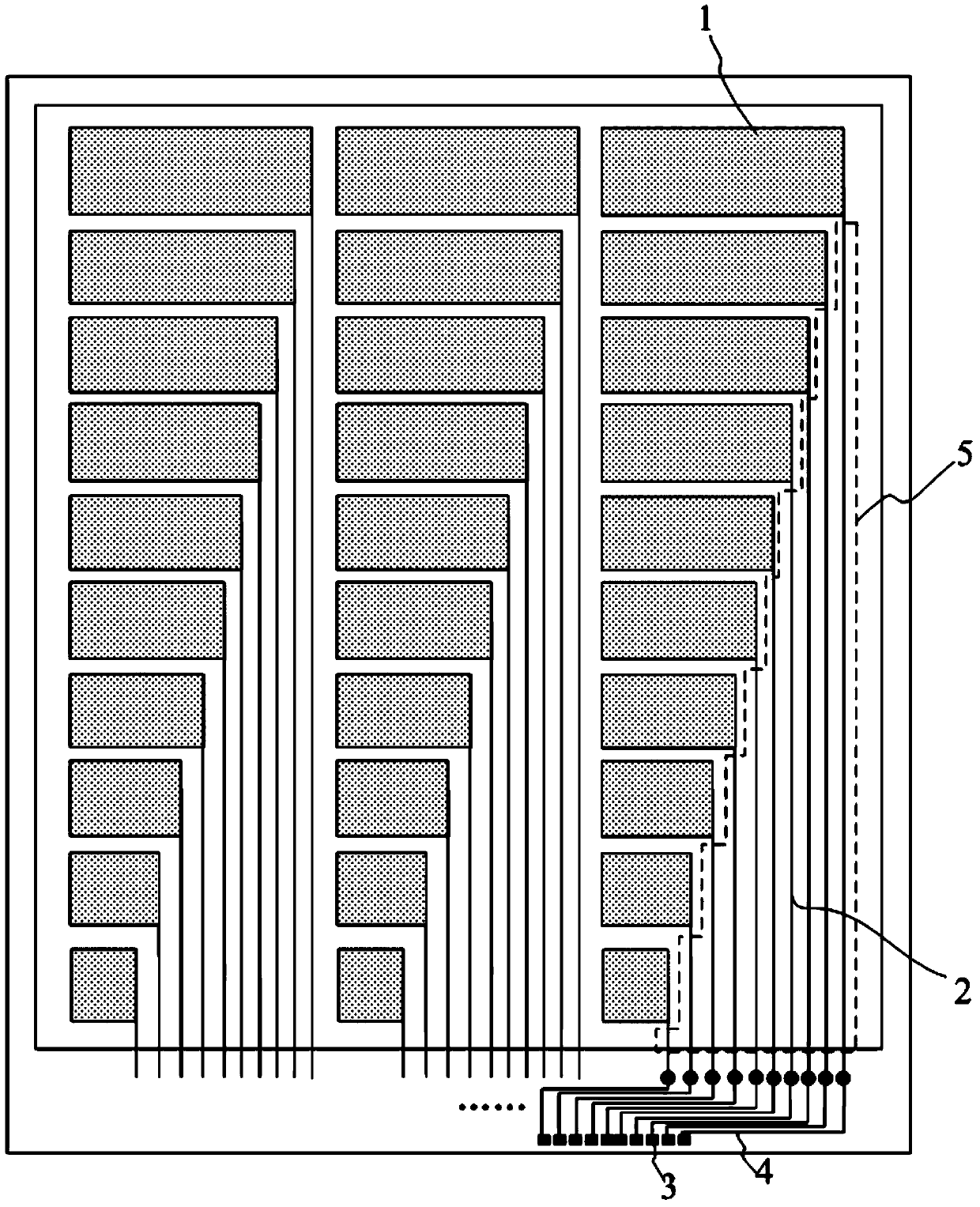

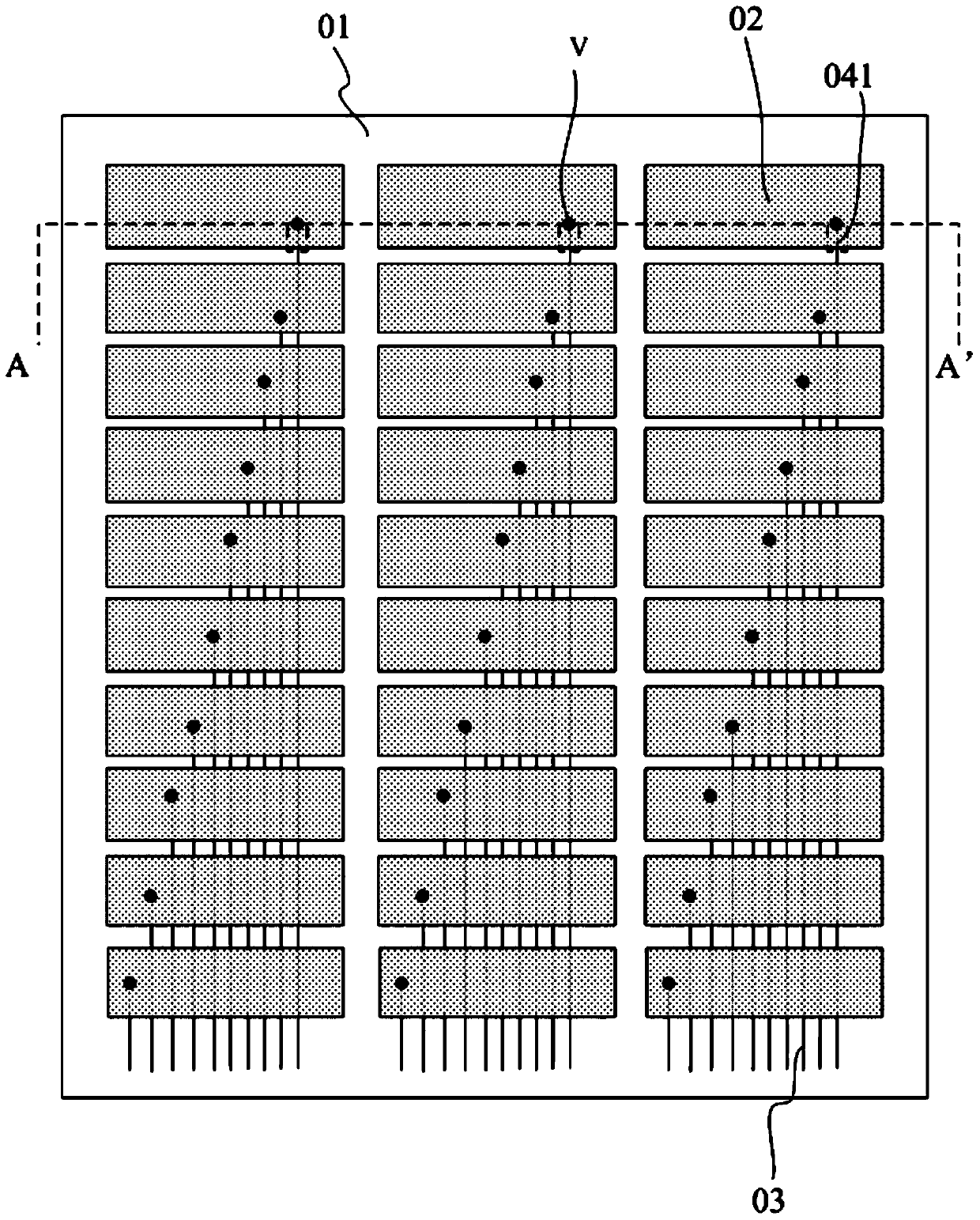

[0073] Such as Figure 5a As shown, the touch display panel includes a first substrate 100 and a second substrate 200, wherein the first substrate is the first substrate of the above-mentioned touch screen, and the inner side of the first substrate 100 is sequentially provided with a gate layer 101, an active layer 102, and a source-drain layer. The electrode layer 103, the first passivation layer 104, the wire 105, the insulating layer 106, the common electrode layer 107, the second passivation layer 108, and the pixel electrode layer 109, wherein the common electrode layer 107 is multiplexed as a touch electrode, and at the same time The common electrode layer 107 is also provided with a first electromagnetic shielding layer 1071 (such as Figure 5a The region shown in the dotted line box), and the common electrode layer 107 multiplexed as the touch electrode is electrically connected to the corresponding wire 105 through the via hole V penetrating the insulating layer 106 ....

example 2

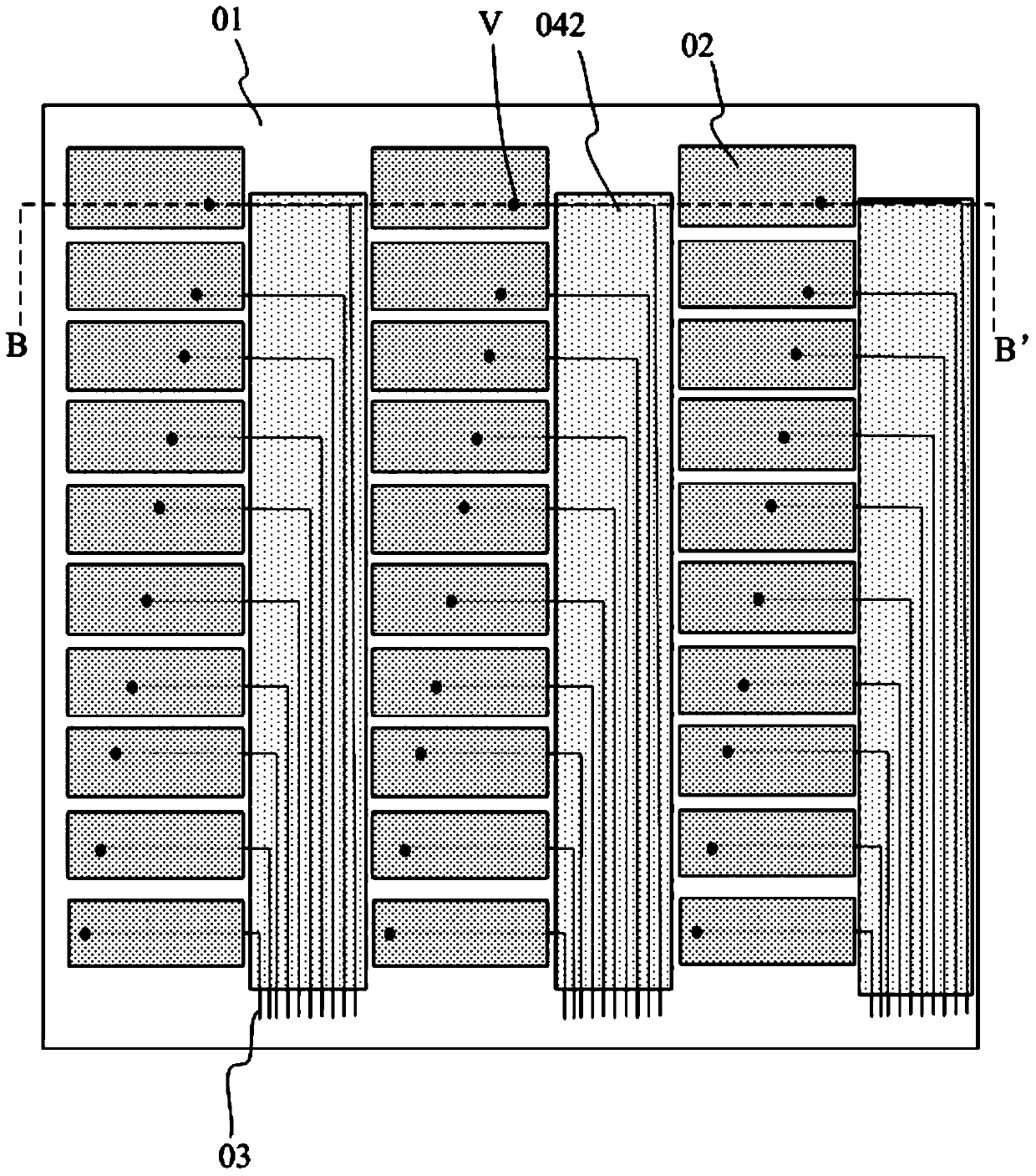

[0075] Such as Figure 5b As shown, the touch display panel includes a first substrate 100 and a second substrate 200, wherein the first substrate is the substrate of the above-mentioned touch screen, and the inner side of the first substrate 100 is sequentially provided with a gate layer 101, an active layer 102, and a source-drain electrode layer. 103, the first passivation layer 104, the first insulating layer 1061, the common electrode layer 107 and the wire 105 arranged in the same layer, the second insulating layer 1062, the second electromagnetic shielding layer 110, the second passivation layer 108, and the pixel electrode Layer 109, wherein the second electromagnetic shielding layer 110 is grounded, the common electrode layer 107 is multiplexed as a touch electrode, the wires are located between the touch electrodes, and the orthographic projection of the wires 105 on the first substrate 100 is located on the second electromagnetic shielding layer 110 In the region wh...

example 3

[0077] Such as Figure 5c As shown, the touch display panel includes a first substrate 100 and a second substrate 200, wherein the first substrate is the substrate of the above-mentioned touch screen, and the inner side of the first substrate 100 is sequentially provided with a gate layer 101, an active layer 102, and a source-drain electrode layer. 103, the first passivation layer 104, the wire 105, the insulating layer 106, the common electrode layer 107, the second electromagnetic shielding layer 110, the second passivation layer 108, and the pixel electrode layer 109 arranged in the same layer, wherein, the common electrode layer The second electromagnetic shielding layer 110 provided on the same layer as the layer 107 is located between the common electrodes and is grounded. The common electrode layer 107 is multiplexed as a touch electrode, and the common electrode layer 107 multiplexed as a touch electrode passes through the insulating layer 106. The holes V are electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com