Safety insulation ladder for operation and maintenance management of substations

An operation and maintenance management and insulation ladder technology, which is applied to ladders, electrical components, switch devices, etc., can solve the problems of difficult loading and unloading, difficult to take off, and can not guarantee the life safety of electric workers, so as to avoid the phenomenon of easy damage, Good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

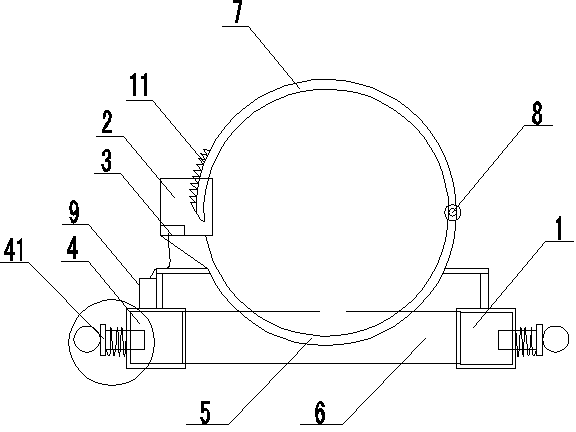

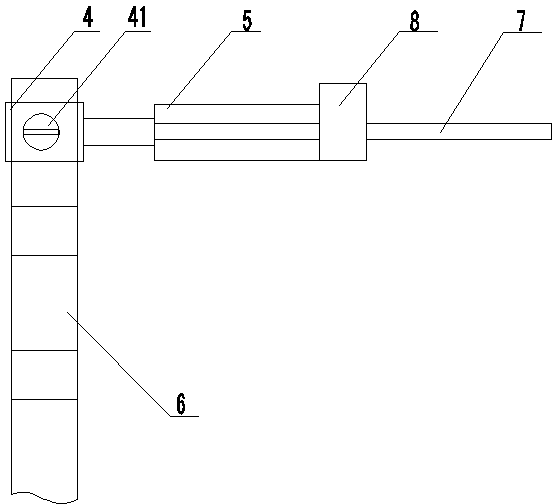

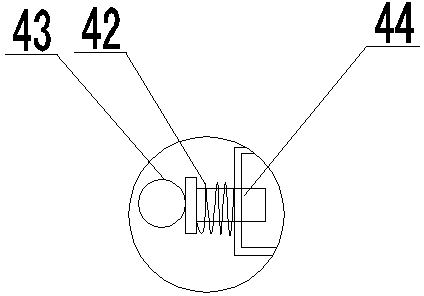

[0019] Embodiment 1: A safety insulating ladder for substation operation and maintenance management, including an insulating ladder body 6, a locking mechanism is arranged on the upper part of the insulating ladder body 6, and the locking mechanism includes a left hoop 4, a right hoop 1 and a lock Tightening module, the left hoop 4 is connected with the right hoop 1 through the locking module, and the locking module includes a C-shaped support rod 5, a drive motor 8, a C-shaped locking rod 7, an electronic lock 2 and a processor 3. One end of the C-shaped support rod 5 is connected to the C-shaped locking rod 7 through a drive motor 8, the other end of the C-shaped support rod 5 is provided with an electronic lock 2, and the end of the C-shaped locking rod 7 is provided with an electronic lock. The locking tooth 11 matched with the lock 2, the drive motor 8 and the electronic lock 2 are connected to the processor 3 through wires.

[0020] The C-shaped support rod 5 is a hollow...

Embodiment 2

[0024] Embodiment 2: A safety insulating ladder for substation operation and maintenance management, including an insulating ladder body 6, a locking mechanism is arranged on the upper part of the insulating ladder body 6, and the locking mechanism includes a left hoop 4, a right hoop 1 and a lock Tightening module, the left hoop 4 is connected with the right hoop 1 through the locking module, and the locking module includes a C-shaped support rod 5, a drive motor 8, a C-shaped locking rod 7, an electronic lock 2 and a processor 3. One end of the C-shaped support rod 5 is connected to the C-shaped locking rod 7 through a drive motor 8, the other end of the C-shaped support rod 5 is provided with an electronic lock 2, and the end of the C-shaped locking rod 7 is provided with an electronic lock. The locking tooth 11 matched with the lock 2, the drive motor 8 and the electronic lock 2 are connected to the processor 3 through wires.

[0025] The C-shaped support rod 5 is a hollow...

Embodiment 3

[0028] Embodiment 3: A safety insulating ladder for substation operation and maintenance management, including an insulating ladder body 6, a locking mechanism is arranged on the upper part of the insulating ladder body 6, and the locking mechanism includes a left hoop 4, a right hoop 1 and a lock Tightening module, the left hoop 4 is connected with the right hoop 1 through the locking module, and the locking module includes a C-shaped support rod 5, a drive motor 8, a C-shaped locking rod 7, an electronic lock 2 and a processor 3. One end of the C-shaped support rod 5 is connected to the C-shaped locking rod 7 through a drive motor 8, the other end of the C-shaped support rod 5 is provided with an electronic lock 2, and the end of the C-shaped locking rod 7 is provided with an electronic lock. The locking tooth 11 matched with the lock 2, the drive motor 8 and the electronic lock 2 are connected to the processor 3 through wires.

[0029] In the present invention, a round hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com