Double-faced toy vehicle

A toy car, double-sided technology, applied in the field of toy cars, can solve problems such as power consumption, motor energy loss, and shortened lifespan, and achieve the effects of simple design, space saving, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

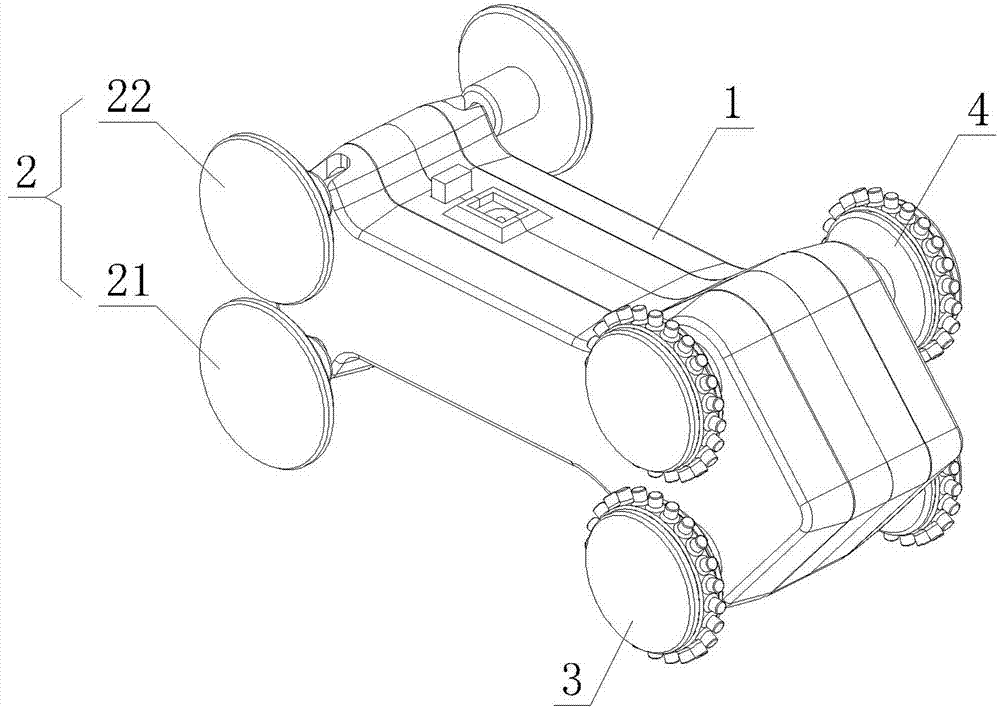

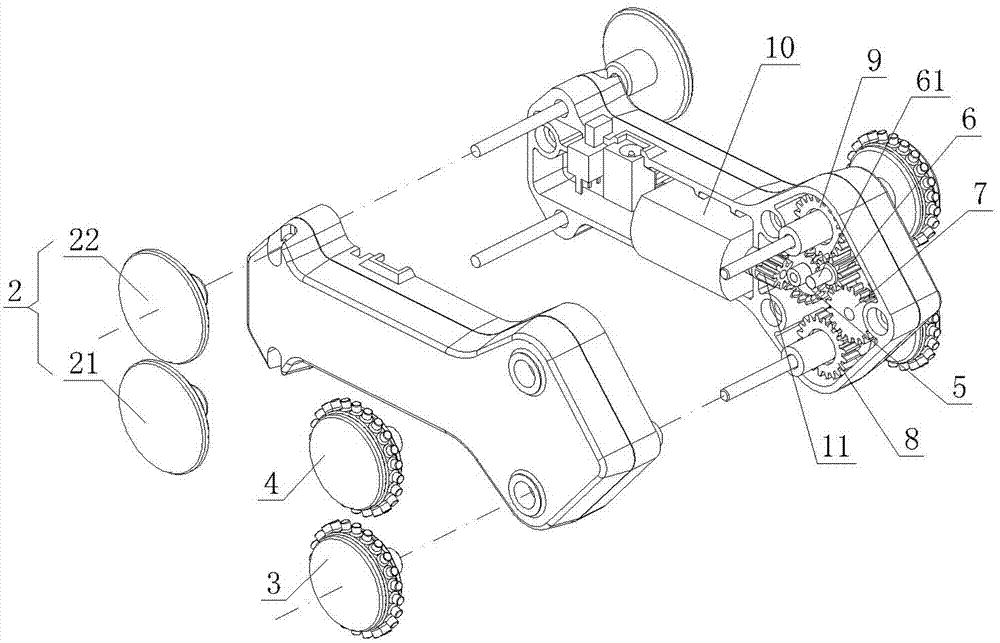

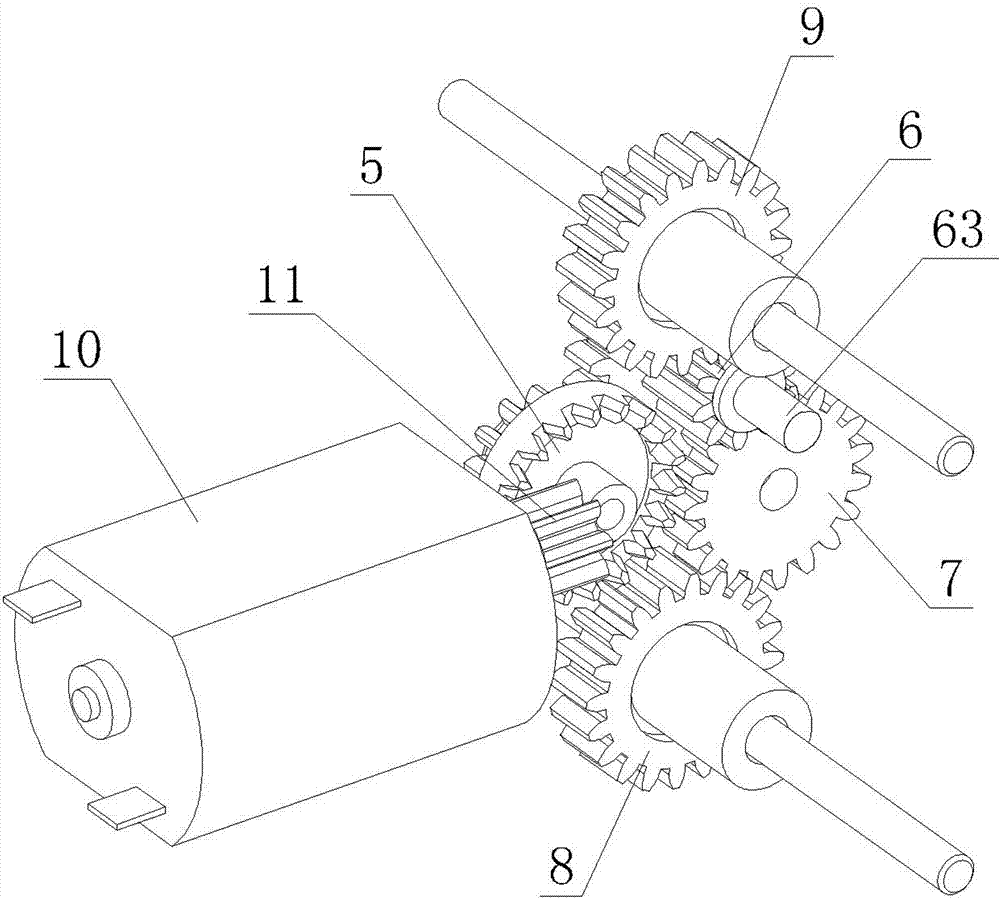

[0023] Such as Figure 1 to Figure 4As shown, the transmission mechanism of this embodiment includes a reversing gear 5, a dual gear 6, a transition gear 7, a first output gear 8 and a second output gear 9, the reversing gear 5 is a crown gear, and the shaft gear 11 corresponds to the spur gear designed to mesh with the crown teeth 52 of the crown gear, and the axial gear 51 is arranged on the back of the crown gear and is coaxial with the crown gear, the large gear of the double gear 6 (that is, the first gear 61) Engaged with the axial gear 51, the upper end of the pinion (i.e. the second gear 62) of the dual gear 6 is engaged with the second output gear 9, which is arranged on the axle of the second drive wheel 4 , the second driving wheel 4 is two driving wheels that are arranged on the rear upper part of the car body 1 and protrude to the upper part of the car body 1; And transition gear 7 is meshed with first output gear 8 again, and this first output gear 8 is arranged...

Embodiment 2

[0025] Such as Figure 5 As shown, the transmission mechanism of this embodiment includes a reversing gear 5, a duplex gear 6, three transition gears 7, a first output gear 8 and a second output gear 9, the reversing gear 5 is a crown gear, and the rotating shaft The gear 11 corresponds to a spur gear designed to mesh with the crown teeth 52 of the crown gear, and the axial gear 51 is arranged on the back side of the crown gear and is coaxial with the crown gear. ) meshes with the axial gear 51, and the upper end of the pinion of the dual gear 6 (that is, the second gear 62) meshes with the second output gear 9, which is arranged on the axle of the second drive wheel 4 Above, the second driving wheel 4 is two driving wheels arranged on the rear upper part of the car body 1 and protruding to the upper part of the car body 1; The transition gear 7 meshes with the second transition gear 7, the second transition gear 7 meshes with the third transition gear 7, and finally the thir...

Embodiment 3

[0027] Such as Figure 6 As shown, the transmission mechanism of this embodiment includes a reversing gear 5, a first dual gear 6A and a second dual gear 6B, a transition gear 7, and a first output gear 8 and a second output gear 9. The gear 5 is a crown gear, and the rotating shaft gear 11 corresponds to a spur gear designed to mesh with the crown teeth 52 of the crown gear. The axial gear 51 is arranged on the back of the crown gear and coaxial with the crown gear. The first double gear 6A The large gear (that is, the first gear 6A1) meshes with the lower end of the axial gear 51, and the pinion (that is, the second gear 6A2) of the first dual gear 6A meshes with the first output gear 8, and the first output Gear 8 is arranged on the axle of first driving wheel 3, and first driving wheel 3 is arranged on the rear lower part of car body 1 and two driving wheels protruding to the lower part of car body 1; The first gear 6B1) is meshed with the upper end of the axial gear 51, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com