pressure vessel

A technology for pressure vessels and containers, applied in the field of pressure vessels, can solve problems such as limited service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

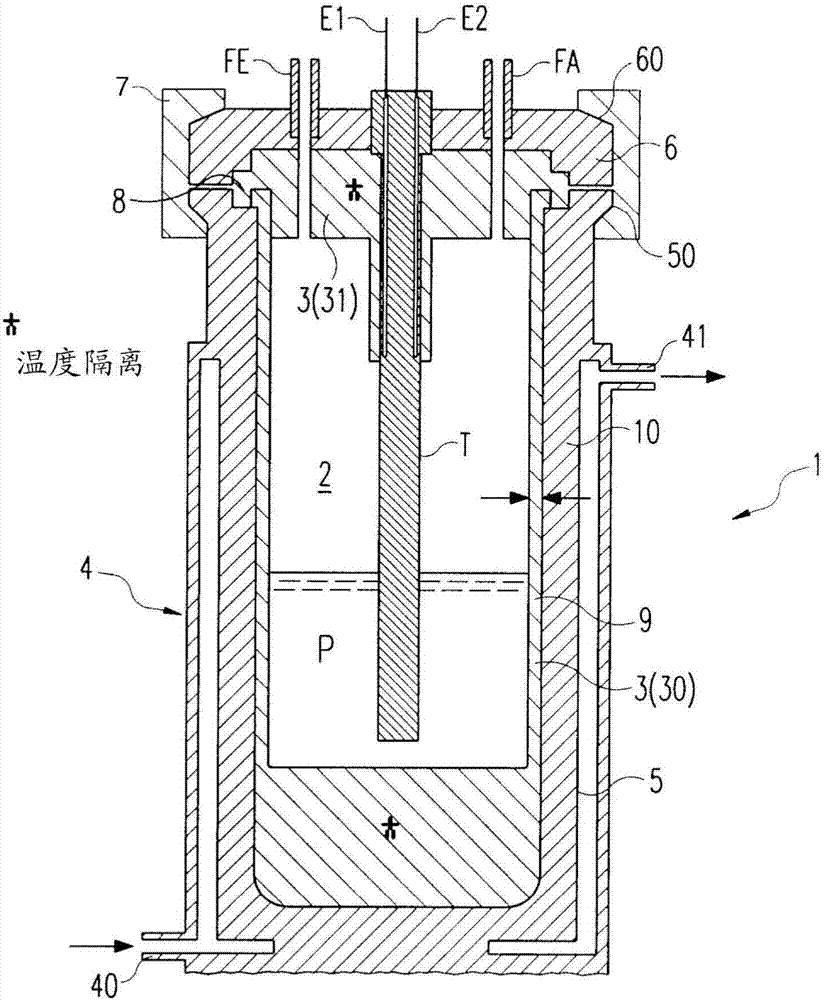

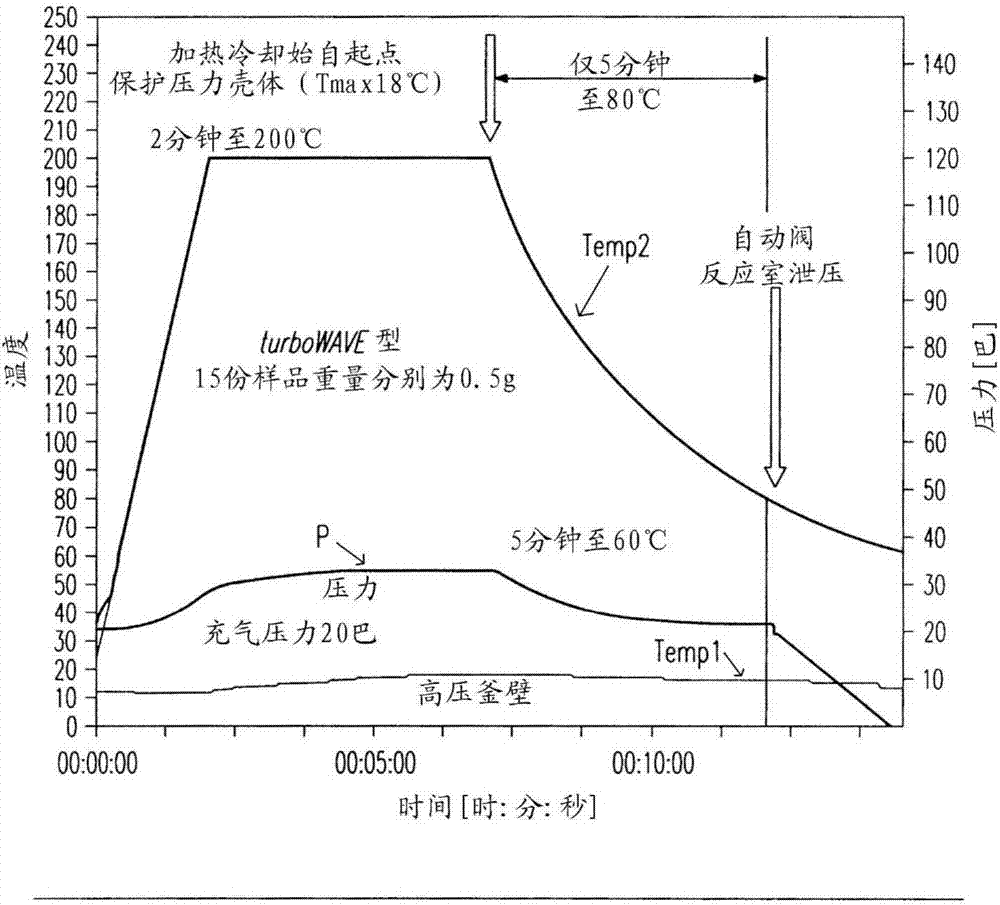

[0052] figure 1 and figure 2 A first and a second embodiment of a pressure vessel 1 (hereinafter also referred to as vessel or sample vessel) according to the invention are shown for containing a sample P to be heated in order to initiate and / or facilitate a chemical pressure reaction on the sample P and / or physical stress response. The pressure vessel 1 consists of a high-pressure resistant material, for example a metal, preferably steel, particularly preferably a special metal alloy. The pressure vessel 1 is here preferably designed such that it can be used at pressures of up to at least 200 bar, preferably up to at least 500 bar, and at temperatures above 300° C.

[0053]The pressure vessel 1 surrounds the reaction chamber 2 . The sample P is arranged in the reaction chamber 2 for sample processing and can be withdrawn therefrom preferably through the opening.

[0054] Furthermore, the pressure vessel 1 has an insulating lining 3 (the so-called liner) surrounding the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com