3D (three-dimensional) metal printing method

A metal and 3D technology, applied in the direction of improving process efficiency and energy efficiency, can solve problems such as incomplete sintering, powder collapse and pollution, and achieve the effect of ensuring utilization efficiency, simple system equipment, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

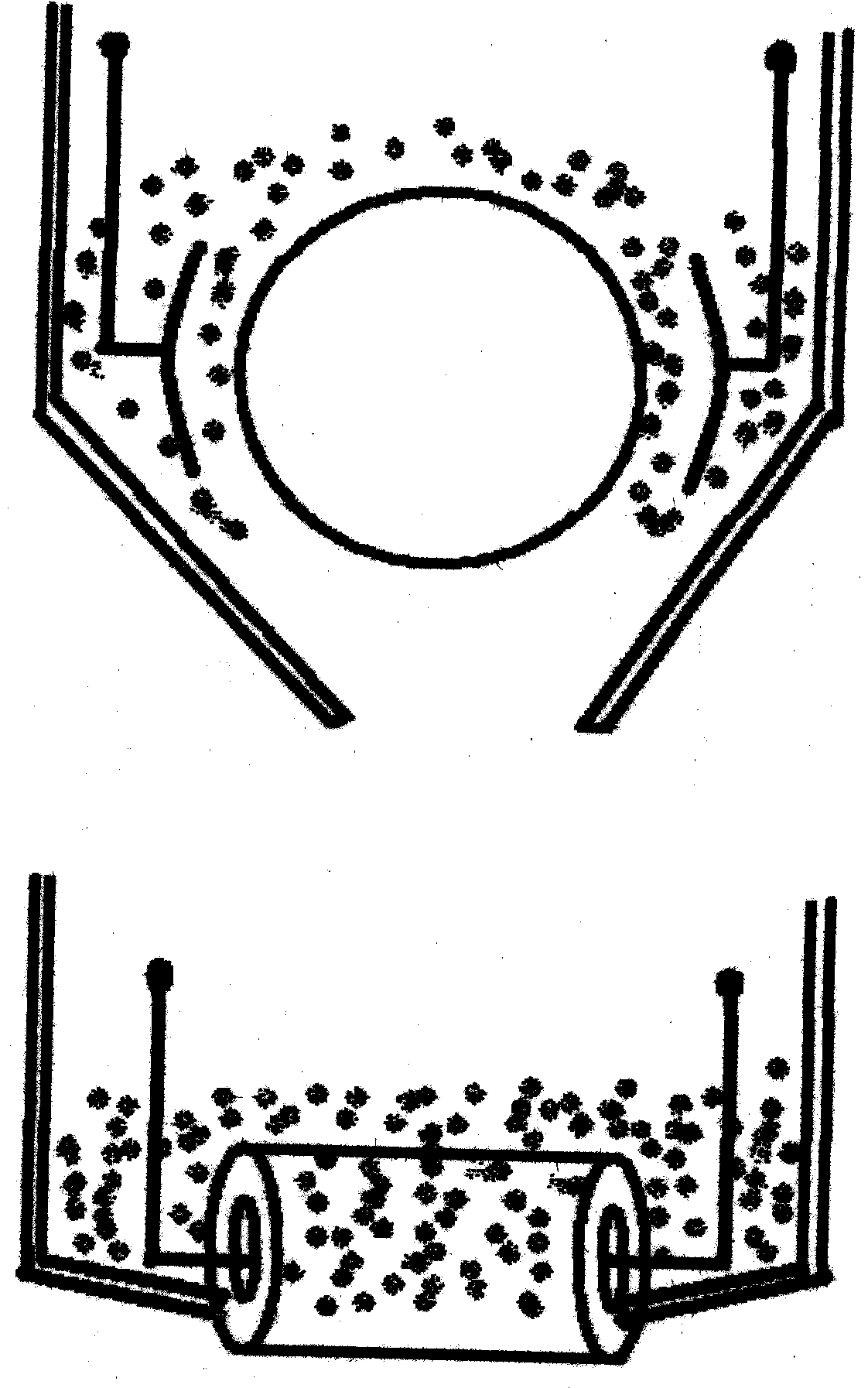

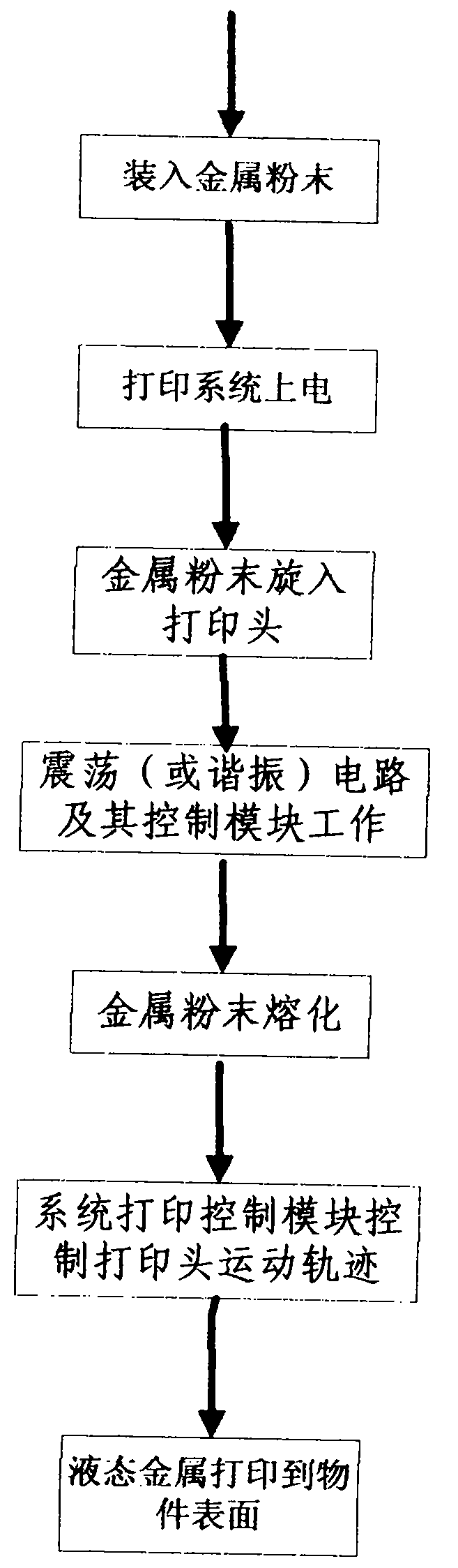

[0021] In order to solve the problem of how to realize the printing of metal powder like ink, and the existing laser sintering molding may not be complete, the metal powder in the electron beam melting technology is easy to collapse and the equipment is complicated. Such as figure 1 and figure 2 As shown, the present invention provides a kind of 3D metal printing method, and described method is based on the printing method (or adopting other methods that utilize oscillation (or resonance) electric energy) similar to the ink flowing out of a ballpoint pen, and the rolling bearing rolling on the surface, combined with current or The voltage oscillating (or resonant) circuit realizes the rapid melting and fine printing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com