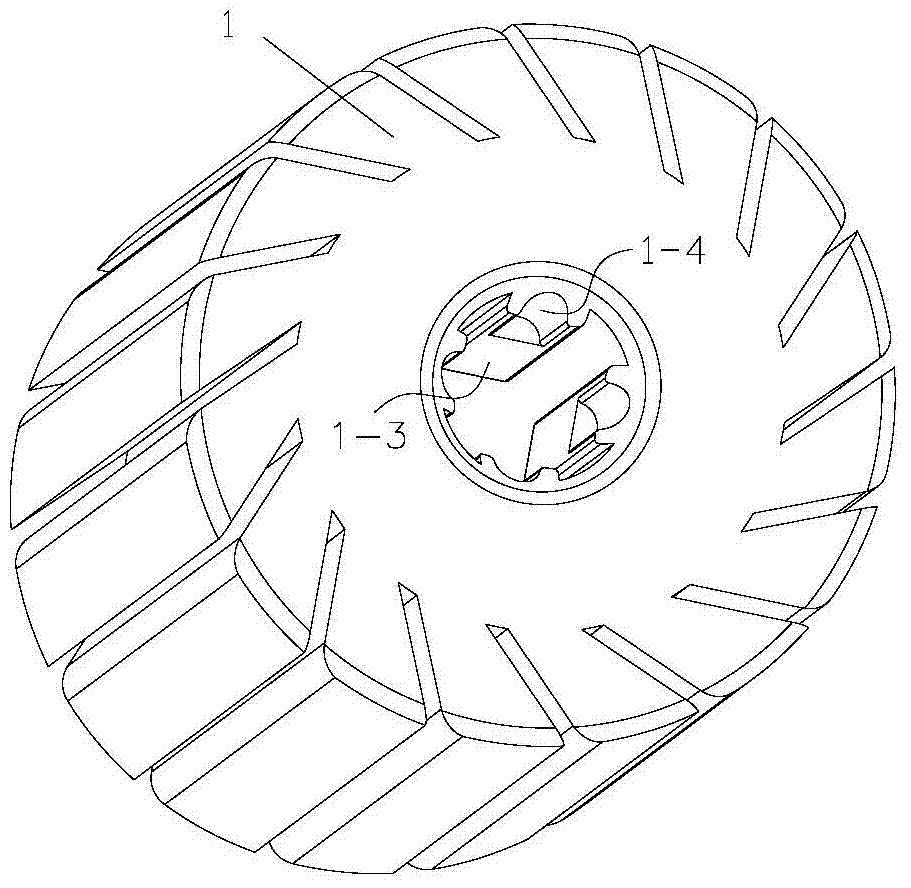

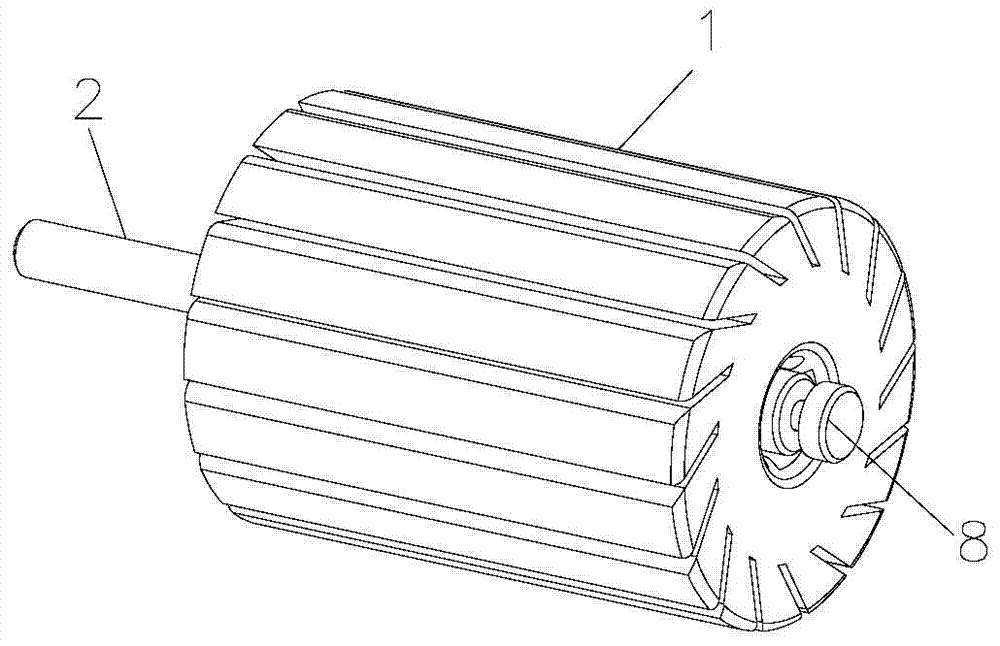

Polisher, polishing head quick-detaching mechanism and using method thereof

A technology of grinding heads and grinders, which is applied to the parts of grinding machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve the problems such as difficult replacement of grinding heads, and achieve the advantages of small man-hour consumption, fast installation and disassembly, and easy operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] In this embodiment, the elastic member adopts the shrapnel 4, such as Figure 4 Figure 8 As shown, the shrapnel 4 includes a rear section 4-1, an arched section 4-2 and a front section 4-3, and the rear section 4-1, the arched section 4-2 and the front section 4-3 are sequentially connected to form the main part of the shrapnel 4, The connection point of rear section 4-1 and arch section 4-2 forms a horizontal connection with the connection point of front section 4-3 and arch section 4-2, and the midline of the highest point of arch section 4-2 is different from the horizontal connection line. Coincidentally, in this embodiment, preferably, the highest point of the elastic sheet 4 is biased outward.

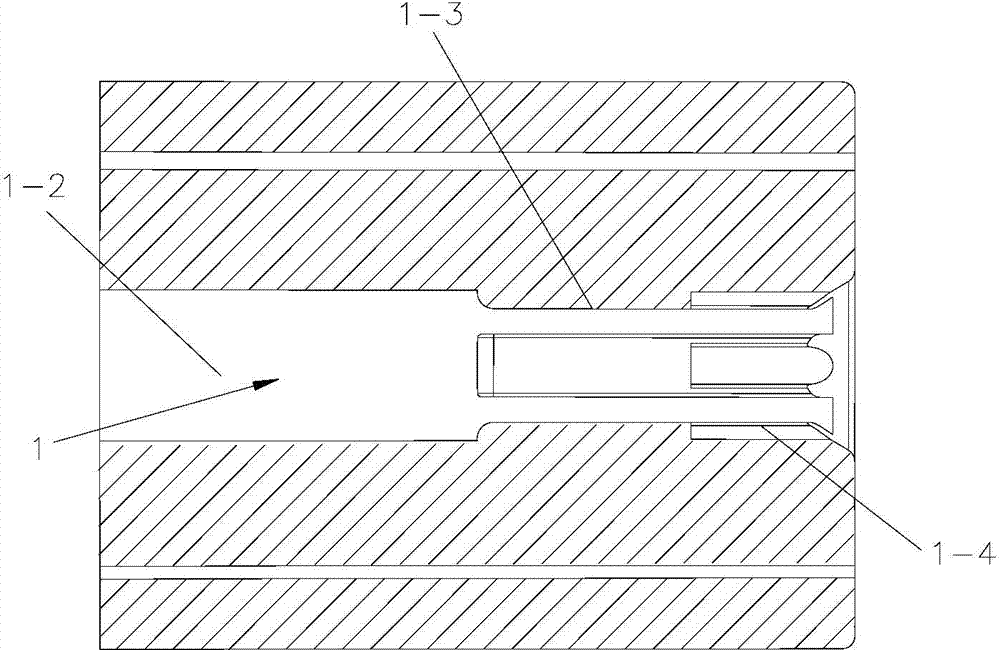

[0050] Such as Figure 6 , the front end of the output shaft 2 is hollow, the output shaft 2 has a through hole 3-1 communicating with the hollow part of the output shaft 2, the main part of the shrapnel 4 is placed in the hollow part of the output shaft 2, and the arch...

Embodiment 2

[0058] Such as Figure 9 , the elastic member in embodiment 2 adopts steel wire 5, and steel wire 5 has the characteristics of fast forming, and the structure of steel wire 5 is basically the same as that of shrapnel 4. After changing from shrapnel 4 to steel wire 5, its corresponding push rod 6 also has some changes. There are 4 limiting grooves 3 in the example, wherein there are through holes 3-1 on the two opposing limiting grooves 3, and there are two arched sections 4-2 of the steel wire 5, and the two arched sections 4-2 are connected to each other. Symmetrical, the two arched sections 4-2 protrude from the corresponding through holes 3-1 respectively, the push rod 6 has a tail part 6-7, and the tail part 6-7 is connected with the first journal 6-1, as Figure 10 , A notch 6-8 is provided on the tail part 6-7, and the rear section of the steel wire 5 is embedded in the notch 6-8, so that the rear section of the steel wire 5 is hooped on the end face of the first journal...

Embodiment 3

[0061] The difference between Embodiment 3 and Embodiment 1 lies in the unlocking mechanism. The unlocking mechanism of Embodiment 1 is to press the push rod 6 to cause radial deformation of the elastic member. This embodiment starts from another method (not shown) , using the method of rotating the push rod 6, the push rod is equipped with a cam, and the travel curve of the cam is used to make the shrapnel 4 open regularly or return to the normal state. When the shrapnel 4 is opened, the grinding head 1 cannot be removed , when the shrapnel 4 is in a non-expanded normal state, the grinding head can be quickly removed. In this way, the unlocking mechanism can also control the elastic member.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com