Wood veneer coiling automatic tensioning device

An automatic tensioning device, veneer technology, applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of veneer damage, unreliability, affecting product quality, etc. good roll effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

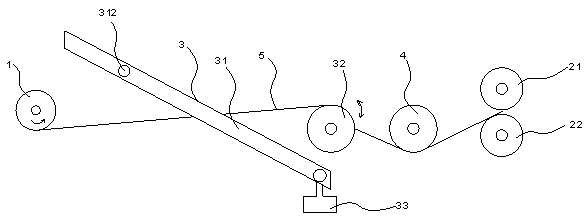

[0012] The present invention as Figure 1-2 As shown, it includes a winding roller 1 and a squeeze roller group, the squeeze roller group is located in front of the winding roller 1, and the squeeze roller group includes an upper squeeze roller 21 and a lower squeeze roller 22, so Between above-mentioned squeeze roller 21 and lower squeeze roller 22, be used for extruding veneer 5;

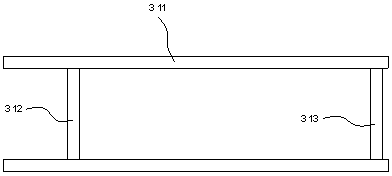

[0013] The automatic tensioning device 3 is connected between the winding roller and the squeeze roller group, the automatic tensioning device 3 includes a bracket 31, a guide roller 32 and a counterweight 33, a pair of vertical plates 311 of the bracket , a tension roller 312 and a rotating shaft 313, the tension roller 312 and the rotating shaft 313 are respectively connected between the pair of vertical plates 311, the tension roller 312 and the rotating shaft 313 are respectively located at the two ends of the support 31, the The tension roller 312 is located above the rotating shaft 313 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com