Plastic as well as production method and shell thereof

A technology of plastics and housings, applied in the field of materials, can solve the problems of not meeting the requirements of flame retardancy and heat resistance of information technology equipment, and the low flame retardancy and heat resistance of ABS plastics, so as to improve the flame retardancy and heat resistance The effect of thermal performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

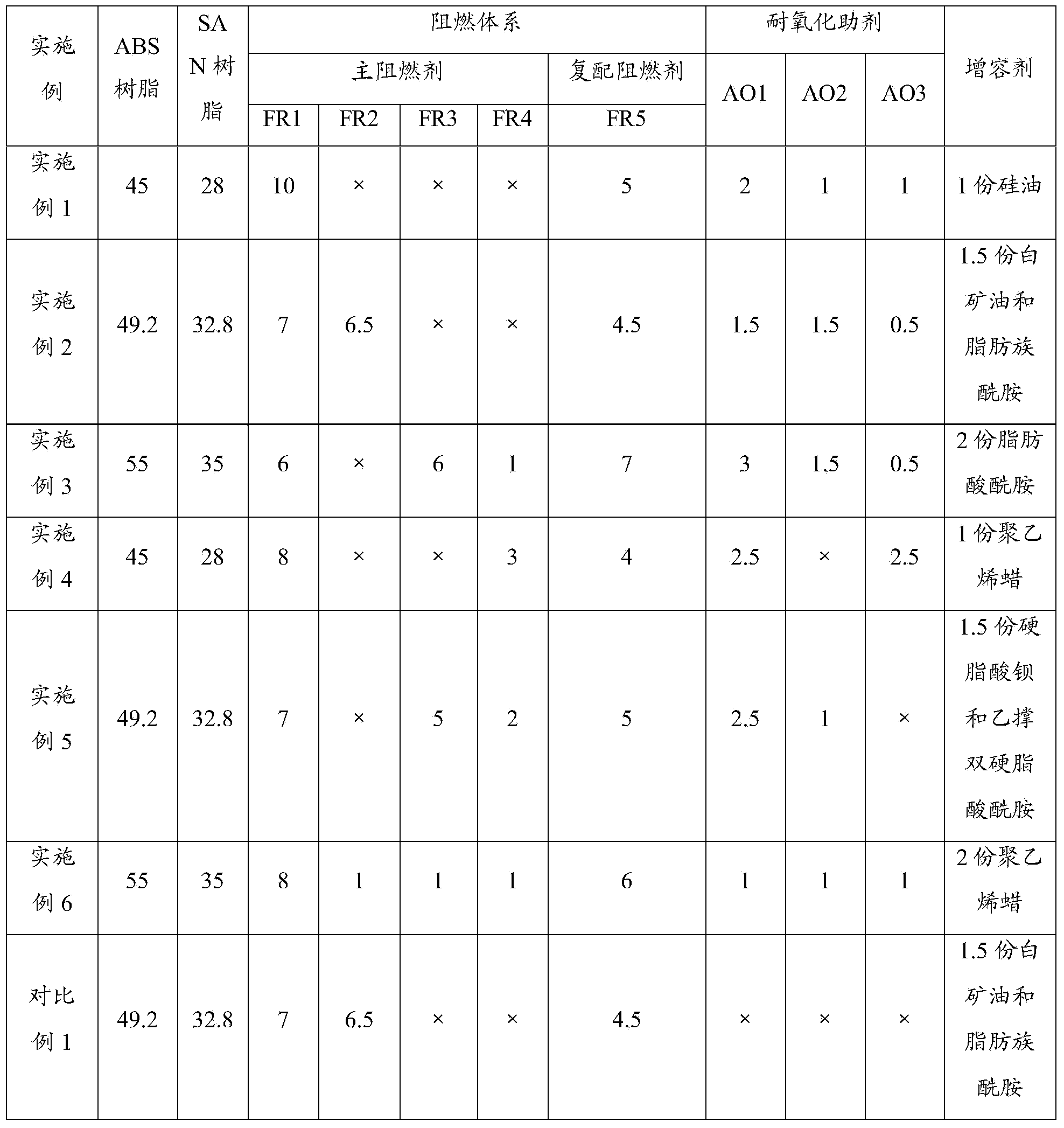

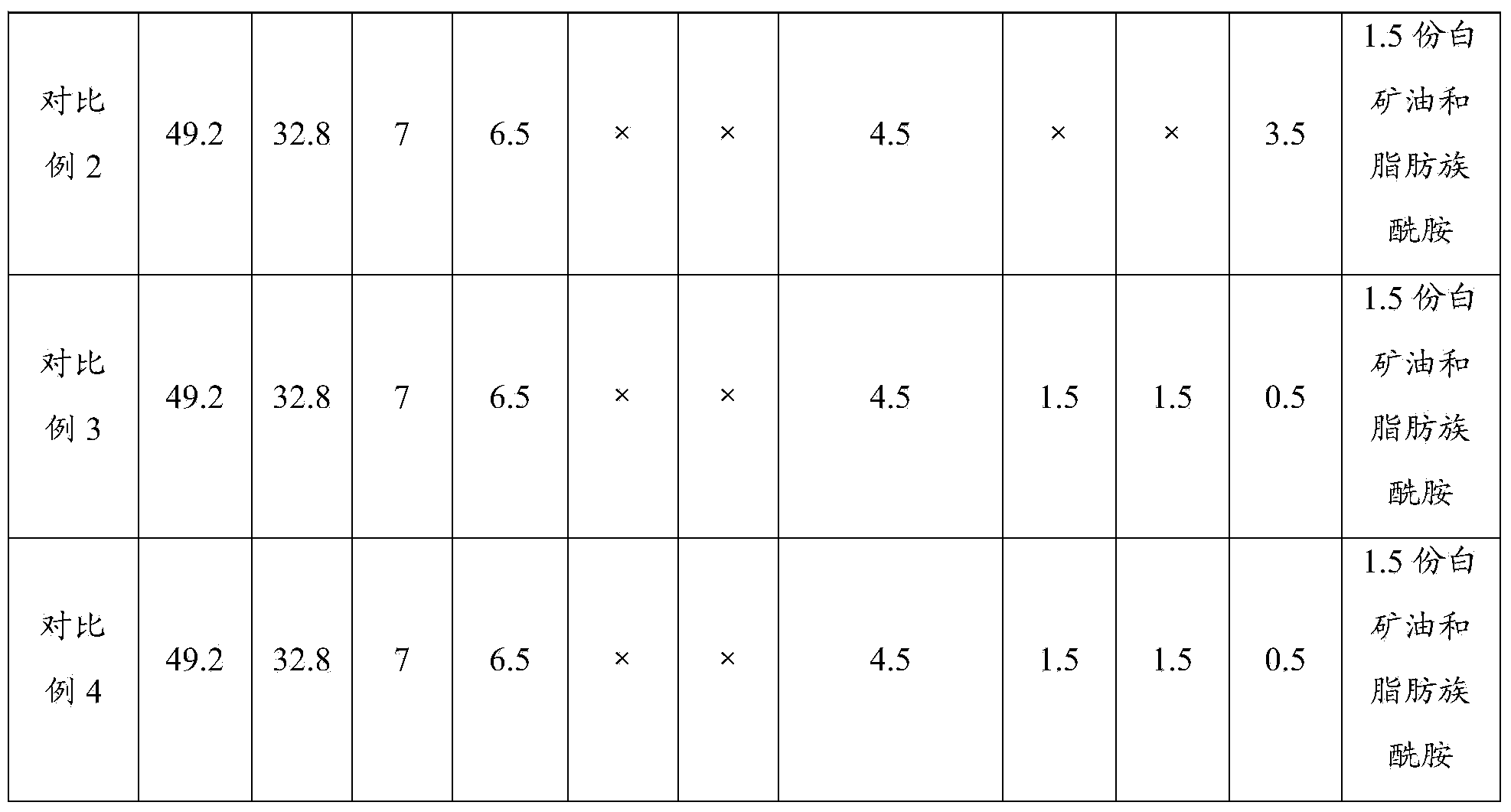

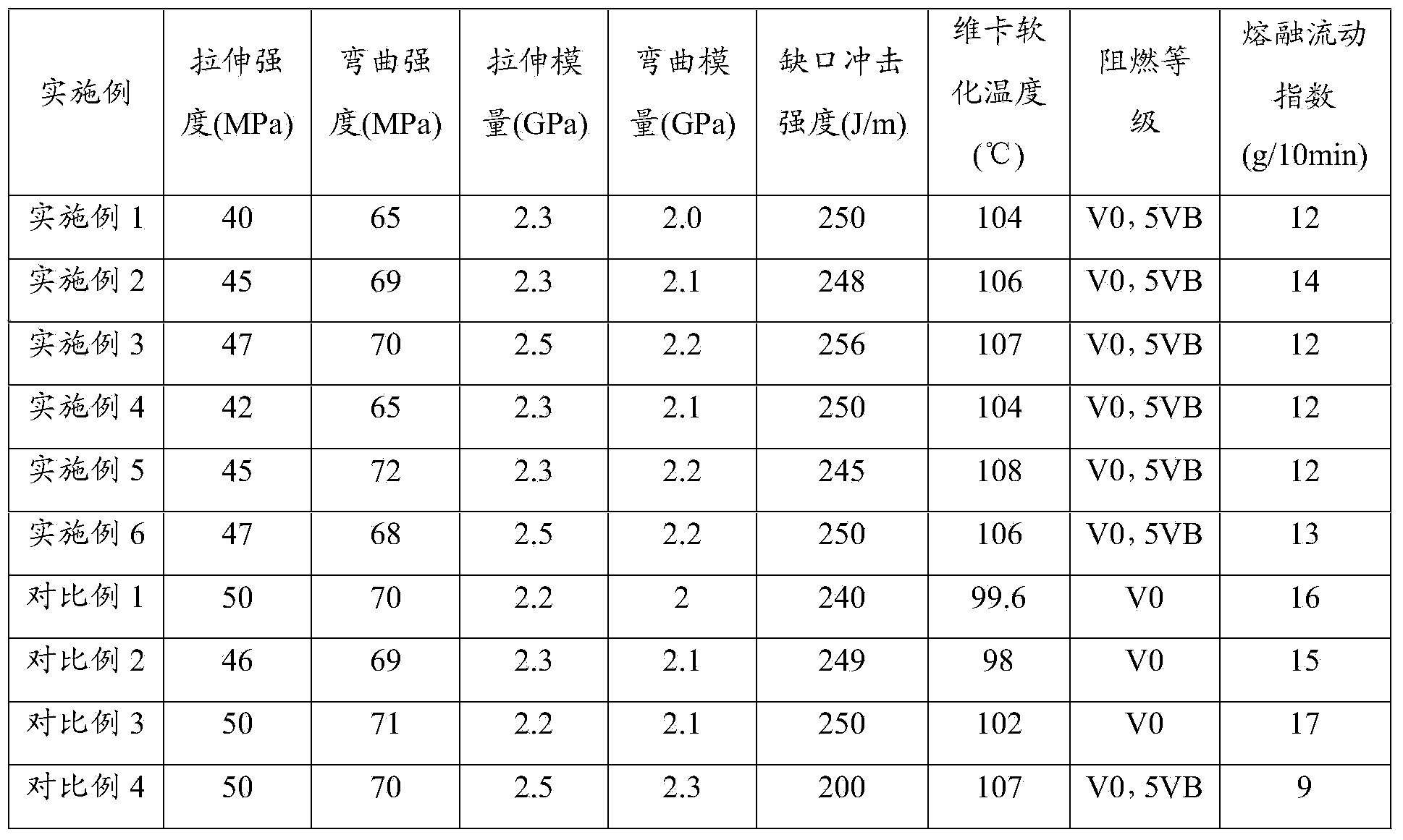

Embodiment Construction

[0009] In order to improve the flame retardancy and heat resistance of plastics, the embodiments of the present invention provide a plastic, a manufacturing method thereof, and a housing. In the technical solution of the present invention, the plastic contains a flame retardant system and an oxidation-resistant additive synergistic with the flame retardant system, which can improve the flame retardant grade of the plastic to 5VB, and the heat resistance of the plastic is also greatly improved, which is expressed as Vicat softening temperature Above 100°C, the casing made of the plastic can meet the requirements of safety regulations for information technology equipment. In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail by taking non-limiting examples as examples below.

[0010] Embodiments of the present invention firstly provide a plastic, including:

[0011] 45 to 55 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com