Mixed refrigerant

A mixed refrigerant, mass percentage technology, used in sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve the problems of small volumetric cooling capacity, low energy efficiency, large temperature slip, etc. Low, improve the energy efficiency ratio, reduce the effect of charging

Inactive Publication Date: 2014-12-24

SINOCHEM LANTIAN +1

View PDF5 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The refrigerant compositions disclosed in the above-mentioned patents have high GWP values, strong flammability, large temperature glide, low energy efficiency, small volumetric refrigeration capacity, or cannot be directly charged and applied to HFC- 134a system and other shortcomings, so it is necessary to develop refrigerants that have better refrigeration performance, better compatibility with existing systems, and better environmental performance for automotive air conditioning

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

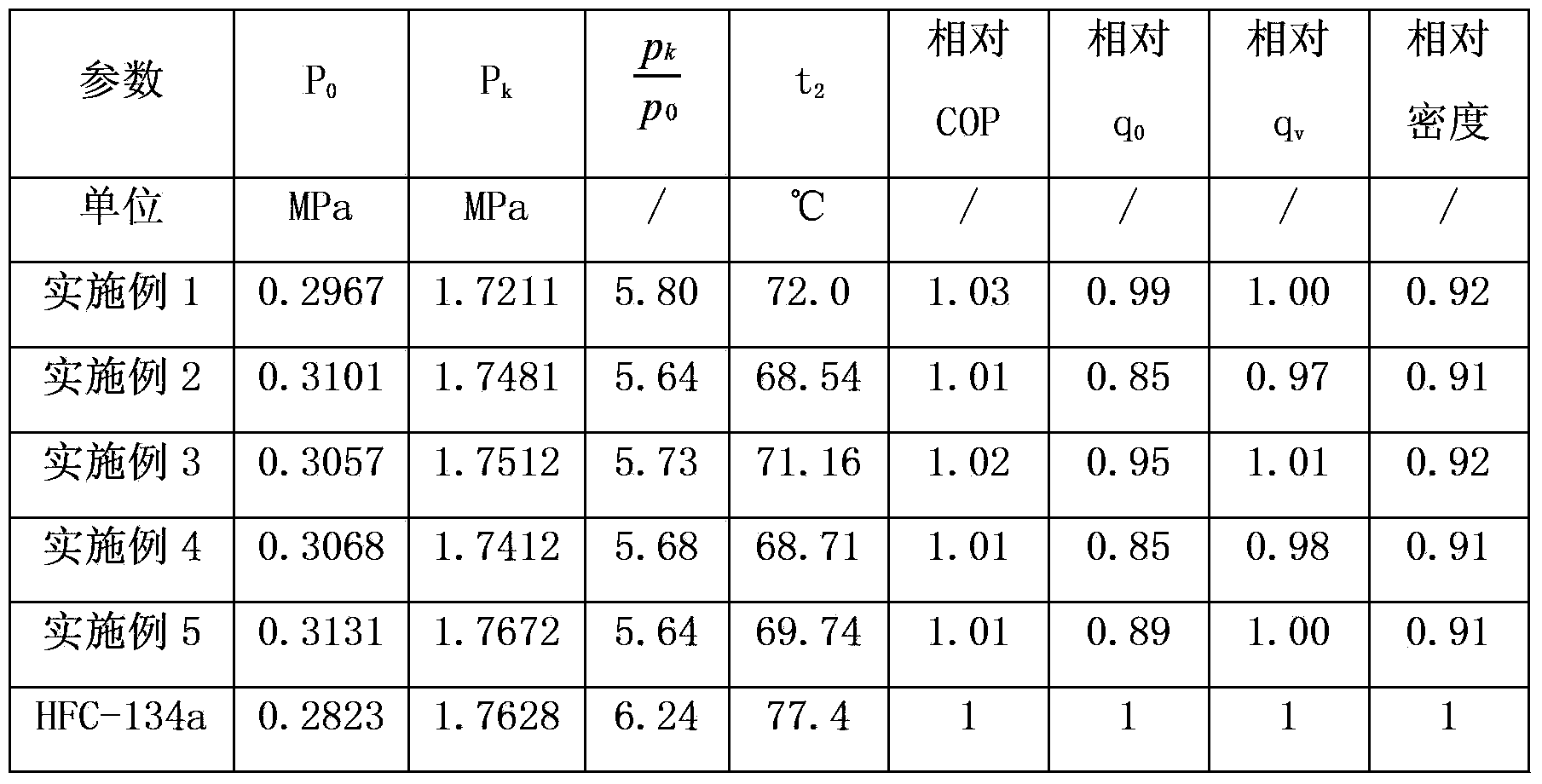

[0032] Example 1: HFO-1234yf, HFO-1234ze(E) and HFE-143a were physically mixed in the liquid phase at a mass percentage of 52:30:18.

Embodiment 2

[0033] Example 2: Physically mix HFO-1234yf, HFO-1234ze(E) and HFE-143a in a liquid phase at a mass percentage of 90:5:5.

Embodiment 3

[0034] Example 3: Physically mix HFO-1234yf, HFO-1234ze(E) and HFE-143a in a liquid phase at a mass percentage of 65:20:15.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

| critical pressure | aaaaa | aaaaa |

| critical temperature | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a mixed refrigerant with GWP value being lower than 150. The mixed refrigerant comprises the following components in percentage by mass: 52%-90% of 2,3,3,3-tetrafluoropropene (HFO-1234yf), 5%-30% of Trans-1,3,3,3-tetrafluoropropene (HFO-1234ze(E)) and 5%-18% of F-methyl methyl (CF3OCH3 and HFE-143a). The mixed refrigerant does not damage atmospheric ozone layers, is low in greenhouse effect value, and excellent in environment-friendly performance; thermal performance of the mixed refrigerant is comparable with that of HFC-134a; drop-in substitution can be realized directly without change of any parts of an originally used HFC-134a system, the energy-efficiency ratio can be increased, the charging amount can be reduced, and the mixed refrigerant has the advantages of being low in substitution cost, resource-saving and energy-saving, and can be used as a long-term substitute of HFC-134a in an automobile air conditioner.

Description

technical field [0001] The invention relates to a mixed refrigerant, in particular to a refrigerant composition used in an automobile air-conditioning system which does not destroy the potential of atmospheric ozone and has extremely low greenhouse effect. Background technique [0002] 1,1,1,2-Tetrafluoroethane (HFC-134a), as a substitute for CFC-12, has been widely used for its excellent performance, but because of its high greenhouse effect value of 1430, it is " Kyoto Protocol "listed as one of the first high-GWP value refrigerants phased out. According to the requirements of the MAC Directive (2006 / 40 / EC) on emissions from automotive air-conditioning systems that the European Union has passed and came into effect in 2013, by the end of 2016, refrigerants with a GWP value greater than 150 must be phased out in proportion to the use of automotive air-conditioners. And from January 1, 2017, all automotive air conditioners will be prohibited from using refrigerants with a G...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09K5/04

CPCC09K5/045C09K2205/126C09K2205/22Y02P20/10

Inventor 郭智恺谢品赞

Owner SINOCHEM LANTIAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com