Stepping linkage transmission mechanism for quilt sewing machine

A technology of transmission mechanism and quilt sewing machine, which is applied in the direction of transmission device, sewing machine components, sewing machine control device, etc. It can solve the problems that affect the sewing effect of quilt cover, it is difficult to achieve coordinated action, and is not connected, so as to achieve stable transmission, High degree of automation, with precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

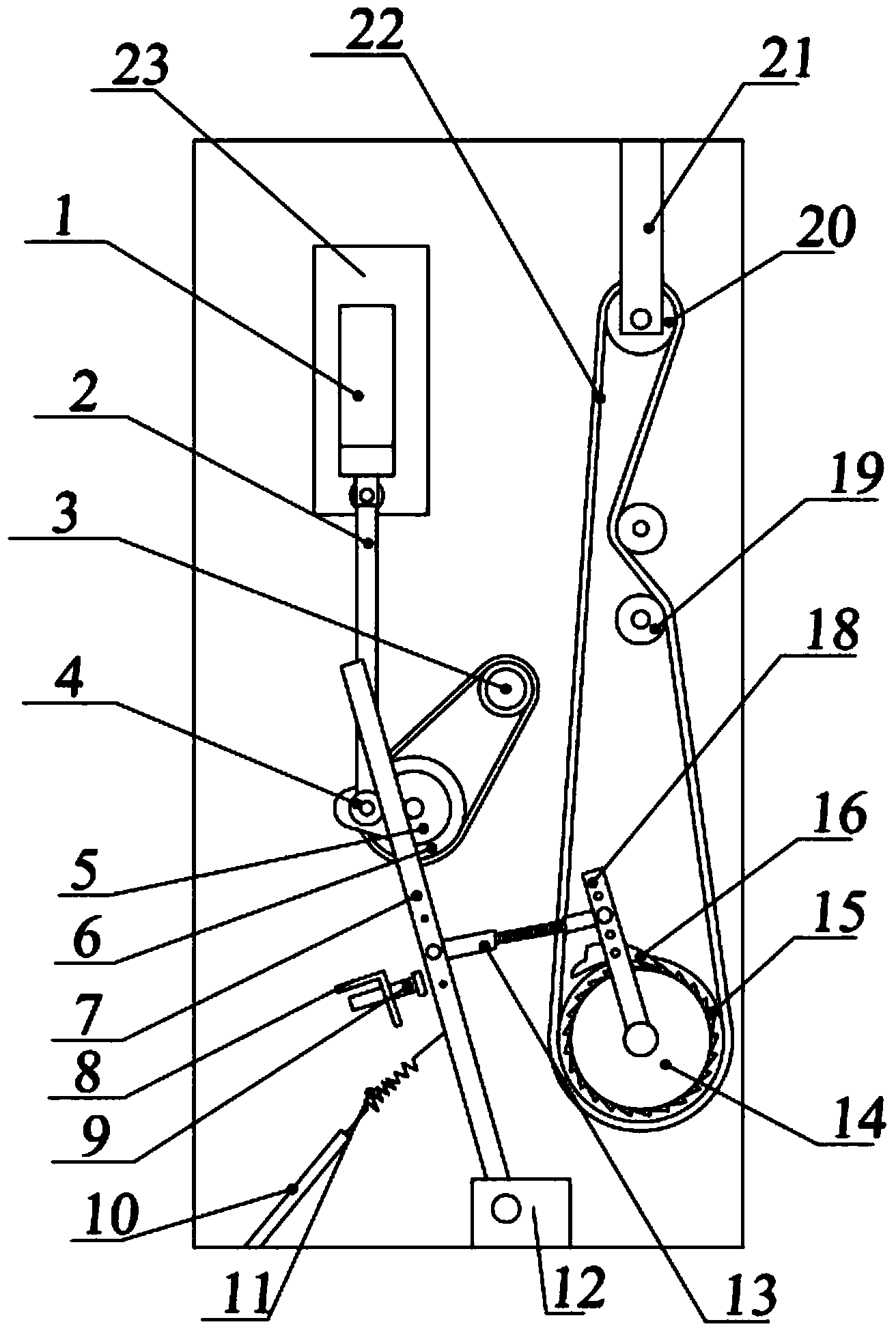

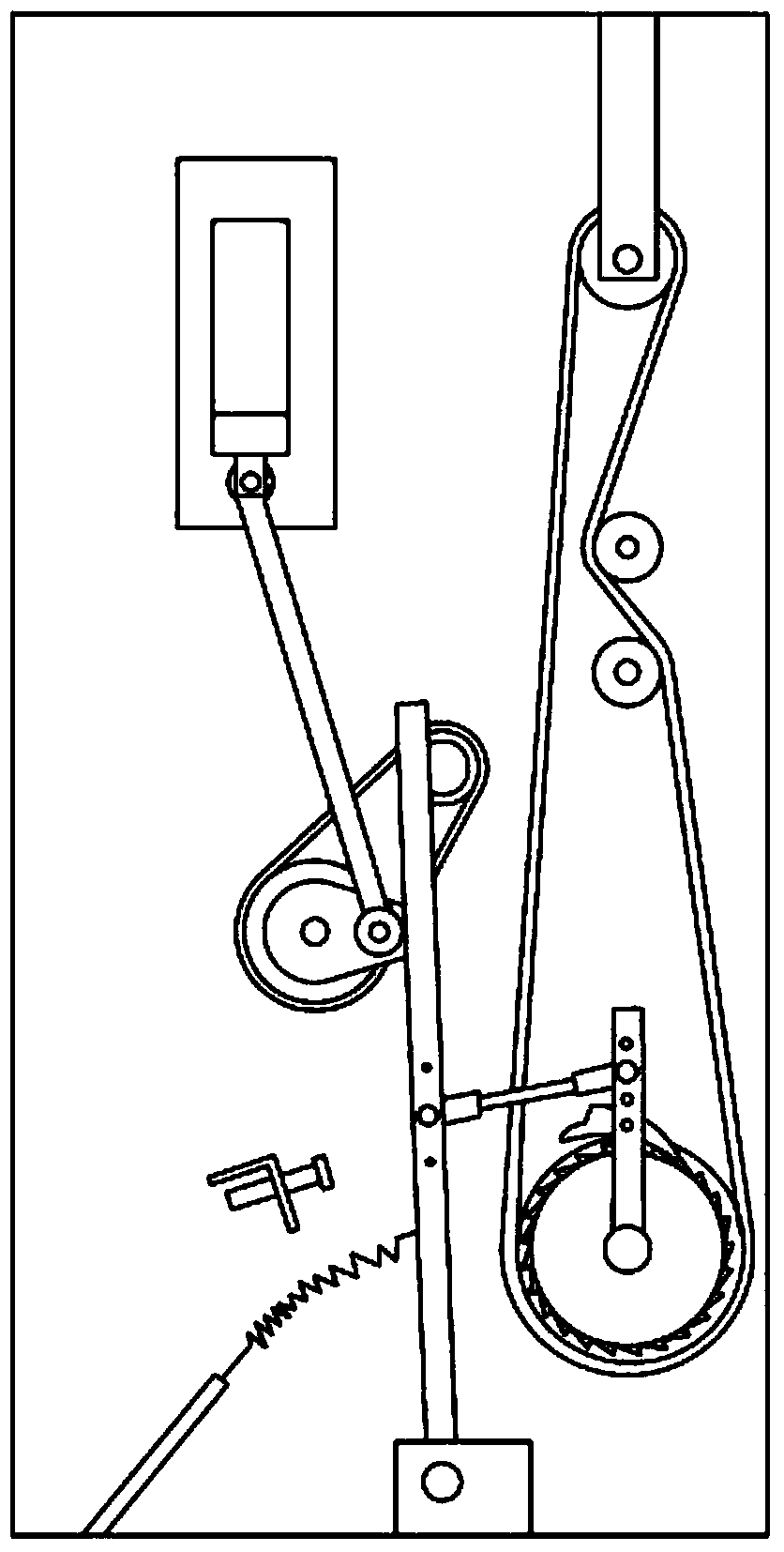

[0028] The motor output sprocket 3 is driven by the motor to rotate, and the motor output sprocket 3 drives the driving sprocket 6 and the cam 5 to rotate through the transmission chain 22, and the rotation of the cam 5 moves the lifting beam 1 up and down through the transmission of the connecting rod 2;

[0029]While the cam 5 is rotating, the end of the connecting rod 2 connected to the cam 5 makes a circular motion, driving the rocking arm 7 that is always close to it to swing back and forth. The stepping rocker arm 18 swings to the rightmost end synchronously. In this process, the outer side of the arc-shaped top block 16 and the stepping wheel 14 pushes the stepping wheel 14 to rotate to realize a stepping rotation. The stepping wheel 14 and the stepping sprocket 15 rotates synchronously, so the rotation of the stepping sprocket 15 drives the two roller sprockets 19 to rotate through the transmission chain 22. Since the transmission chain 22 is in an S shape and walks aro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com