Cam-linkage thumbing mechanism of multi-shot primer ignition quality tester

A technology of cam linkage and toggle mechanism, which is applied in ammunition testing, mechanical equipment, transmission devices, etc. It can solve the problems of complicated operation and low work efficiency, and achieve the effects of improving work efficiency, saving time and using stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

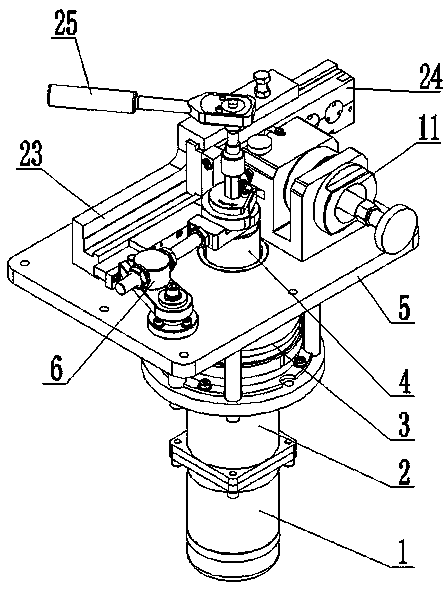

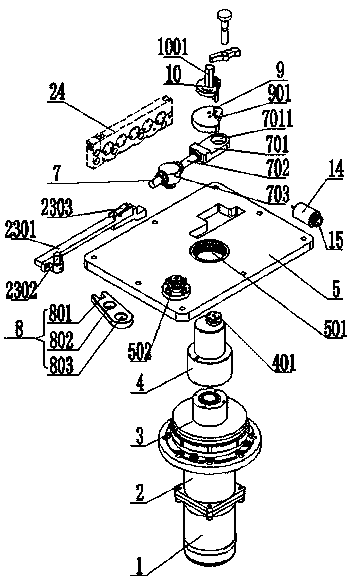

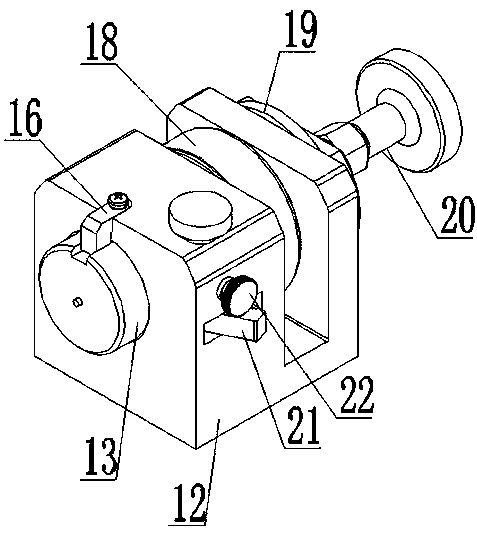

[0023] Such as figure 1 , figure 2As shown, a cam link toggle mechanism of a multi-burst primer ignition tester of the present invention includes an organic base 5, a connecting rod assembly 6, a rear body 11, a front body 23 and a multi-burst primer conveying clip 24, and a rear body 11 and the front body 23 are all connected on the top surface of the machine base 5, the multi-fire primer delivery clip 24 is slidably connected on the front body 23, the rear body 11 is arranged on the side of the front body 23, and the front body 23 side is slidably connected with a primer clip push rod 2301, the front and rear ends of the primer clip push rod 2301 are respectively connected with a pawl 2303 and a toggle shaft 2302, and a spring is connected between the ratchet 2303 and the primer clip push rod 2301, and multiple bursts of primers are mounted on the clip 24. Bottom fire, a plurality of primer linear arrays, a plurality of pawl grooves at the bottom of the multi-fire primer d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com