Dryer with a waste heat recovery means

A waste heat recovery and dryer technology, applied in dryers, drying, household dryers, etc., can solve problems such as hindering heat transfer air flow, adverse effects on drying performance, etc., to reduce gas consumption, improve The effect of heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, embodiments of a dryer having a waste heat recovery unit according to the present invention will be described in detail with reference to the accompanying drawings.

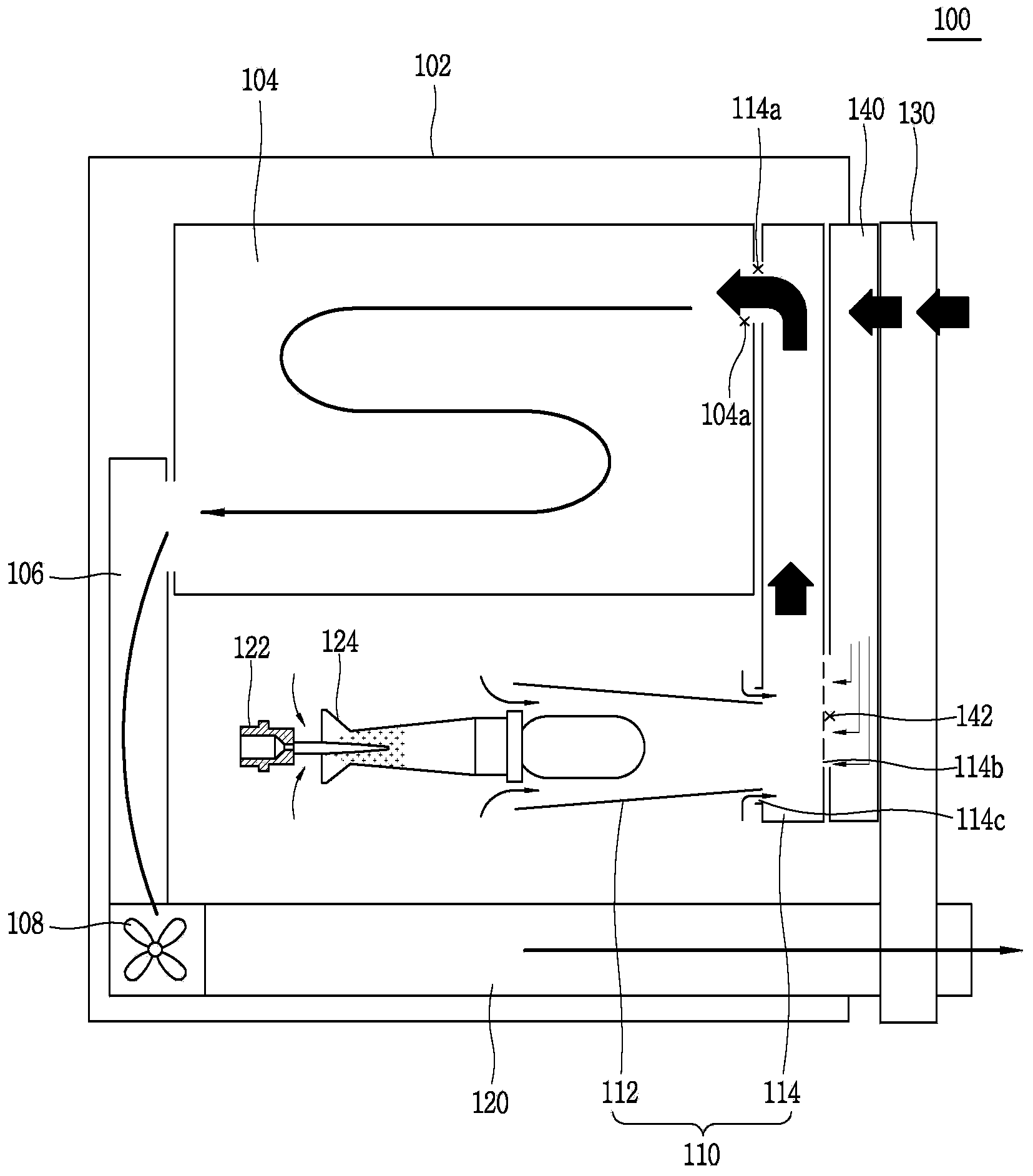

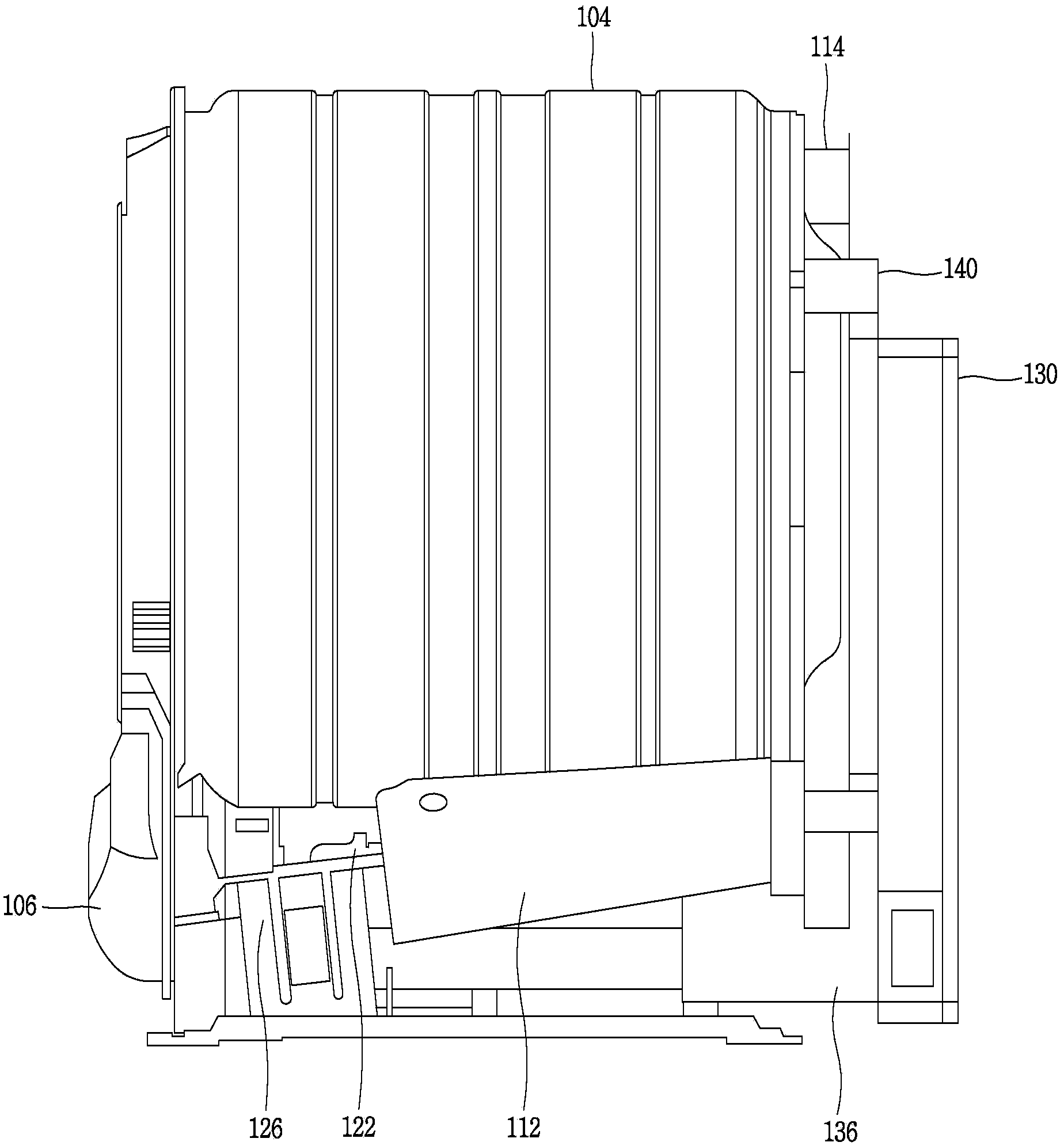

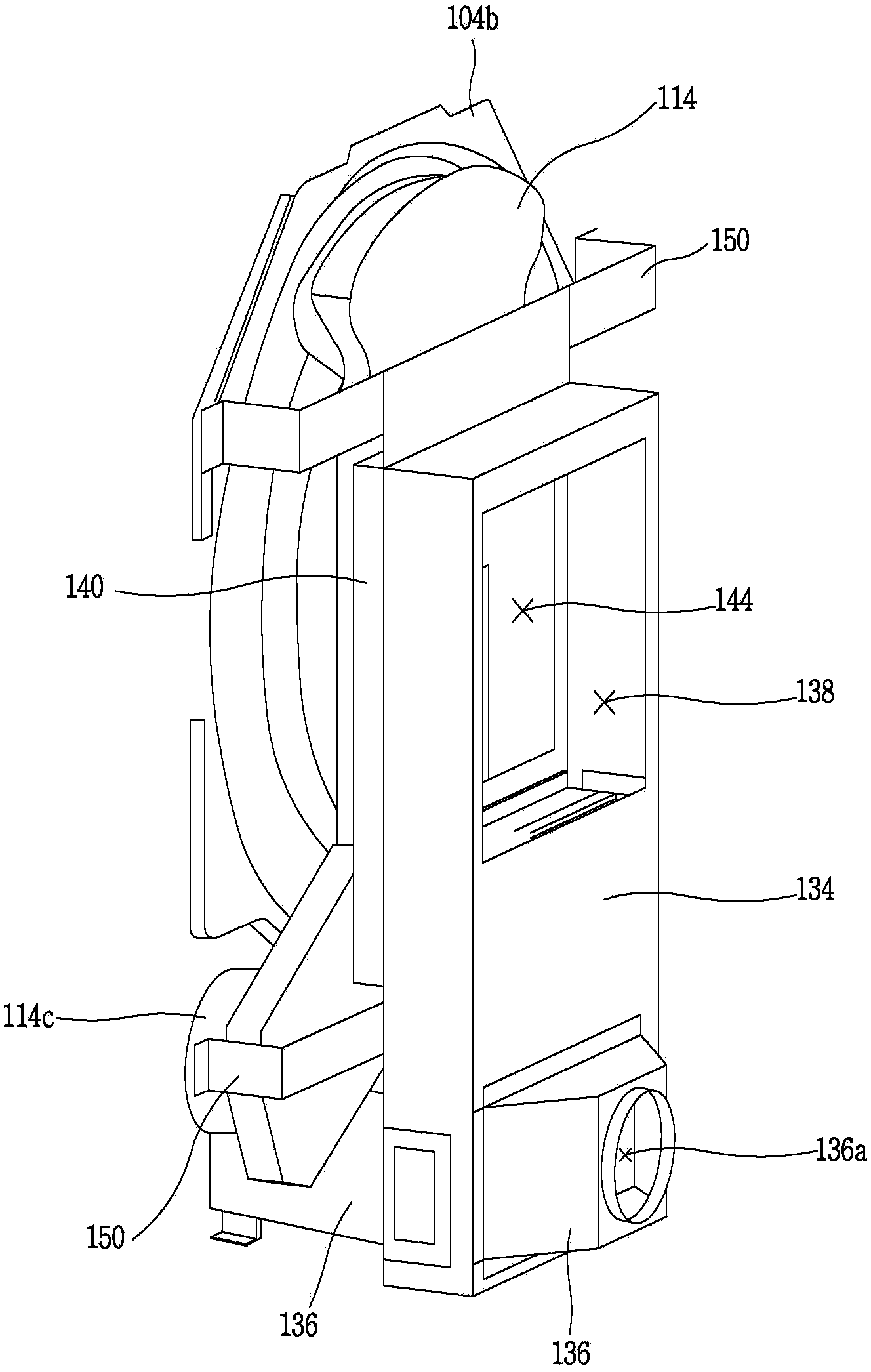

[0040] figure 1 A diagram briefly showing a first embodiment of a dryer with a waste heat recovery unit of the present invention, figure 2 In order to show the side view of the internal structure of the above-mentioned first embodiment, image 3 It is a perspective view showing the rear side of the drum in the first embodiment described above. refer to Figure 1 to Figure 3 The above-mentioned first embodiment 100 includes a housing 102 approximately in the shape of a regular hexahedron, and a drum 104 is rotatably installed inside the housing 102, and the drum 104 is used to input laundry as a drying object.

[0041] An air supply port 104a is formed on the upper side of the rear portion of the drum 104 to inject hot air for drying the laundry. The hot air supplied in this way passes thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com