Shock absorption and noise reduction structure for sonic logging tool

A logging instrument and sonic technology, applied in the field of shock absorption and noise reduction structures, can solve the problems of sonic logging noise interference and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

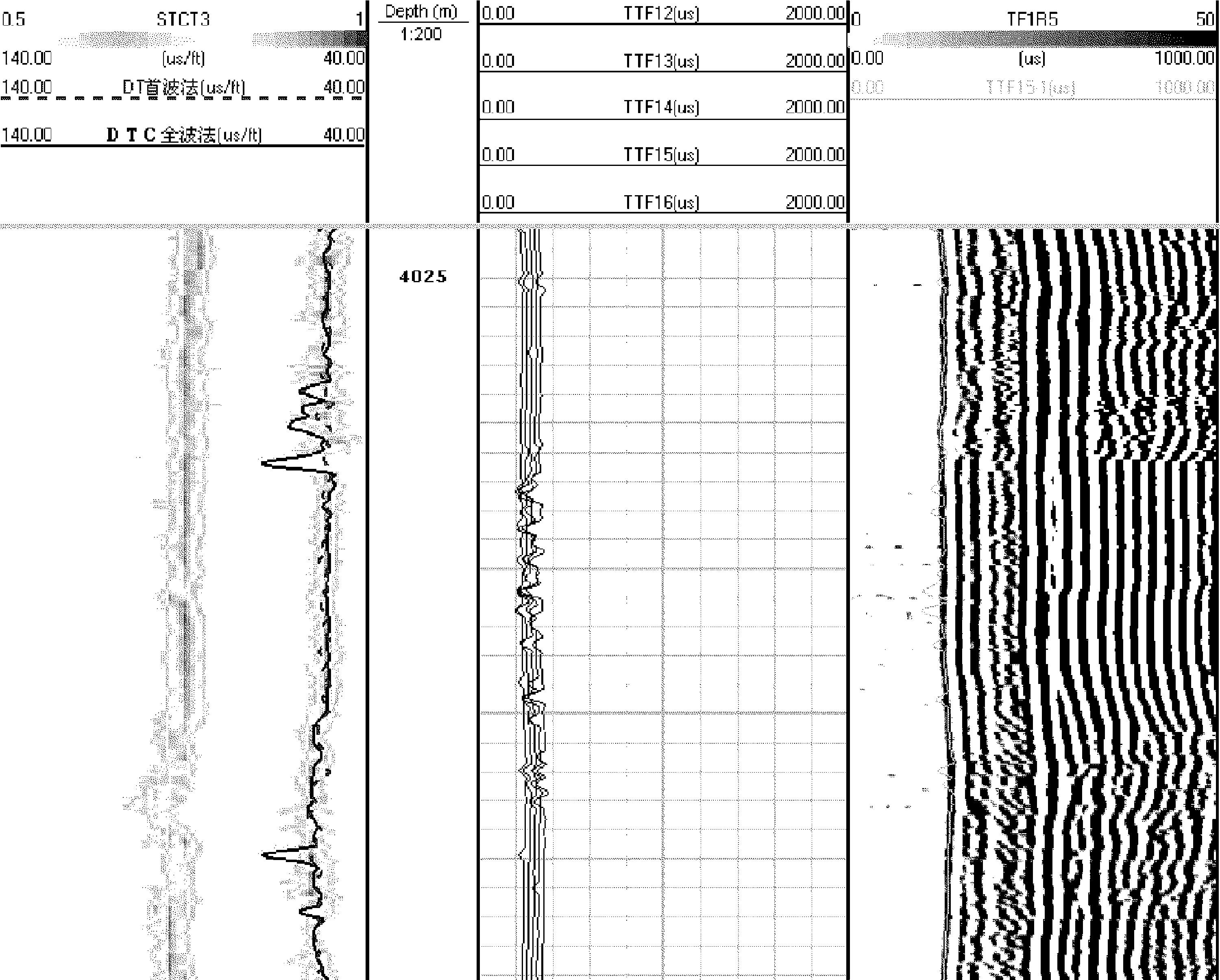

Image

Examples

Embodiment Construction

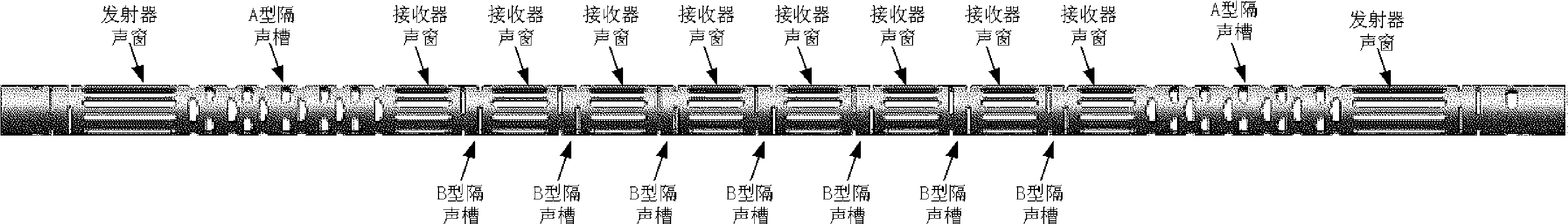

[0036] The embodiments of the present invention will now be described more fully with reference to the accompanying drawings. The following description is merely exemplary in nature, and does not limit the present invention and its application or use.

[0037] The present invention will now be further described with reference to the drawings. reference Figure 4 , Which is the instrument housing. It can be seen that the outer diameter of the sound system of conventional acoustic wave instruments is the same as that of other instruments. The file-shaped sound insulation groove is designed to attenuate direct waves. In horizontal well logging, the friction with the borehole wall produces noise. Main source. The direct wave here refers to the sound wave emitted by the transmitting transducer, which is directly transmitted to the receiver along the sound system housing and generated by the sound wave signal. When manufacturing sonic logging tools, it is required that the direct wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com