A green and efficient transportation method for underground coal mines

A transportation method, a green technology, applied in the direction of earthwork drilling, slitting machinery, etc., can solve the problems that the belt conveyor occupies a large area, is not easy to turn and transport, and the coal is easy to fall off, so as to reduce costs and transportation requirements, green transportation , the effect of reducing safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following are specific embodiments of the present invention and the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

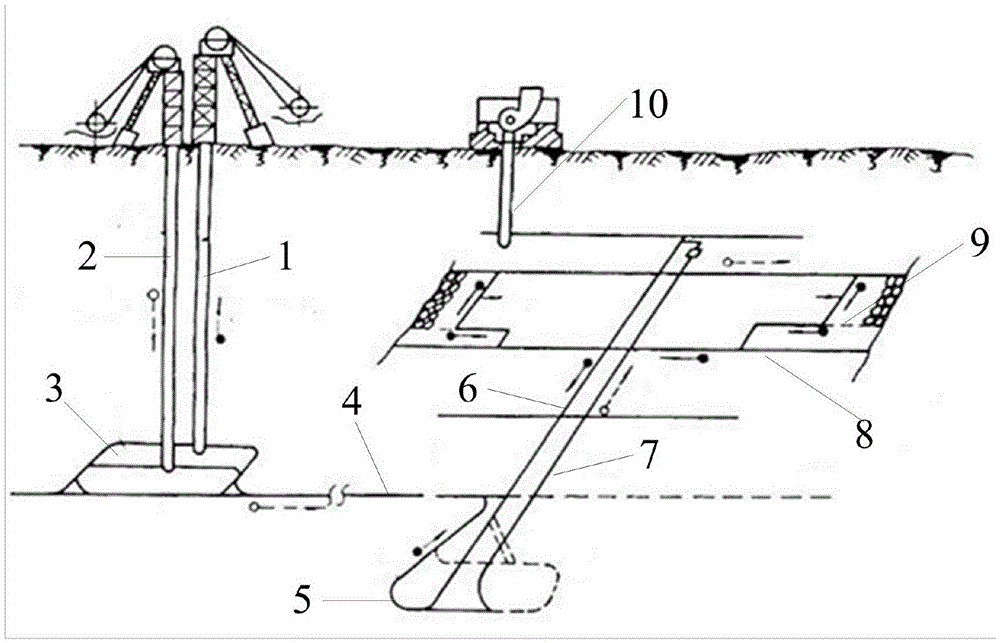

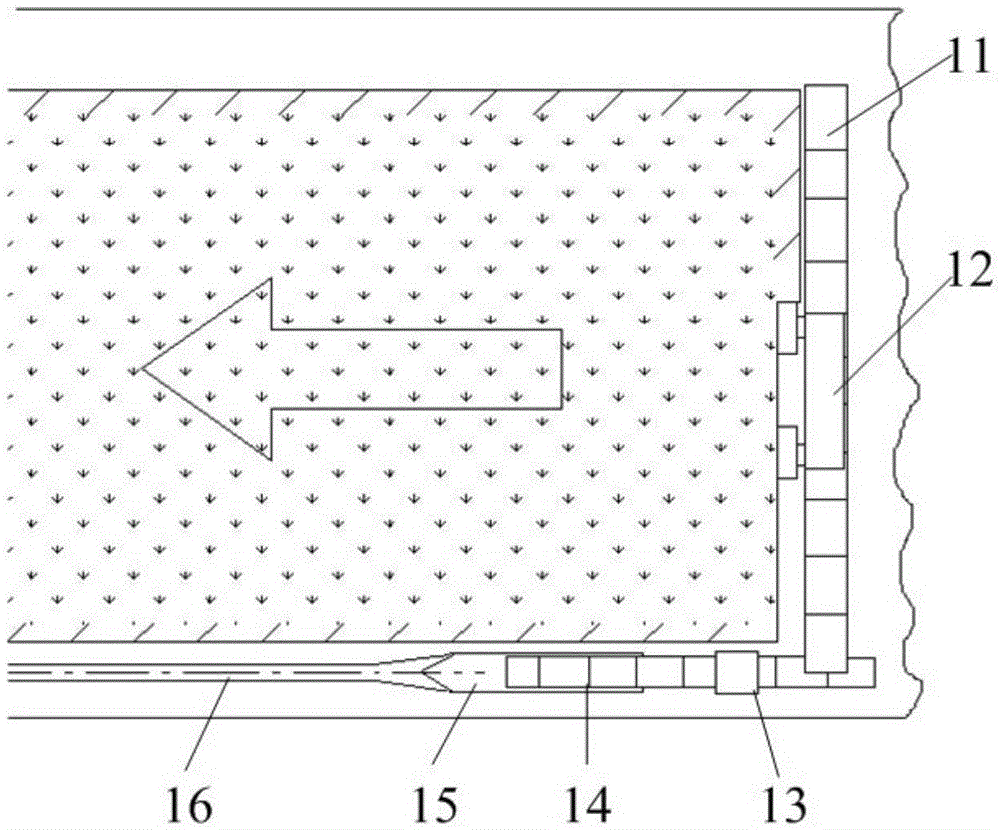

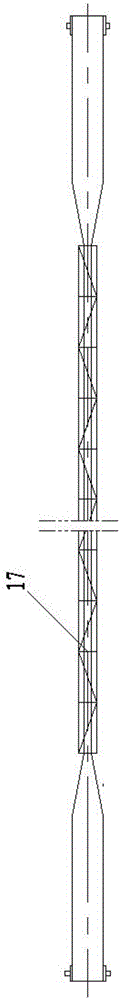

[0014] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a new green and efficient transportation method for underground coal mines. The roadway layout is mainly composed of the main shaft 1, the auxiliary shaft 2, the bottom parking lot 3, the transportation lane 4, the stone gate 5, the transportation uphill 6, the track uphill 7, and the trough 8 , mining working face 9, wind shaft composition 10; the transportation equipment under the mine is mainly composed of scraper conveyor 11, coal shearer 12, secondary crusher 13, bridge type transfer machine 14, self-moving tail 15, retractable The tubular belt conveyor 16, the tubular belt conveyor 17 and the bendable tubular belt conveyor 18 are composed; the coal shearer 12 and the scraper conveyor 11 are arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com