A system and method for displacing high-pressure coal seam gas with low-medium pressure air

A coal seam gas and air flooding technology, which is applied in the direction of gas discharge, earth drilling, mining fluid, etc., can solve the problems of gas injection hole sealing that cannot meet the requirements and safety hazards, so as to reduce the gas content, ensure safety, The effect of shortening the pre-drawing period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

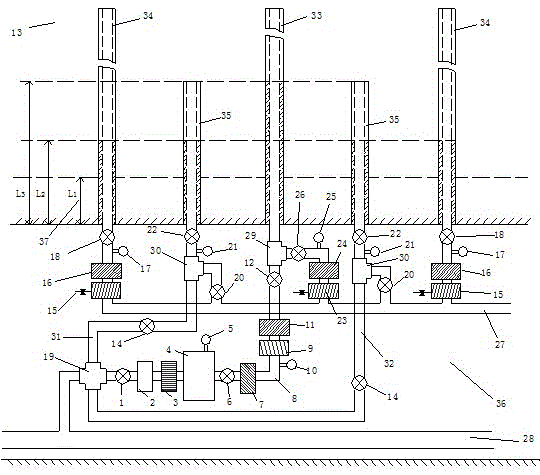

[0034] Embodiment: The sampling device in this embodiment is a sampling valve. as attached figure 1 As shown, a low-medium pressure air displacement high-pressure coal seam gas system is characterized in that it consists of a gas compression system and an air extraction system. The gas compression system includes a main pipeline and a branch pipeline, and a dehumidifier, a booster valve, Gas storage tanks, pressure reducing valves, pressure gauges, throttle valves and flowmeters; the main pipeline penetrates into the sealing section of the gas injection hole in the coal seam; the branch pipeline penetrates into the sealing section of the small hole in the coal seam; the main pipeline and the extraction pipe The gas extraction system includes a drainage pipeline, which is equipped with a sampling valve, a flow meter and a pressure gauge, and two of the drainage pipelines penetrate into the sealing section of the extraction hole in the coal seam.

[0035] Further, there are two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com