Piston ring for car air conditioning compressor

A technology for air-conditioning compressors and piston rings, which is applied to mechanical equipment, machines/engines, and liquid displacement machinery, etc. It can solve the problems of high manufacturing cost, large leakage, and complex production processes, and improve the sealing of piston rings. Performance, improved service life, improved oil storage effect

Inactive Publication Date: 2014-12-24

仪征天华活塞环有限公司

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The second type omits the piston ring. The advantages of PTFE composite materials are corrosion resistance, wear resistance and strong self-lubrication. However, with the wear of PTFE on the outer cylindrical surface of the piston (or coated with Teflon coating) , the gap between the piston and the ring cylinder increases, and the leakage is relatively large and the sealing performance is poor. On the other hand, a layer of polytetrafluoroethylene composite material (or Teflon coating) is coated on the outer cylindrical surface of the piston. A large amount of toxic gas will be produced in the process, which will cause problems such as complicated workmanship and high manufacturing cost.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

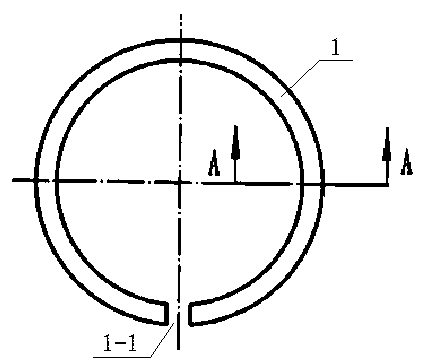

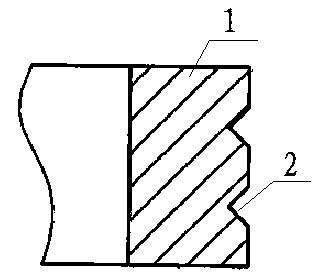

[0010] Such as figure 1 , 2 As shown, the main body of the present invention is a C-shaped ring body 1 provided with an opening 1-1. On the ring body 1, two V-shaped grooves 2 that are continuous along the outer circular surface of the ring are opened, and the two V-shaped grooves 2 They are respectively arranged at the upper and lower parts of the ring body 1 height.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a piston ring for a car air conditioning compressor. The piston ring for the car air conditioning compressor comprises a C-shaped ring body with an opening, wherein the ring body is provided with V-shaped grooves which are continuous along the external circular surface of the ring body. On one hand, the sealing property of the piston ring is improved, and on the other hand, the oil storage performance is improved; good lubrication is guaranteed in the absence of lubrication, the purpose of resisting cylinder scoring can be achieved, the wear of the ring and the cylinder is reduced, and the service life of the ring and the cylinder is prolonged.

Description

technical field [0001] The invention relates to the technical field of air-conditioning refrigeration compressors, in particular to a piston ring for car air-conditioning compressors. Background technique [0002] At present, there are two types of piston rings for piston car air-conditioning compressors. The first type is cast iron piston rings used in conjunction with the piston, and the second type is coated with a layer of polytetrafluoroethylene composite material (or coated with Teflon coating). The second type omits the piston ring. The advantages of PTFE composite materials are corrosion resistance, wear resistance and strong self-lubrication. However, with the wear of PTFE on the outer cylindrical surface of the piston (or coated with Teflon coating) , the gap between the piston and the ring cylinder increases, and the leakage is relatively large and the sealing performance is poor. On the other hand, a layer of polytetrafluoroethylene composite material (or Te...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F04B39/00

Inventor 张桂田陈玉元

Owner 仪征天华活塞环有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com