Blade rotating compressor

A compressor and casing technology, applied in the field of compressors, can solve problems such as small compression volume, leakage between sliding vane and cylinder wall, large friction and wear, and pulsation of air flow, so as to increase energy conversion efficiency and increase energy conversion Good results in efficiency, sealing and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

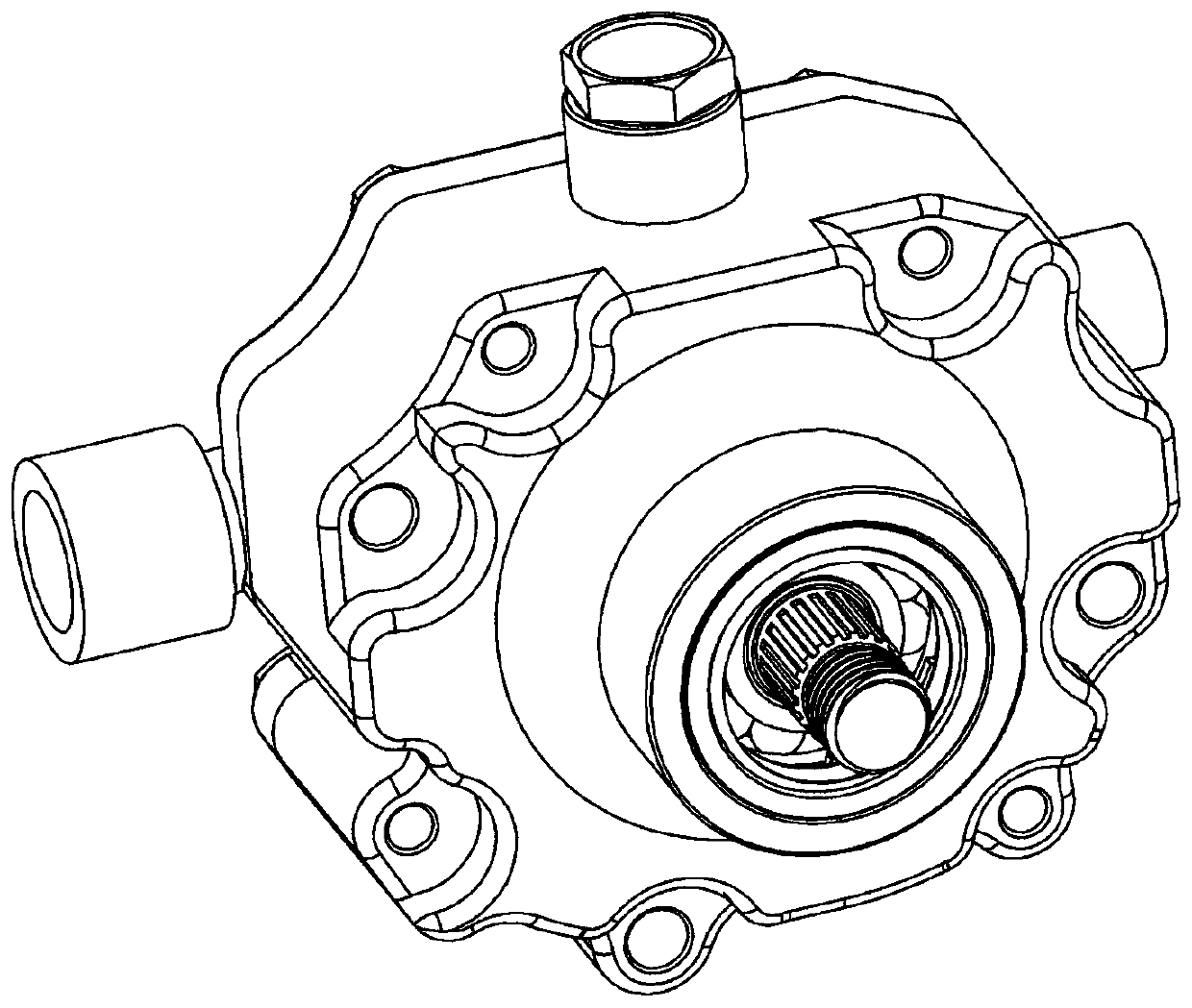

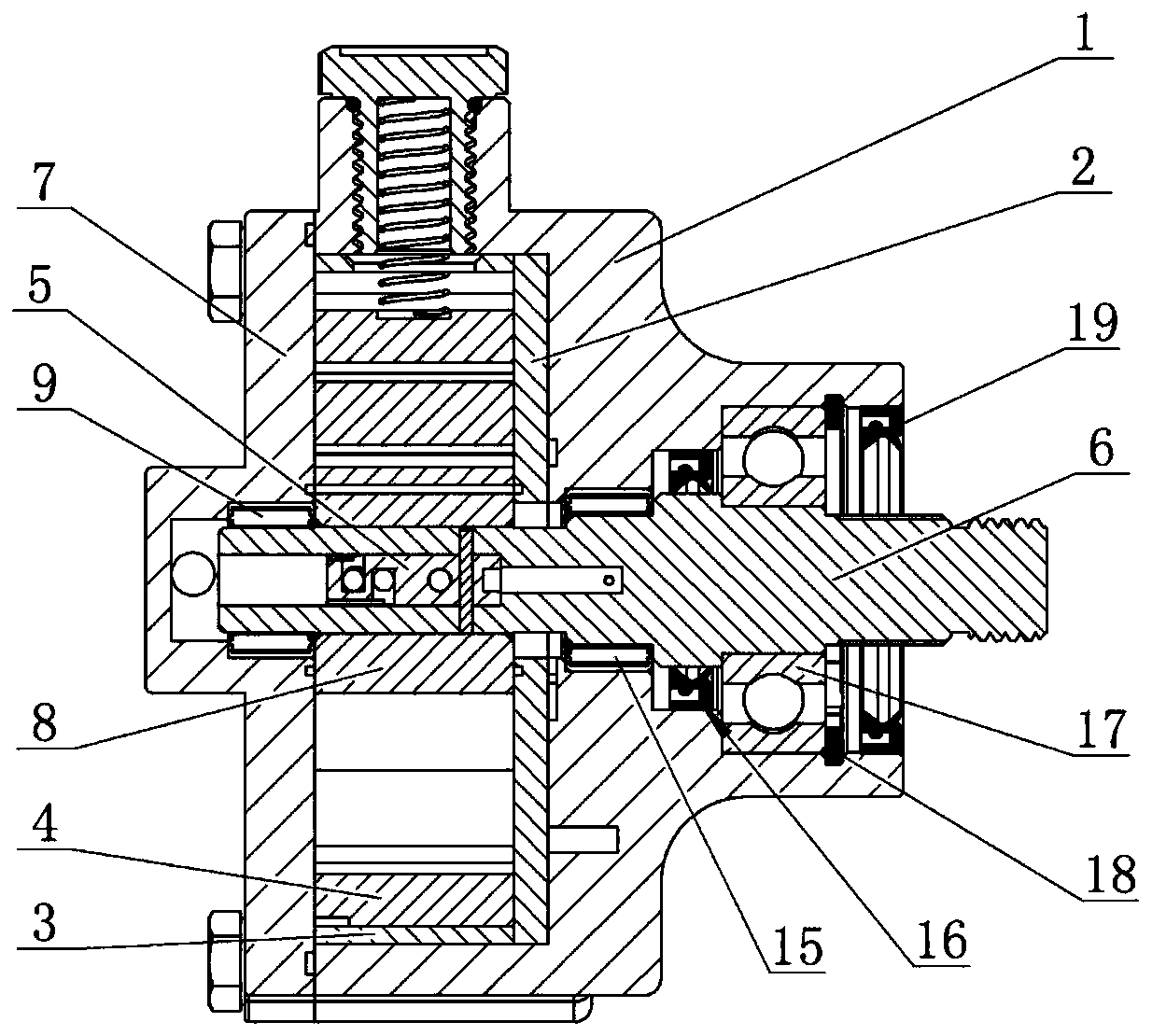

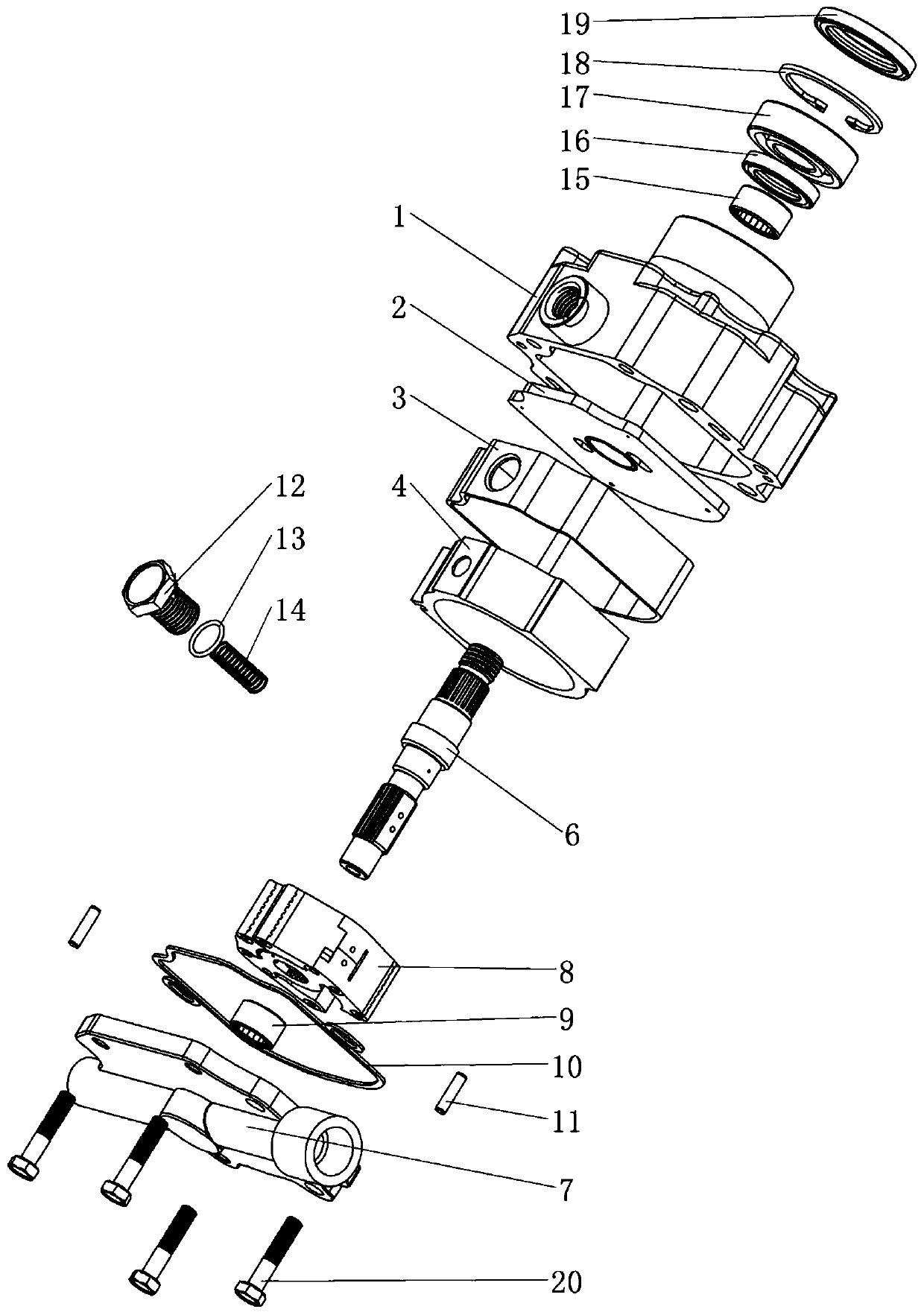

[0061] Various components of a rotary engine.

[0062] Such as figure 1 , 2 , 3, 4, 5, 14, 21, 25, this compression is made up of rotor assembly (8), casing assembly (59) (7), drive shaft assembly (60) three parts. and construct as Figure 31 The compression train (A) of the compressor shown, Figure 32 lubricating cooling system (B), Figure 4 The constant pressure system (C), figure 1 The external view of the compressor, figure 2 sectional view of the compressor, image 3 Compressor structure assembly diagram, Figure 4 It is a perspective view of the compressor structure.

[0063] Such as Figures 5 to 13 As shown, the components of the rotor assembly (8) include leaf A (22), leaf B (23), rotor seat (21), and the leaf (22) (23) and rotor seat (21) are connected through the leaf shaft (27) Hinged connection, the hinged seal is composed of the leaf shaft seal (28), and the two ends of the return spring (30) in the leaf shaft seal (28) are fixed in the corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com