Micromolecular active collagen peptide powder and preparation method thereof

A collagen peptide and collagen technology, which is applied to the field of small molecule active collagen peptide powder and its preparation, can solve the problems of complex proportioning process, poor absorption effect, and difficult production, and achieves simple process flow and production cost. Low, energy saving and environmental protection effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

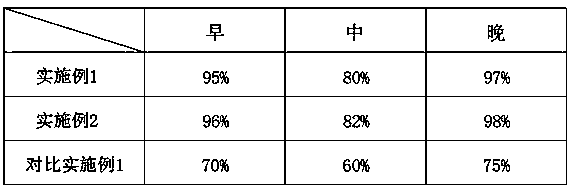

Embodiment 1

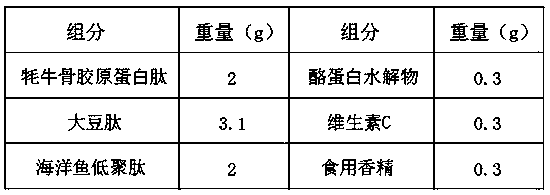

[0034] A small molecule active collagen peptide powder, the collagen peptide powder includes the following components by weight: raw materials and auxiliary materials;

[0035] The raw materials include the following components by weight: 2g of yak bone collagen peptide, 3.1g of soybean peptide and 2g of marine fish oligopeptide;

[0036] The auxiliary materials include the following components in parts by weight: 0.3g of casein hydrolyzate, 0.3g of vitamin C and 0.3g of food essence.

[0037] Further, the yak bone collagen peptide is prepared by the following steps:

[0038] S10. Pretreatment: remove impurities from fresh beef bones, remove periosteum and residual meat, etc., wash with flowing water and then dry;

[0039] S20, crushing: put the above-mentioned dried ox bone into a pulverizer for crushing, and pass through a 50-mesh sieve to obtain ox bone powder;

[0040] S30, high-pressure enzymatic hydrolysis: put the above-mentioned consumed bovine bone powder into an en...

Embodiment 2

[0057] A small molecule active collagen peptide powder, the collagen peptide powder includes the following components by weight: raw materials and auxiliary materials;

[0058] The raw materials include the following components by weight: 2g of yak bone collagen peptide, 3.1g of soybean peptide and 2g of marine fish oligopeptide;

[0059] The auxiliary materials include the following components in parts by weight: 0.3g of casein hydrolyzate, 0.3g of vitamin C and 0.3g of food essence.

[0060]Further, the yak bone collagen peptide is prepared by the following steps:

[0061] S10. Pretreatment: remove impurities from fresh beef bones, remove periosteum and residual meat, etc., wash with flowing water and then dry;

[0062] S20, crushing: put the above-mentioned dried ox bone into a pulverizer for crushing, and pass through a 100-mesh sieve to obtain ox bone powder;

[0063] S30, high-pressure enzymatic hydrolysis: put the above-mentioned consumed bovine bone powder into an en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com