Screen sealing adhesive tape and production process thereof

A production process and tape technology, which is applied in the field of screen sealing tape and its production process, can solve the problems of damage to electronic components, high rework costs, and inability to withstand high temperature and high humidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

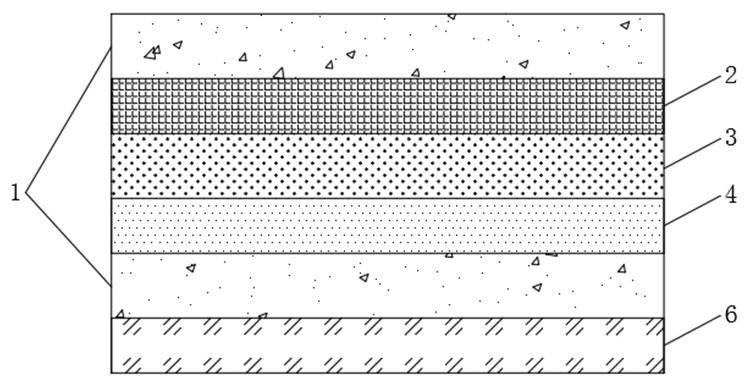

[0029] see Figure 1-3 , the present invention provides the following technical solutions: sealing tape, including TPU film 2, foam base material 3 and black PET film 4, external adhesives are used between TPU film 2, foam base material 3 and black PET film 4 For bonding and fixing, the outer surfaces of the TPU film 2 and the black PET film 4 are respectively coated with acrylic glue 1 , and the outside of the black PET film 4 is also bonded and fixed with a PET release film 5 through the acrylic glue 1 .

[0030] The production process of the sealing tape comprises the following steps:

[0031] S1. Production of T0.02 thick black non-substrate adhesive film: use 50U*1120mm BOPP double-sided release film to directly glue 0.02mm thick glue, and the effective width of glue is 1040mm;

[0032] S2. Production of semi-finished products of T0.74 thick black foam PU composite material: Use the T0.02mm black non-substrate adhesive film produced in step S1, and directly coat the surf...

Embodiment 2

[0042] see Figure 1-3 , the present invention provides the following technical solutions: sealing tape, including TPU film 2, foam base material 3 and black PET film 4, external adhesives are used between TPU film 2, foam base material 3 and black PET film 4 For bonding and fixing, the outer surfaces of the TPU film 2 and the black PET film 4 are respectively coated with acrylic glue 1 , and the outside of the black PET film 4 is also bonded and fixed with a PET release film 5 through the acrylic glue 1 .

[0043] The production process of the sealing tape comprises the following steps:

[0044] S1. Production of T0.02 thick black non-substrate adhesive film: use 50U*1120mm BOPP double-sided release film to directly glue 0.02mm thick glue, and the effective width of glue is 1040mm;

[0045] S2. Production of semi-finished products of T0.74 thick black foam PU composite material: Use the T0.02mm black non-substrate adhesive film produced in step S1, and directly coat the surfac...

Embodiment 3

[0055] see Figure 1-3 , the present invention provides the following technical solutions: sealing tape, including TPU film 2, foam base material 3 and black PET film 4, external adhesives are used between TPU film 2, foam base material 3 and black PET film 4 For bonding and fixing, the outer surfaces of the TPU film 2 and the black PET film 4 are respectively coated with acrylic glue 1 , and the outside of the black PET film 4 is also bonded and fixed with a PET release film 5 through the acrylic glue 1 .

[0056] The production process of the sealing tape comprises the following steps:

[0057] S1. Production of T0.02 thick black non-substrate adhesive film: use 50U*1120mm BOPP double-sided release film to directly glue 0.02mm thick glue, and the effective width of glue is 1040mm;

[0058] S2. Production of semi-finished products of T0.74 thick black foam PU composite material: Use the T0.02mm black non-substrate adhesive film produced in step S1, and directly coat the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com