A buncher

A continuously variable transmission, distance sensor technology, applied in the direction of vehicle gearbox, transmission control, transmission components, etc., can solve problems such as inability to torque control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

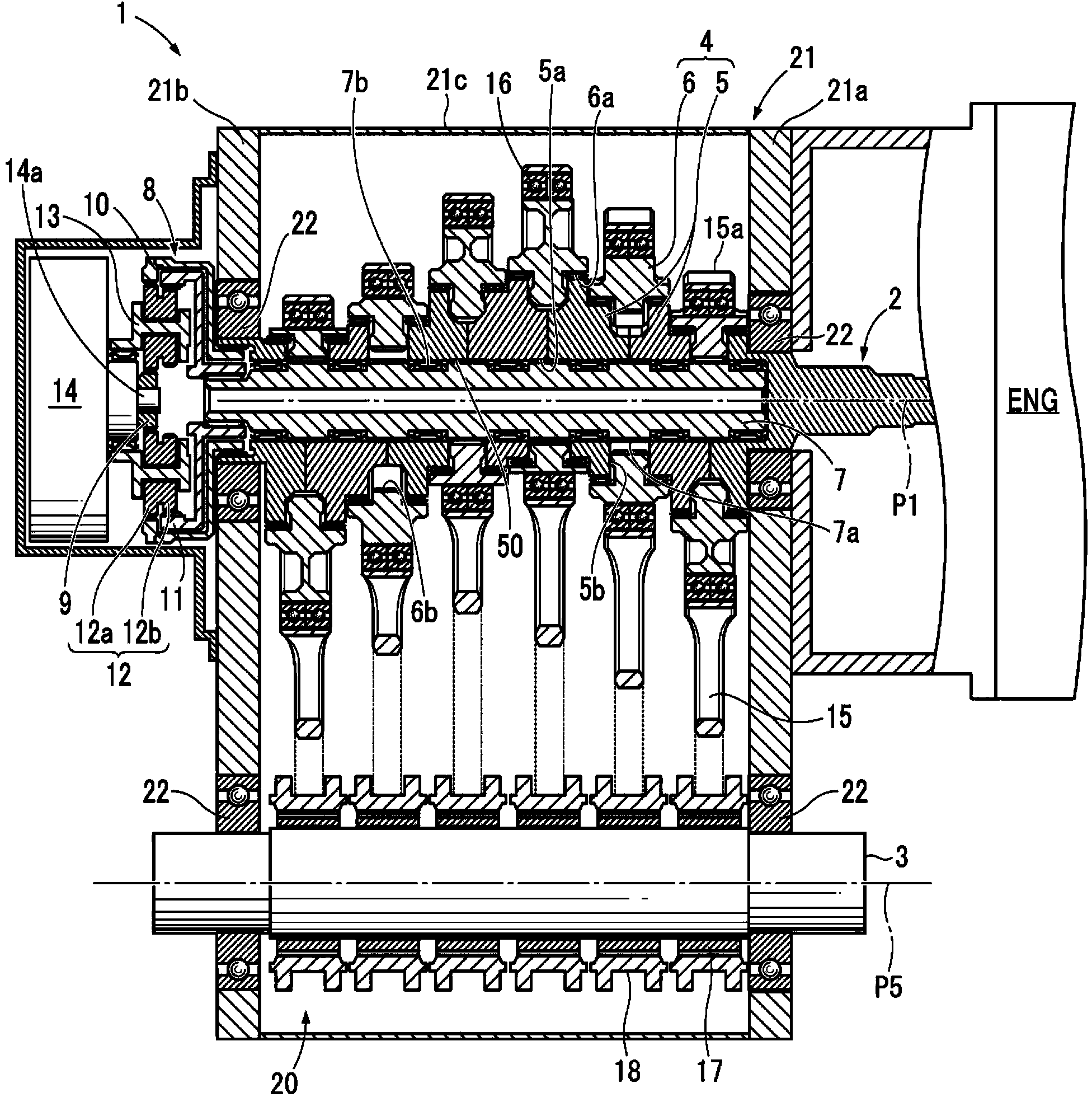

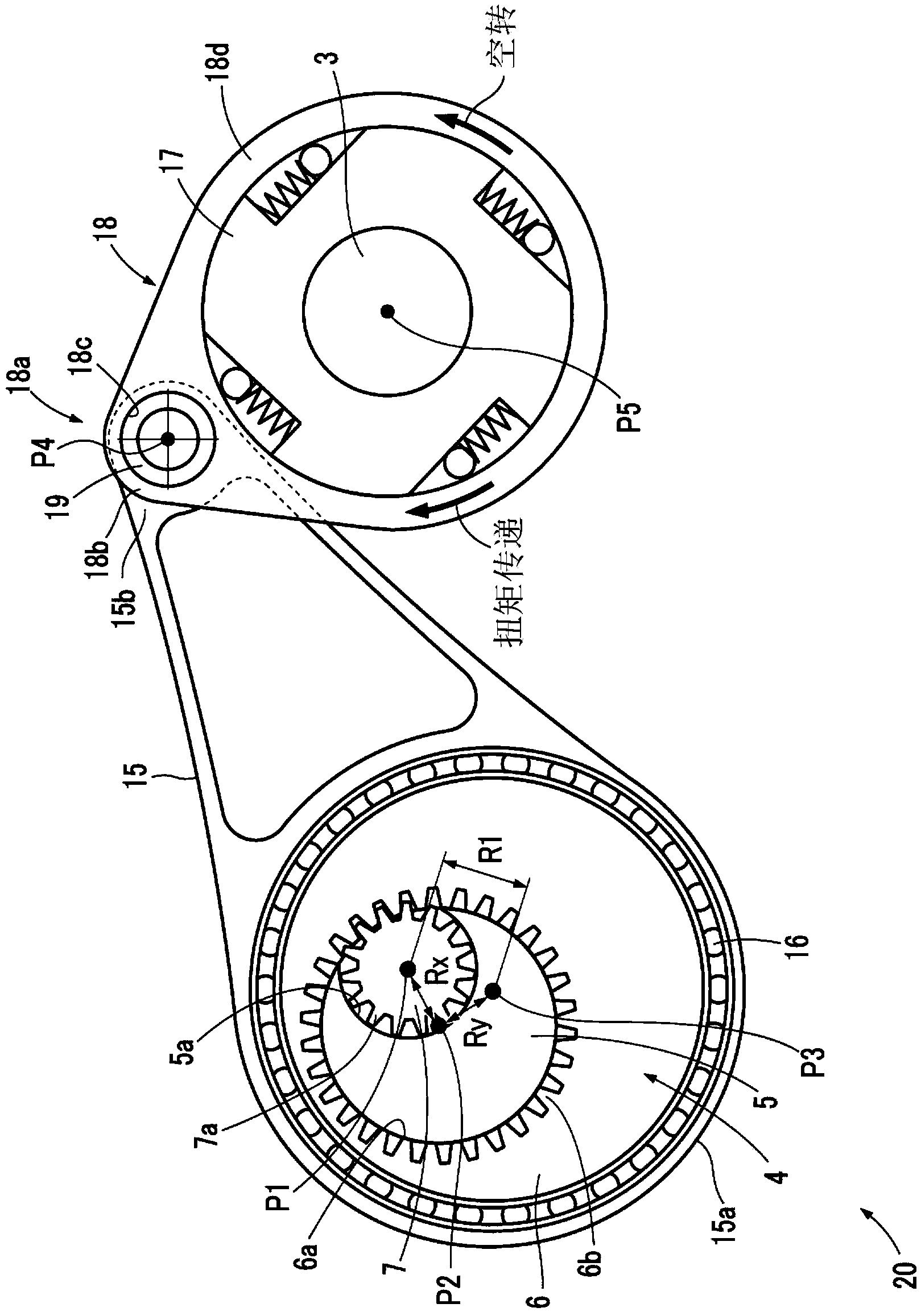

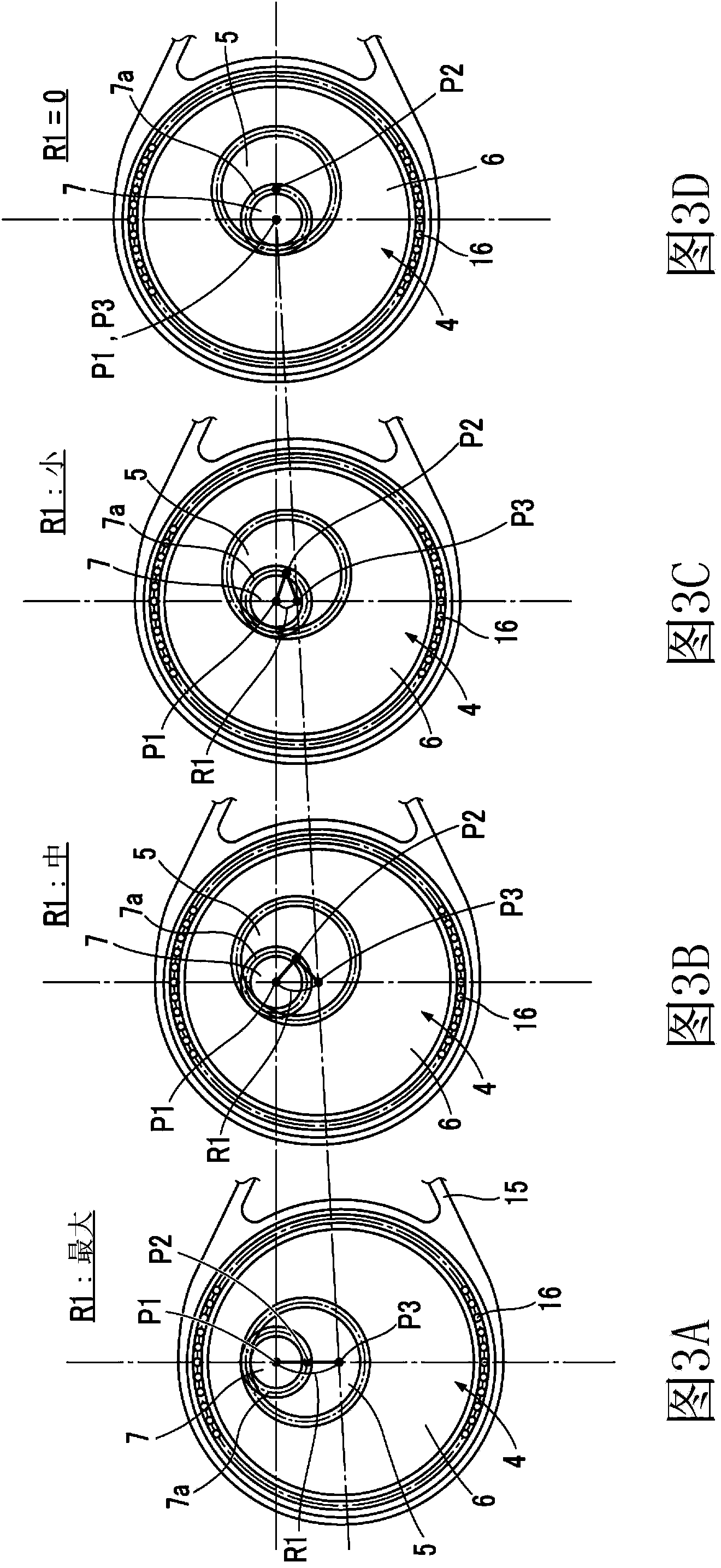

[0048] refer to Figure 1 to Figure 6 , the continuously variable transmission of the first embodiment will be described.

[0049] First, refer to figure 1 and figure 2 The structure of the continuously variable transmission 1 of this embodiment is demonstrated.

[0050] Such as figure 1 As shown, the continuously variable transmission 1 of the present embodiment includes: an input part 2; an output shaft 3 arranged parallel to the rotation center axis P1 of the input part 2; on the rotation center axis P1.

[0051] The input unit 2 is rotated around the rotation center axis P1 by being transmitted with a driving force from an engine ENG (travel driving source) as a main driving source. Furthermore, as the main drive source, an electric motor or the like may be used in addition to the internal combustion engine.

[0052] The output shaft 3 transmits rotational power to drive wheels (not shown) of the vehicle via a differential gear (not shown). Also, a propeller shaft ...

no. 2 Embodiment approach

[0119] refer to Figure 7A , 7B , the continuously variable transmission of this embodiment will be described. Wherein, the continuously variable transmission of the present embodiment differs from the continuously variable transmission of the first embodiment only in the swing link and the detected component, so only the swing link and the detected component will be described in detail. In addition, the same code|symbol is attached|subjected to the same structure as the continuously variable transmission of 1st Embodiment, and their description is abbreviate|omitted.

[0120] Such as Figure 7A , 7B As shown, the swing link 18 has a swing end portion 18 a connected to the link 15 and an annular portion 18 d pivotally supported by the output shaft 3 .

[0121] In addition, two attachment pins 25 are provided on the outer peripheral surface of the annular portion 18 d of the swing lever 18 , and the member to be detected 26 is slidably attached to the attachment pins 25 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com