A new type of shift fork for commercial vehicles

A commercial vehicle, a new type of technology, applied in instruments, controlled components, mechanical control devices, etc., can solve problems such as gears not in place, easy to wear forks, and wear and tear of forks, and achieve fast shifting response and smooth shifting. , the effect of reducing sliding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

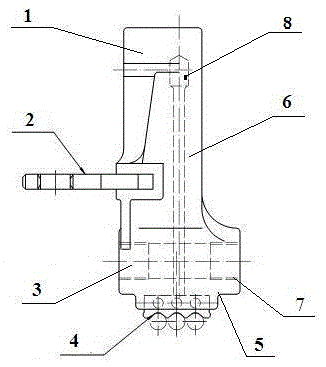

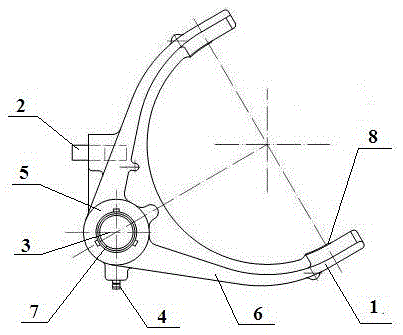

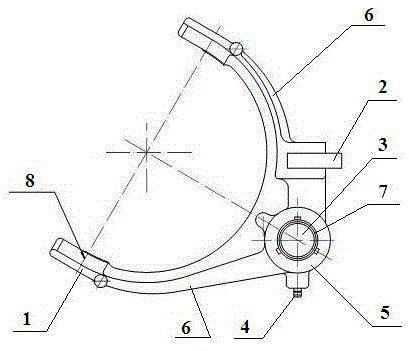

[0013] In the figure: a new type of shift fork for commercial vehicles, including a shift fork head 5, a shift fork body 6, and a shift fork foot 7. There is a shift fork shaft installation hole 3 on the shift fork head 5, and a pressure sleeve is provided in the shift fork shaft installation hole 3. That is, the shift fork hole pressure bushing 7 is a double alloy bush, one at each end, the inner layer of the shift fork hole pressure bush 7 is a wear-reducing plastic layer, and the installation of the shift fork hole pressure bush 7 adopts a hydraulic numerical control press. The sleeve is convenient to measure the interference force, and the contact seal is used to prevent the bushing 7 from falling off the hole of the shift fork. There is a pair of friction pairs 8 at the contact point between the shift fork and the tooth sleeve. The surface of the friction pair 8 is an arc-shaped structure; There are two clamps inlaid on the aluminum alloy base of the fork: one is the shift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com