Double-layer steel belt cooling device

A steel strip cooling and steel strip technology, applied in water shower coolers, heat exchange equipment, direct contact heat exchangers, etc., can solve problems such as cooling water overflow, prevent overflow, facilitate recooling, use Safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further illustrate the present invention, introduce below in conjunction with accompanying drawing of description:

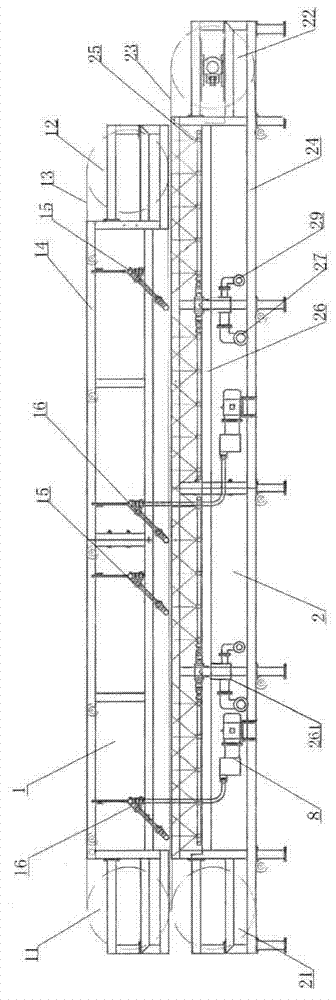

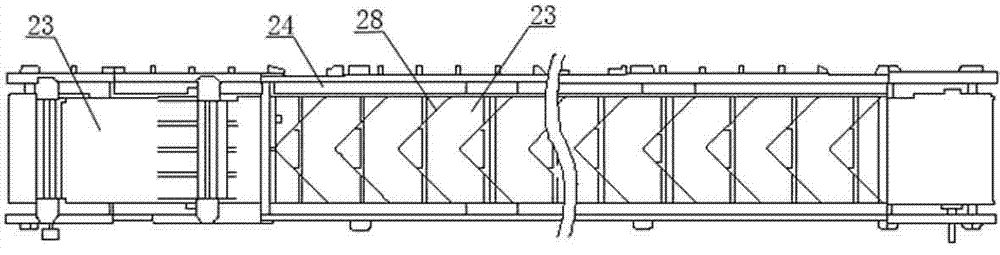

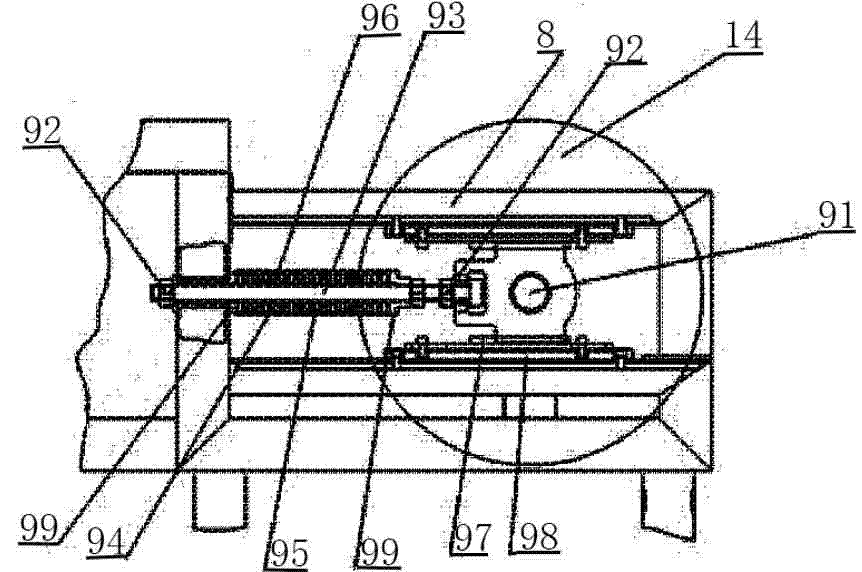

[0021] With reference to the accompanying drawings, the double-layer steel strip cooling device comprises an upper steel belt mechanism 1, a lower steel belt mechanism 2 and a cooling machine, the upper steel belt mechanism 1 is installed above the lower steel belt mechanism 2, and the upper steel belt mechanism 1 and the lower steel belt mechanism A material forming passage is formed between the belt mechanisms 2, the lower steel belt mechanism 2 is longer than the upper steel belt mechanism 1, and the position where it grows out is the feed inlet, and the upper steel belt mechanism 1 includes a left upper roller 11, a right upper roller 12, and an upper steel belt mechanism. Belt 13, cuboid frame 14, water inlet 15 and water intake 16, left upper roller 11 and right upper roller 12 are contained in respectively by support frame 8 cuboid frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com