Transformer oil gassing device

A technology for transformer oil and gas evolution, applied in the field of electric power engineering, can solve the problems of high equipment cost and unfavorable wide-scale popularization and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

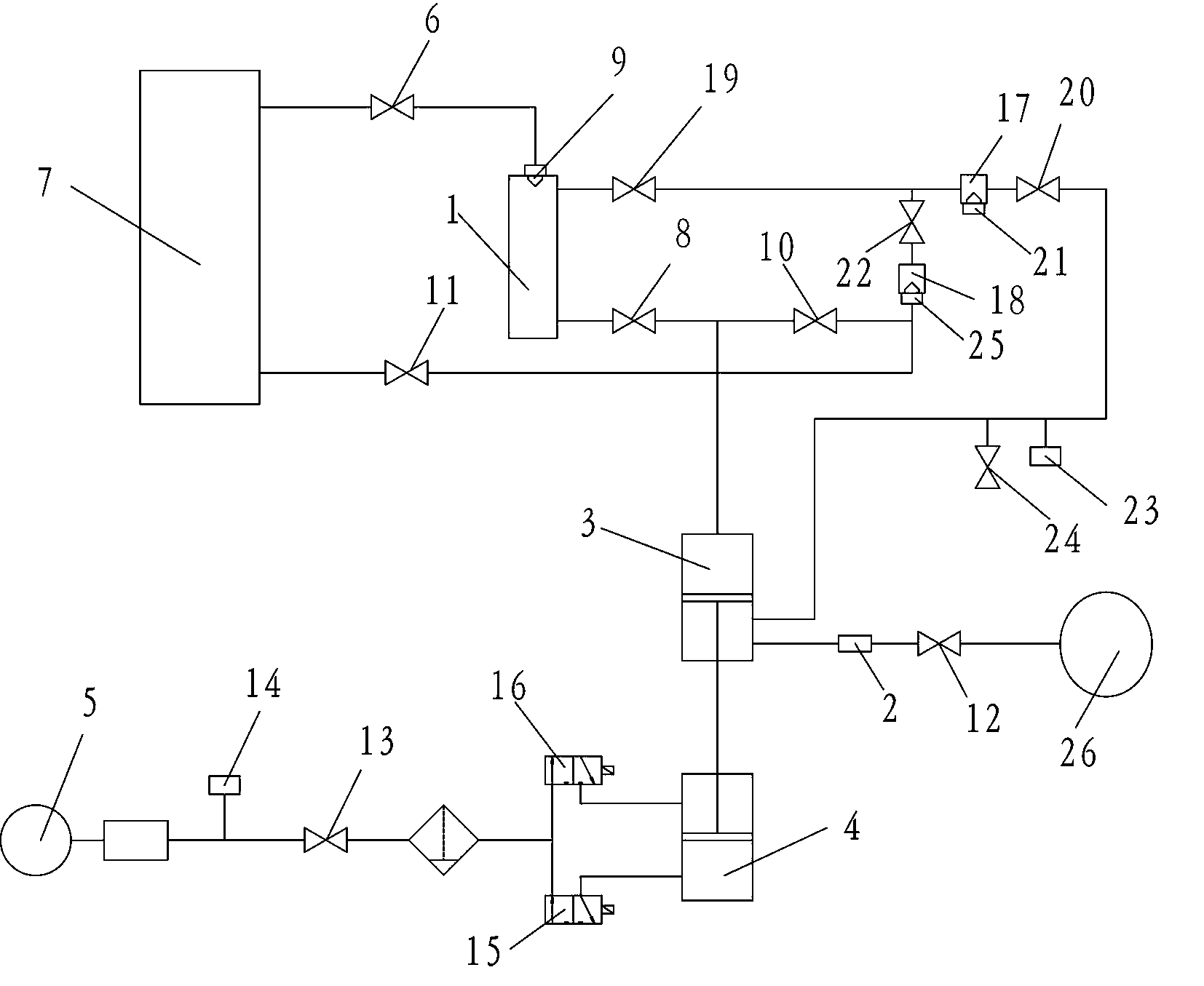

[0010] See attached picture. This embodiment includes a sampler 1, a quantitative tube 2, a vacuum chamber 3, a pneumatic chamber 4 and a compressor 5. The upper end of the sampler 1 is connected to the transformer 7 through an oil inlet valve 6, and the lower end of the sampler 1 is connected through a degassing communication valve 8. Connected to the upper end of the vacuum chamber 3, the sampler 1 has a first liquid level sensor 9; the upper end of the vacuum chamber 3 is also connected to the transformer 7 through the cylinder valve 10 and the oil discharge valve 11, and the lower end of the vacuum chamber 3 is connected to the pneumatic valve through the piston rod. The chamber 4 is matched; the outer end of the quantitative tube 2 is connected with the carrier gas valve 12, and the inner end is connected with the vacuum chamber 3; this embodiment also includes a certain gas valve 13 and a pressure controller 14; the pressure controller 14 is connected to the air outlet o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com