Method for simultaneously displaying bearing steel austenite grain boundary and transgranular martensite

A technique for simultaneous display of austenite grain boundaries, applied in the field of metallographic preparation, can solve the problems of difficult and cumbersome erosion operations of austenite grain boundaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

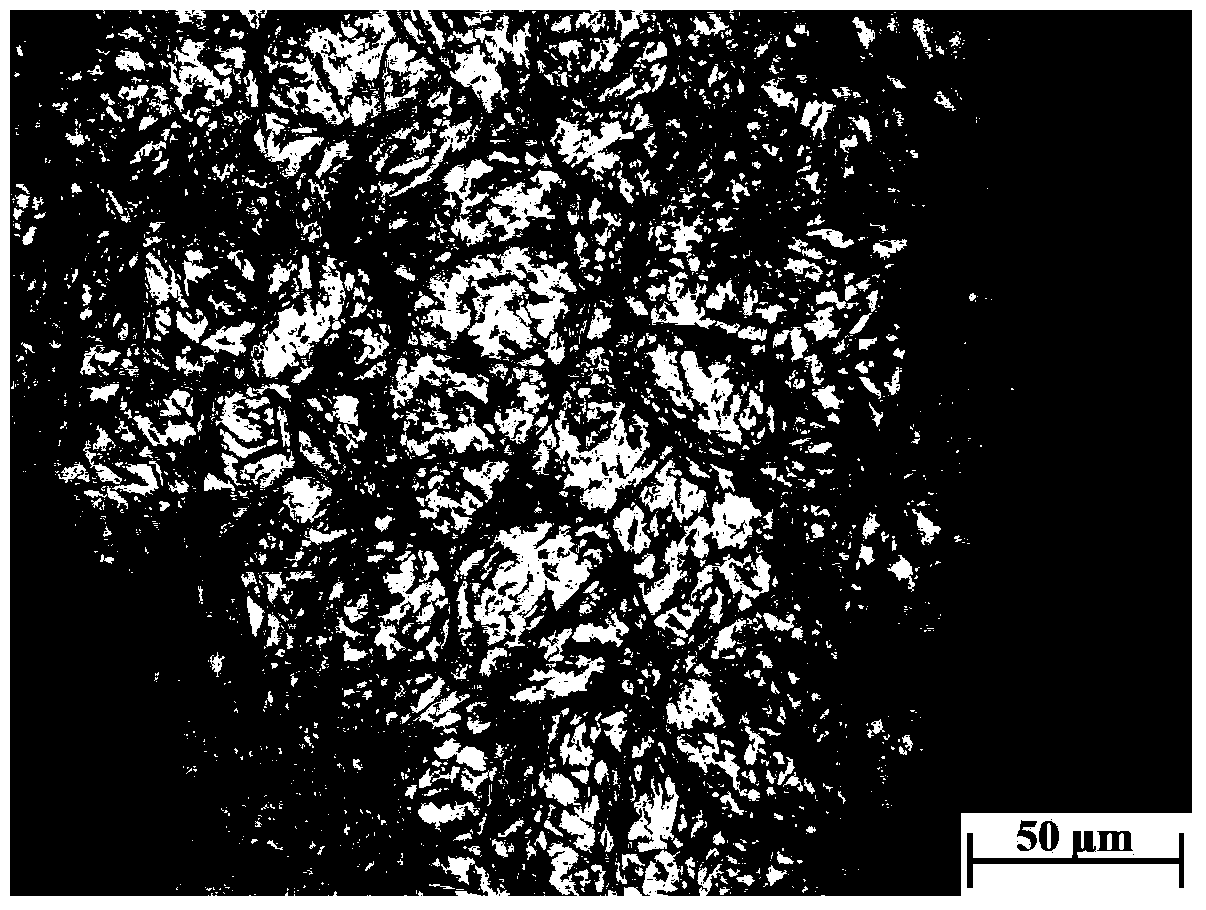

[0021] The GCr15SiMn steel rolling material with pearlite form is selected as the sample. The chemical composition of the GCr15SiMn steel is: C: 1.02%, Si: 0.55%, Mn: 1.07%, Cr: 1.49%, and the treatment method includes the following steps:

[0022] 1. Cut a 10mm×10mm×10mm block sample, set the heating temperature of the grain growth experiment to 1000℃, keep it for 15min, then cool it to 690℃ at 0.5℃ / s, and then quench it.

[0023] 2. Cut the sample in the middle, at 240#, 400#, 600#, 800#, 1000#, 1200# (that is, the particle size is 240 mesh, 400 mesh, 600 mesh, 800 mesh, 1000 mesh, 1200 mesh) Coarse grinding on the metallographic sandpaper from coarse to fine. Before replacing the sandpaper, make sure that there is no scratch on the surface of the sample perpendicular to the polishing direction. When replacing the sandpaper, the sample is rotated at an angle of 90°, and finally polished with 1000# sandpaper. After rough grinding, the polished surface of the sample is water-mille...

Embodiment 2

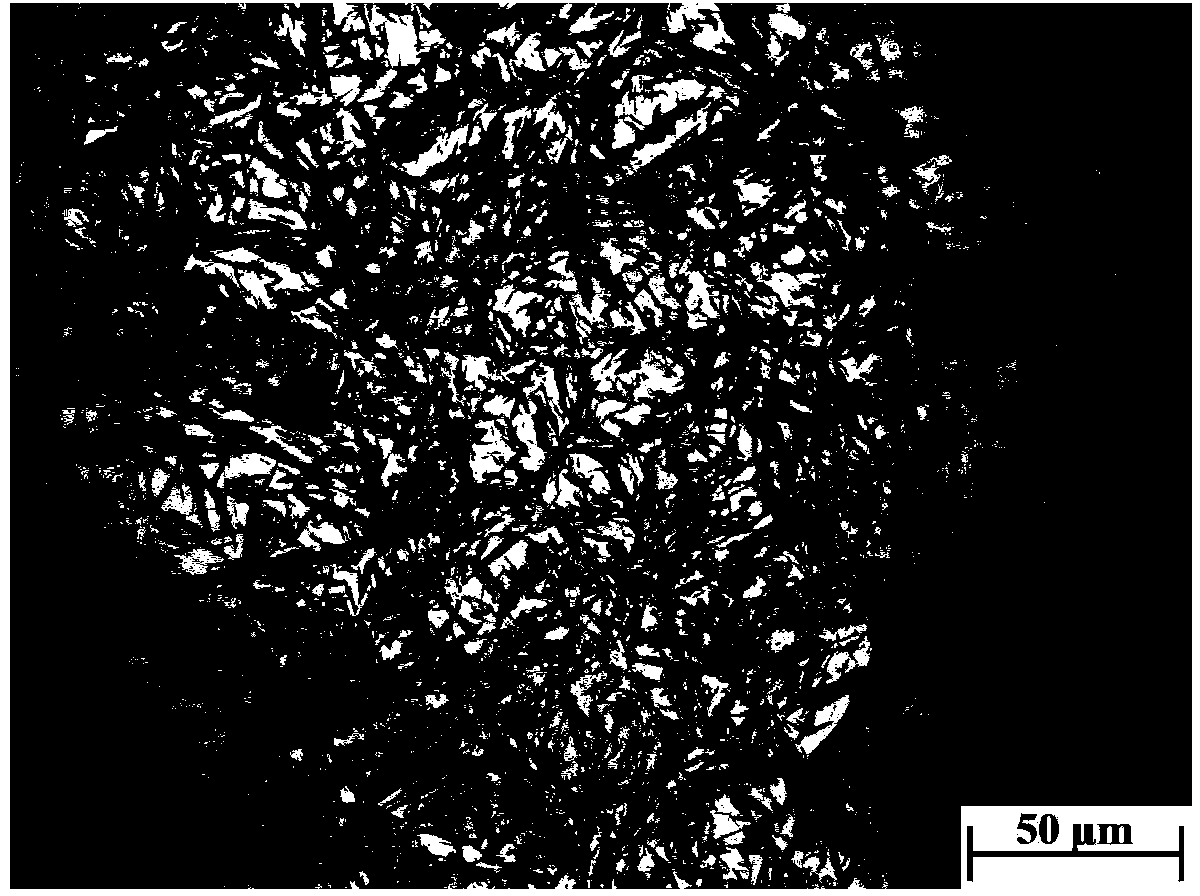

[0028] The GCr15SiMn steel rolling material with pearlite form is selected as the sample. The chemical composition of the GCr15SiMn steel is: C: 1.02%, Si: 0.55%, Mn: 1.07%, Cr: 1.49%, and the treatment method includes the following steps:

[0029] 1. Cut a 15mm×15mm×15mm block sample, set the heating temperature of the grain growth experiment to 1000℃, keep it for 15min, then cool it to 710℃ at 0.5℃ / s, and then quench it.

[0030] 2. Cut the sample in the middle, at 240#, 400#, 600#, 800#, 1000#, 1200# (that is, the particle size is 240 mesh, 400 mesh, 600 mesh, 800 mesh, 1000 mesh, 1200 mesh) Coarse grinding on the metallographic sandpaper from coarse to fine. Before replacing the sandpaper, make sure that there is no scratch on the surface of the sample perpendicular to the polishing direction. When replacing the sandpaper, the sample is rotated at an angle of 90°, and finally polished with 1000# sandpaper. After rough grinding, the polished surface of the sample is water-mille...

Embodiment 3

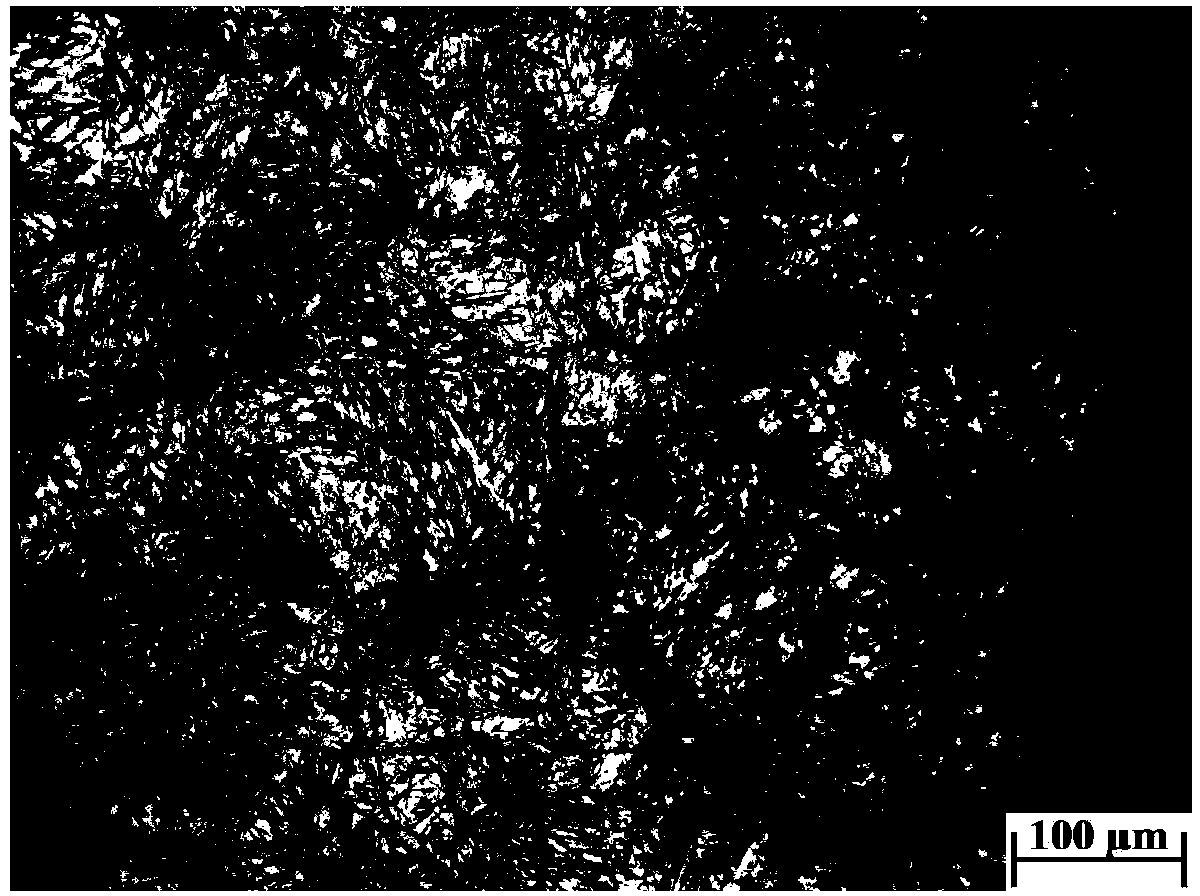

[0035] The GCr15SiMn steel rolling material with pearlite morphology is selected as the sample. The chemical composition of the GCr15SiMn steel is: C: 1.02%, Si: 0.55%, Mn: 1.07%, and Cr: 1.49%. The treatment method includes the following steps:

[0036] 1. Cut a 20mm×20mm×20mm block sample, set the heating temperature of the grain growth experiment to 1100℃, keep it for 15min, then cool it to 710℃ at 0.5℃ / s, and then quench it.

[0037] 2. Cut the sample in the middle, at 240#, 400#, 600#, 800#, 1000#, 1200# (that is, the particle size is 240 mesh, 400 mesh, 600 mesh, 800 mesh, 1000 mesh, 1200 mesh) Coarse grinding on metallographic sandpaper from coarse to fine. Before changing the sandpaper each time, ensure that there is no scratch on the surface of the sample perpendicular to the polishing direction. When replacing the sandpaper, the sample is rotated at an angle of 90°, and finally polished with 1000# sandpaper. After rough grinding, the polished surface of the sample is wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com