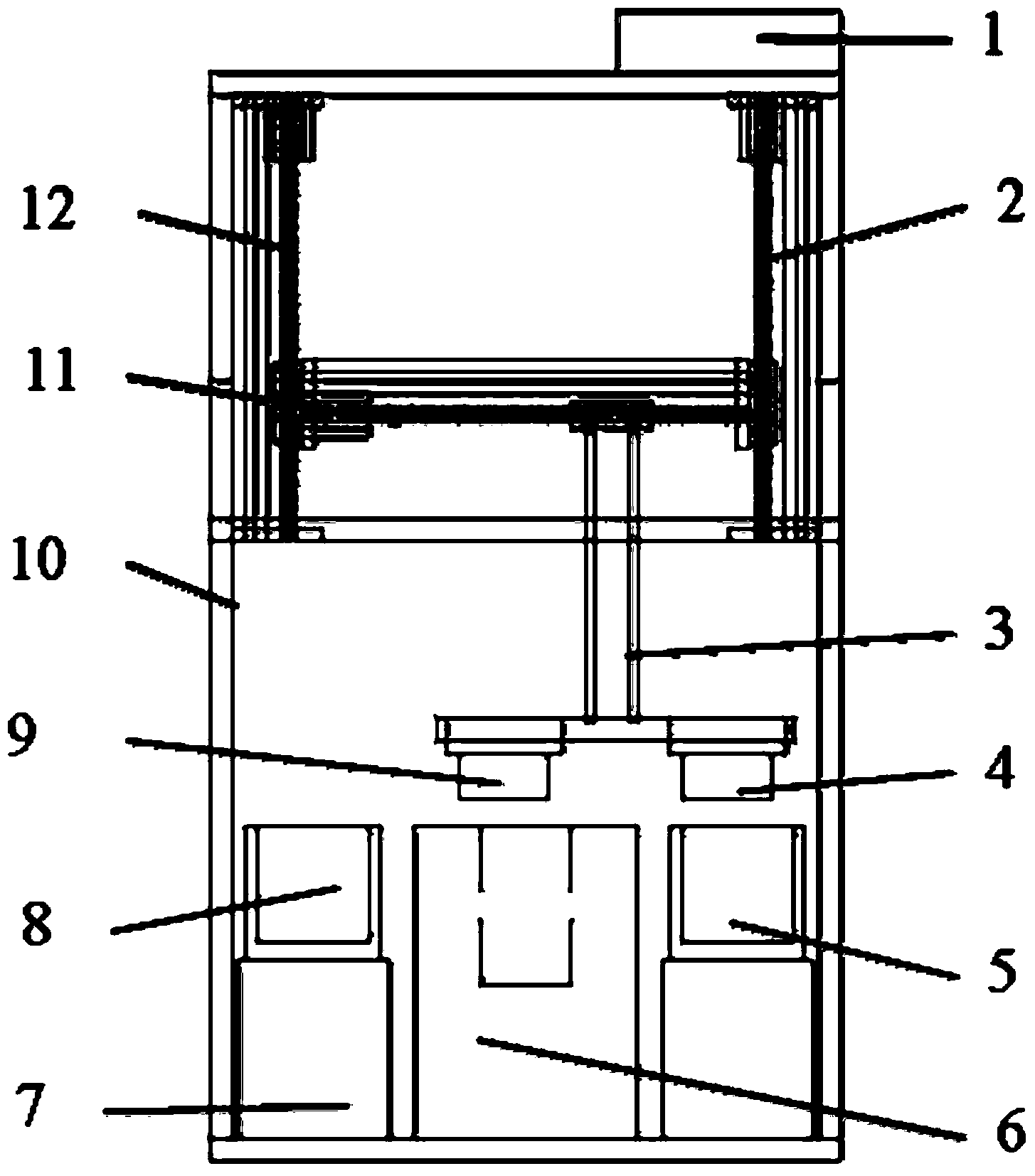

Automatic testing device for thermal shock property and thermal cycle oxidation property

A test device and thermal cycle technology, applied to measuring devices, mechanical devices, instruments, etc., can solve the problems of high energy consumption, energy waste, late night and early morning work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

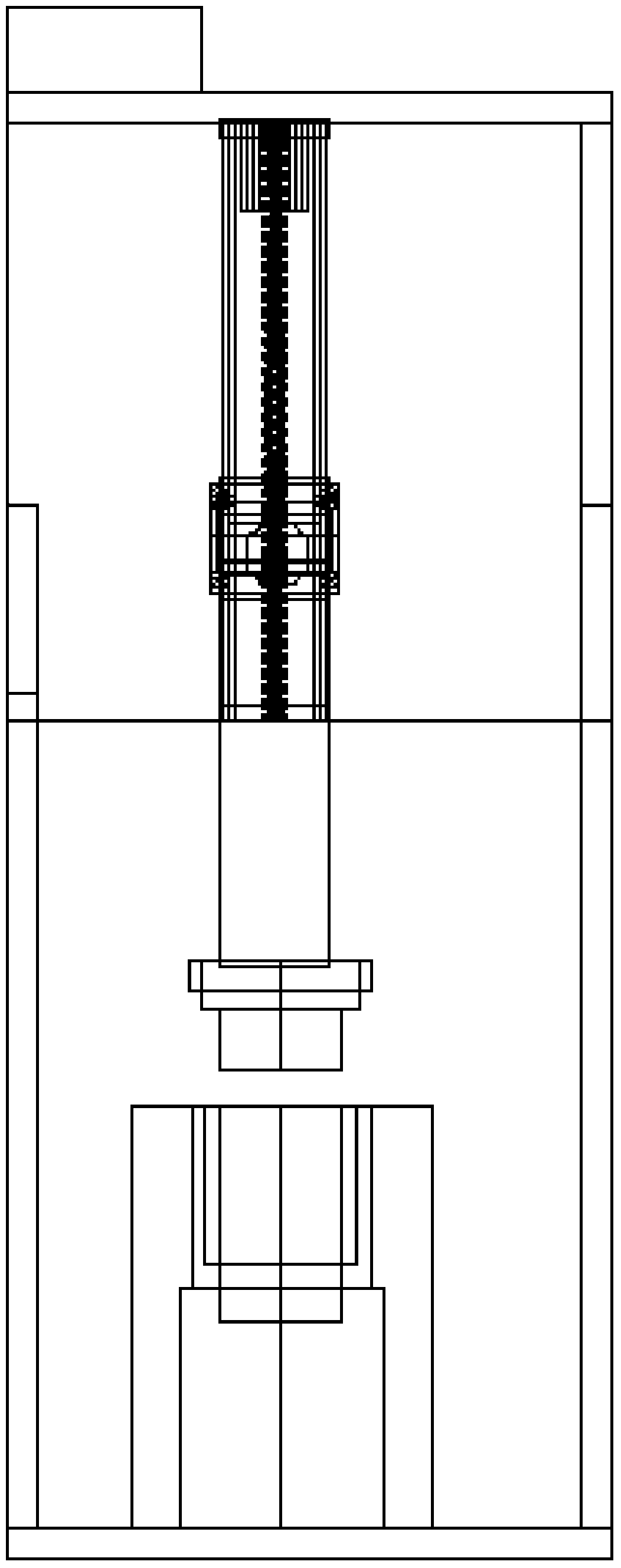

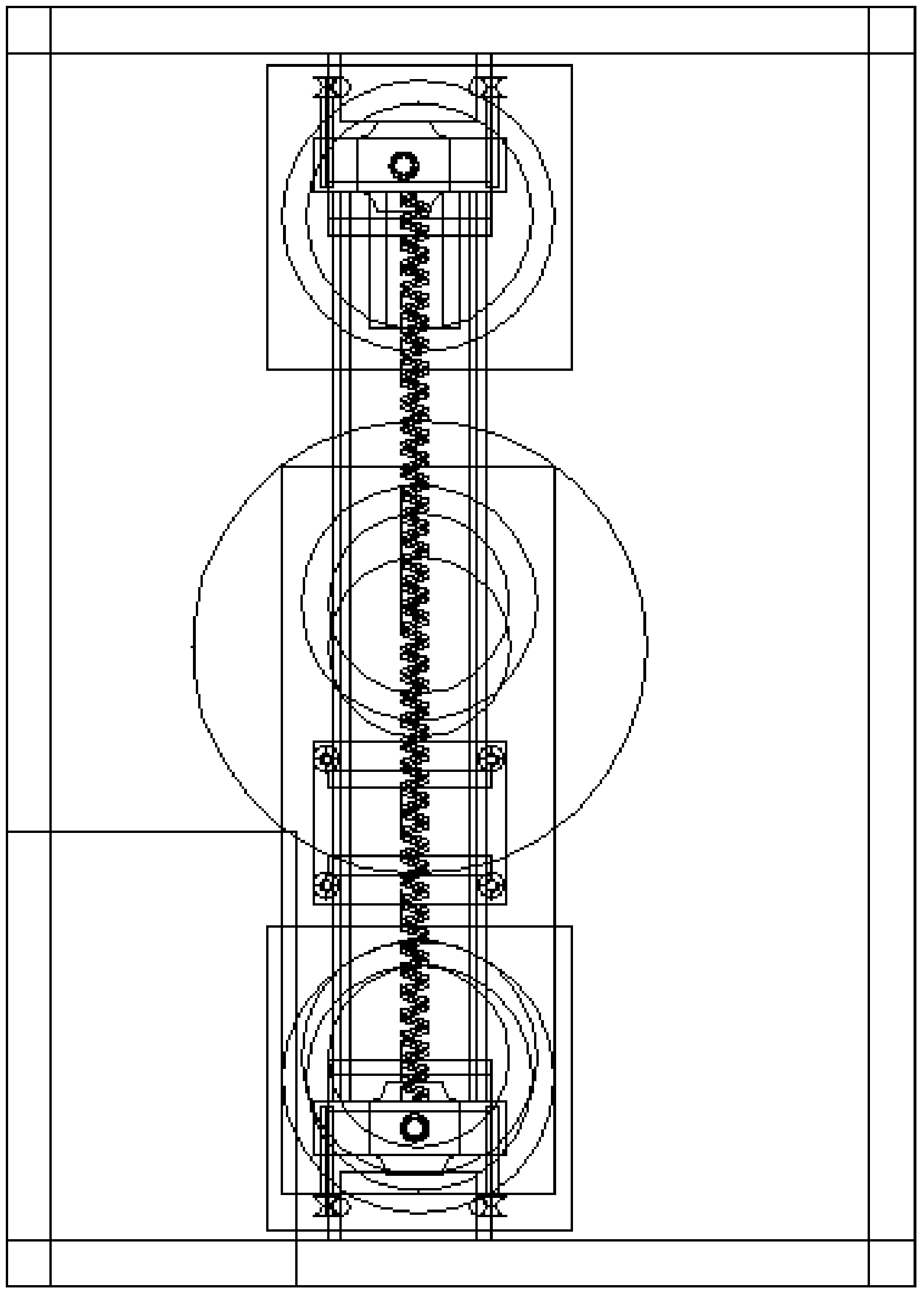

[0036] Embodiment 1 thermal shock test

[0037] In order to evaluate the thermal shock performance of TC4 titanium alloy micro-arc oxidation ceramic coating, the coating sample 1 with the surface of TC4 treated by micro-arc oxidation is suspended under the first furnace cover 4, and the second furnace cover 9 is buckled on the heating furnace. The furnace temperature was set at 800°C. After the temperature is constant, start the setting program, the first furnace cover 4 and the second furnace cover 9 quickly complete the alternation, the sample under the first furnace cover 4 is in a heating state, and the coated sample 2 after the same treatment is hung on the second furnace cover The second furnace cover is lowered 9 times. According to the program setting, after 10 minutes, the heating furnace cover is quickly alternated to realize the alternation of samples, and the alternate samples are placed in the first cooling medium holding container 5 equipped with cooling water f...

Embodiment 2

[0038] Embodiment 2 Thermal shock performance comparison test

[0039] In order to evaluate the thermal shock performance of thermal barrier coatings with two different thicknesses of superalloys, four samples were prepared, sample 1 and sample 2 as a group, sample 3 and sample 4 as a second group, and each group The two samples have the same thickness and are parallel samples. A group of two samples was suspended under the first furnace cover 4, and the temperature of the heating furnace was set at 1000°C. After the temperature is constant, start the setting program, the first furnace cover 4 and the second furnace cover 9 quickly complete the alternation, the samples under the first furnace cover 4 are in a heating state, and at the same time, the second group of thermal barrier coating samples with different thickness Piece 3 and sample piece 4 are suspended under the second furnace cover 9 . According to the program setting, after 10 minutes, the heating furnace cover is...

Embodiment 3

[0040] Embodiment 3 thermal cycle oxidation test

[0041] Suspend a weighed TC4 titanium alloy sample and a sample (TMAO) treated by micro-arc oxidation on the surface of TC4 under the first furnace cover 4, and buckle the second furnace cover 9 on the heating furnace, and heat The furnace temperature was set at 750°C. After the temperature is constant, start the setting program, the first furnace cover 4 and the second furnace cover 9 quickly complete the alternation, the sample under the first furnace cover 4 is in a heating state, and the second TC4 sample that has been weighed and The second TMAO sample is suspended under the second furnace cover 9 . After 10 hours, the equipment automatically completes the sample alternation. At this time, take off the two samples under the first furnace cover 4, weigh them and record them, and observe the surface morphology of the samples at the same time, then put the samples back and wait for the next time. Oxidation by heating. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com