Multi-standard automatic film advance adjustment device

An adjustment device and multi-specification technology, applied in the direction of using radiation for material analysis, etc., can solve the problems of less film specifications and low film digitization efficiency, and achieve the effects of meeting diverse needs, improving digitization efficiency, and improving accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

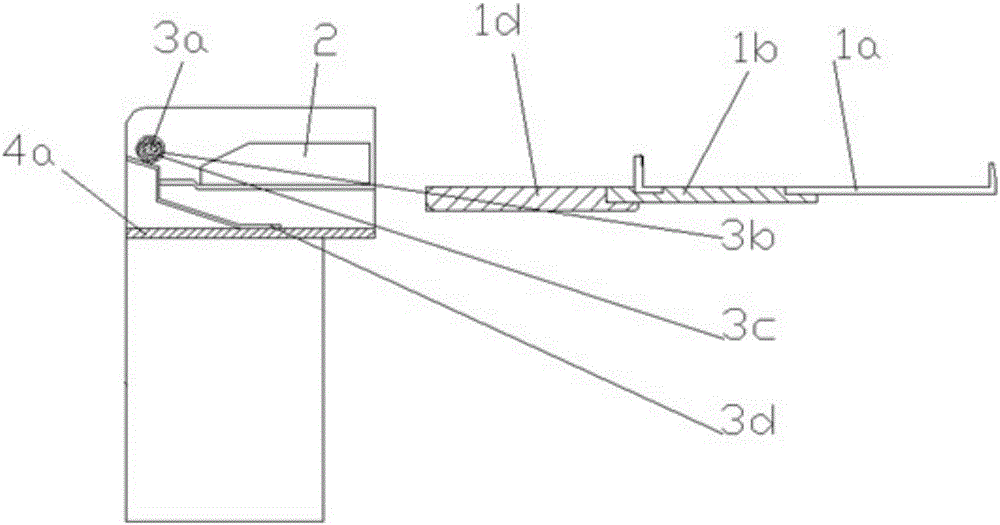

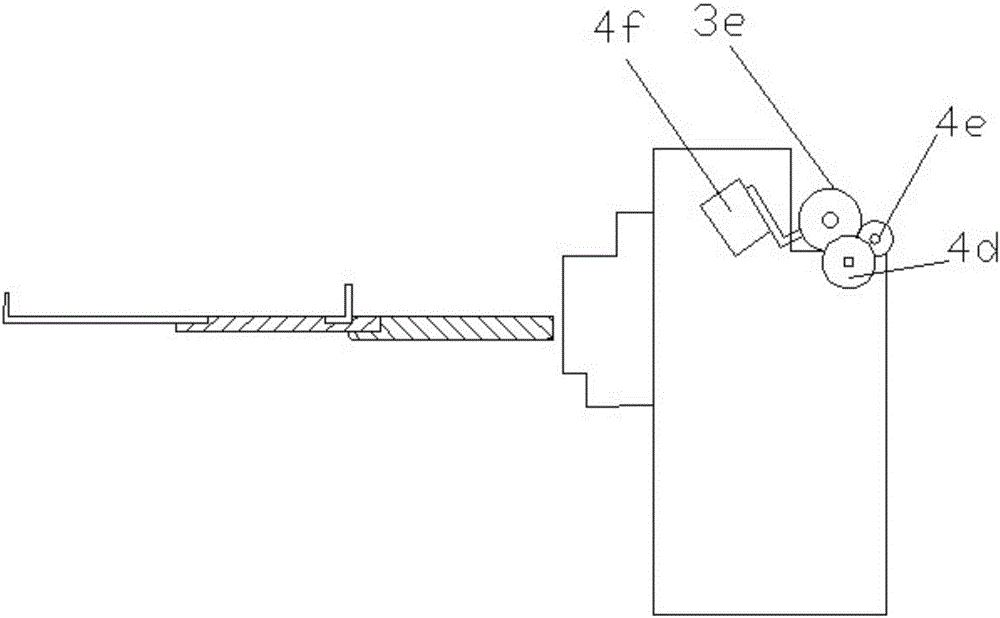

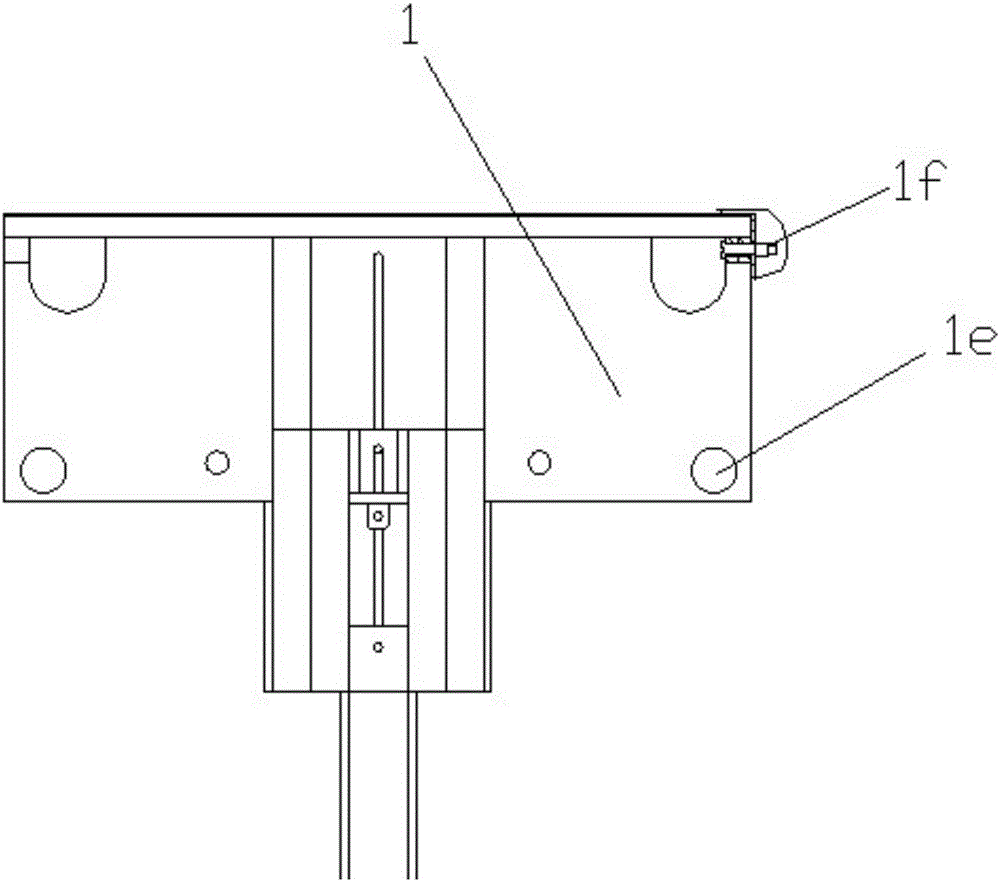

[0023] see Figure 1 to Figure 6 , a multi-standard automatic film feeding adjustment device of the present invention includes a housing, and a length adjustment device 1 arranged outside the housing. A film rubbing device 3, an automatic film feeding and film racking device 4 is arranged below the width adjusting device 2;

[0024] see figure 1 and image 3 The length adjusting device 1 includes a supporting plate 1d connected to the sheet feeding plate 2e, a secondary drawing plate 1b that can be extended is provided in the middle of the supporting plate 1d, and a primary drawing plate that can be extended is provided in the middle of the secondary drawing plate 1b. The pull plate 1a and the secondary pull plate 1b are vertically provided with baffles, the supporting plate 1d is provided with a magnet 1e, and a rotating shaft 1f is provided at the connection with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com