Full-automatic down feather filling power tester

A bulkiness and measuring instrument technology, applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of low degree of automation and low test accuracy, and achieve the effects of sensitive and reliable detection position, convenient operation and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate the understanding of the present invention, the specific implementation of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

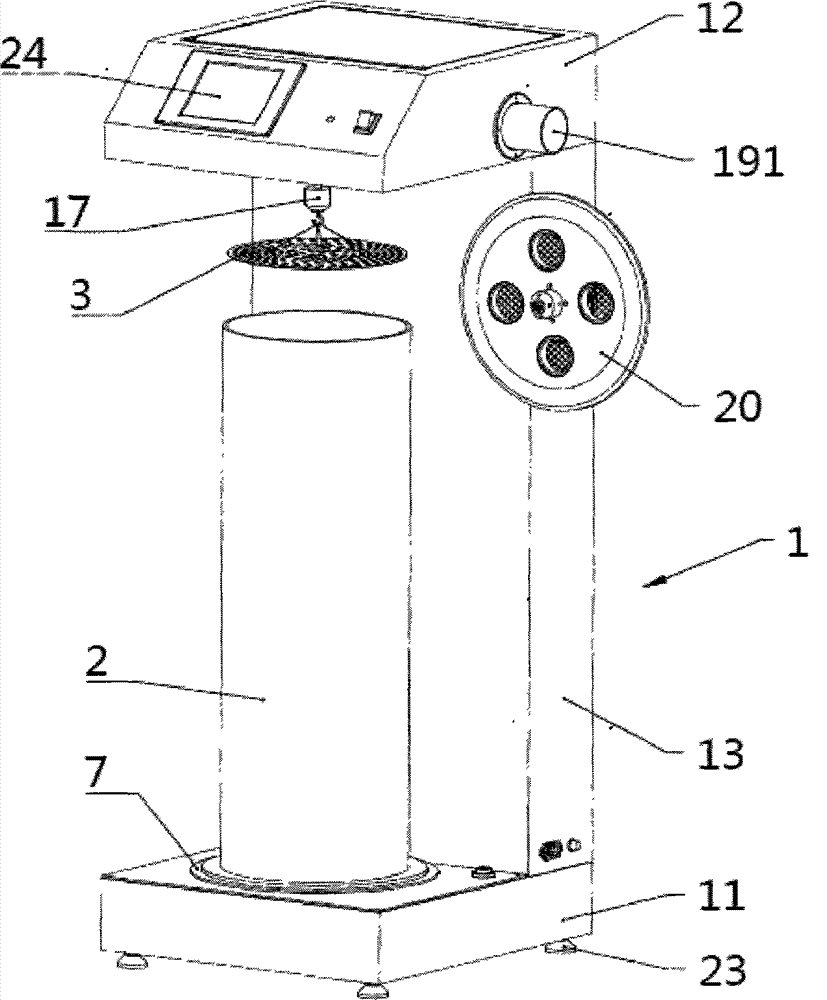

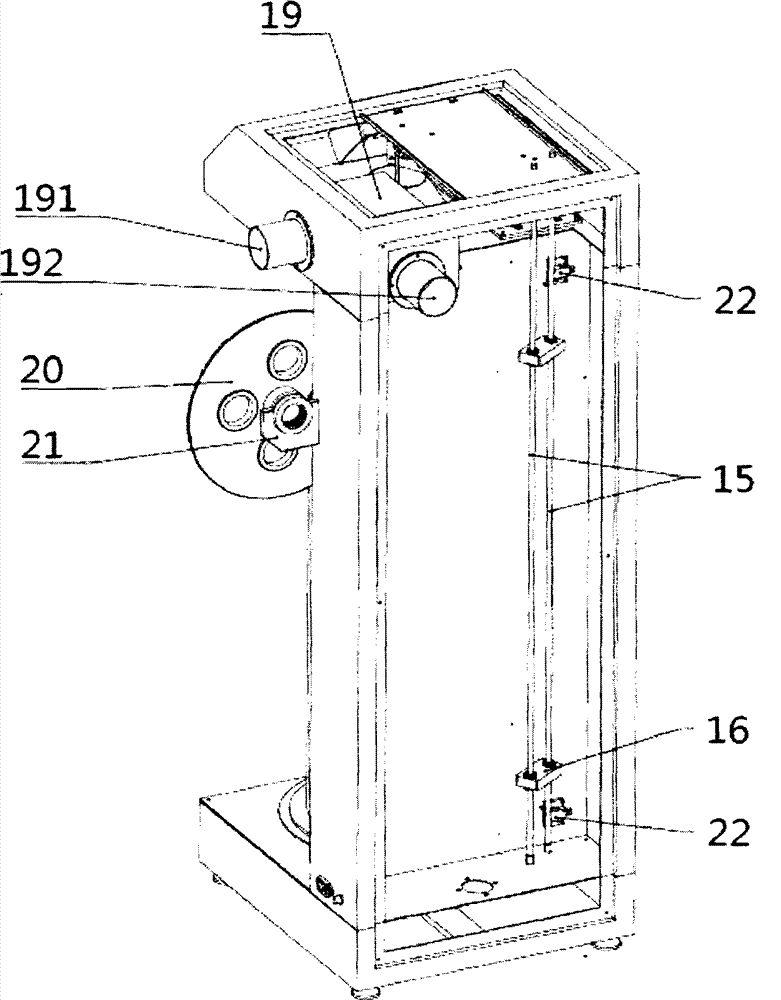

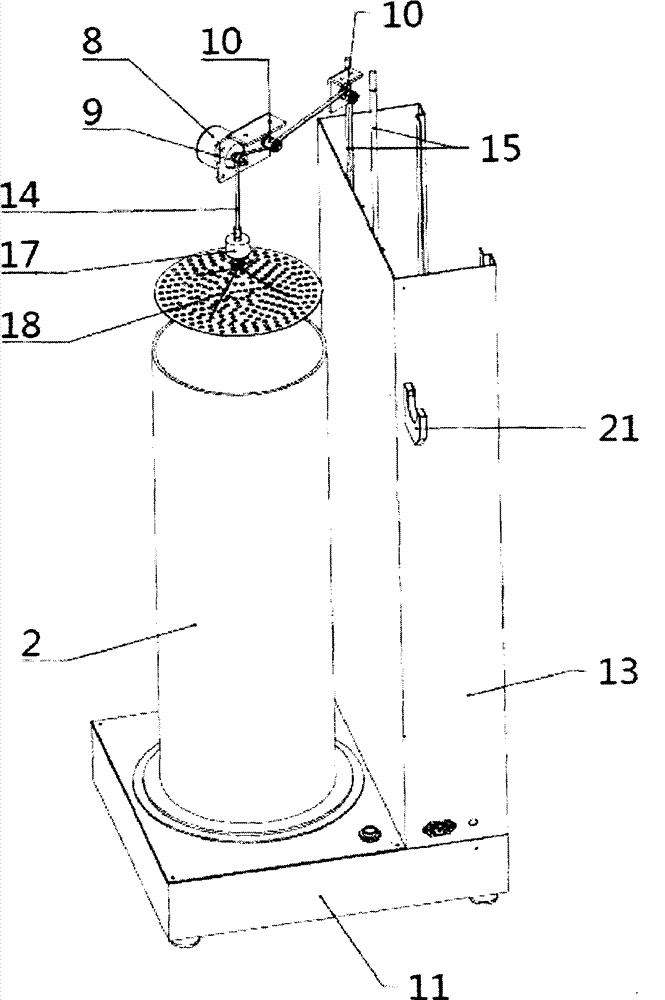

[0026] This example Figure 1-Figure 5 The shown full-automatic down and down bulkiness tester includes a frame 1. The frame 1 includes a bottom frame 11, a top frame 12 arranged above the bottom frame 11, and a supporting stand 13 connecting the two; The frame 11 is provided with a cylindrical test tube 2 with an opening facing upwards and a load cell 4 supporting the test tube 2; in the axial direction of the test tube 2, a circular sample pressure plate 3 capable of moving vertically up and down in the test tube 2 is provided. The frame 12 is provided with a stepping servo system that drives the sample pressing plate 3 to move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com