Checking device, checking device correcting method and checking method thereof

A technology for checking devices and correcting signals, applied in measuring devices, data processing input/output process, short-circuit test, etc., can solve the quality of scratch formation, instability of oxide film contact resistance, instability of electrodes and contact heads And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

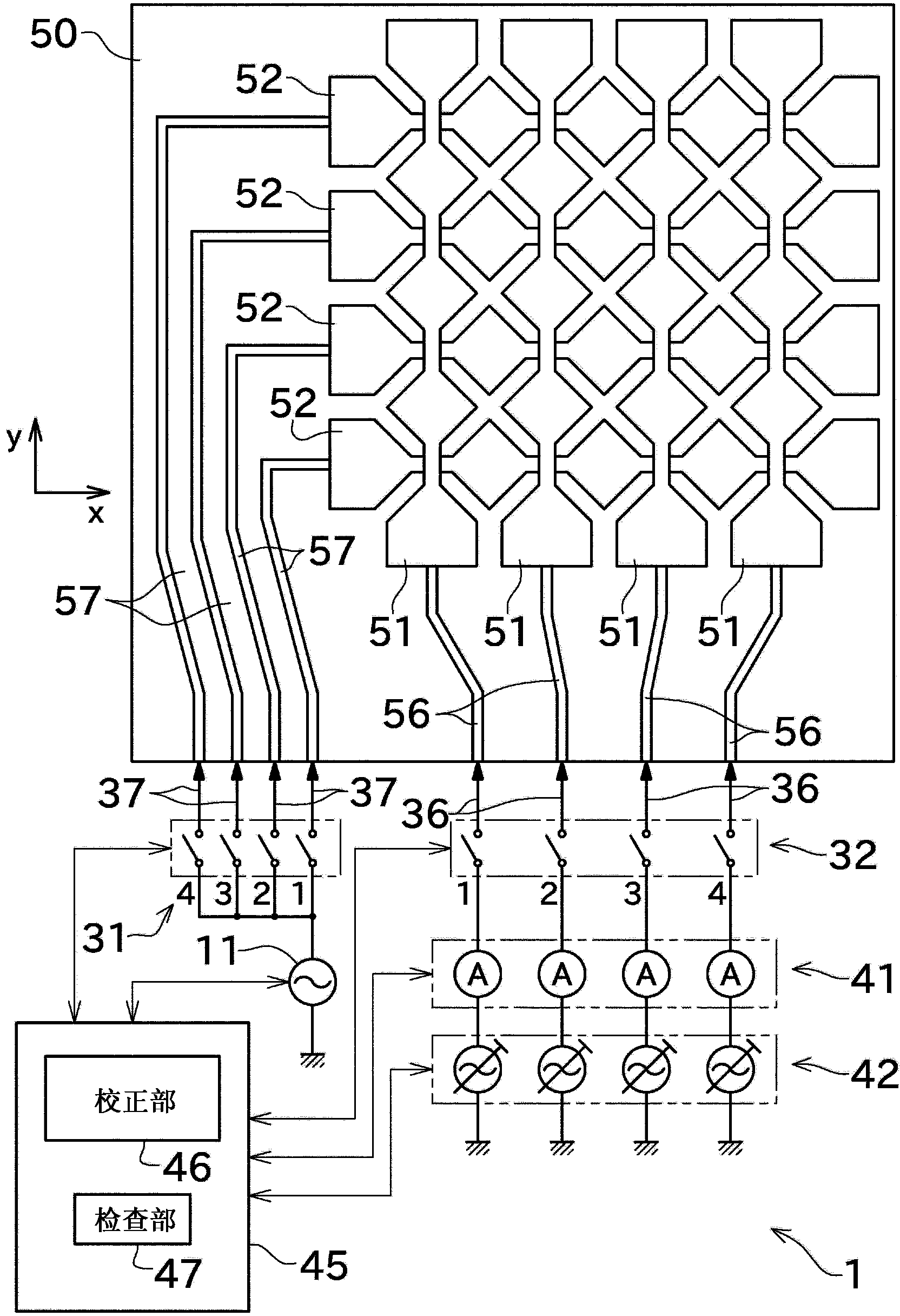

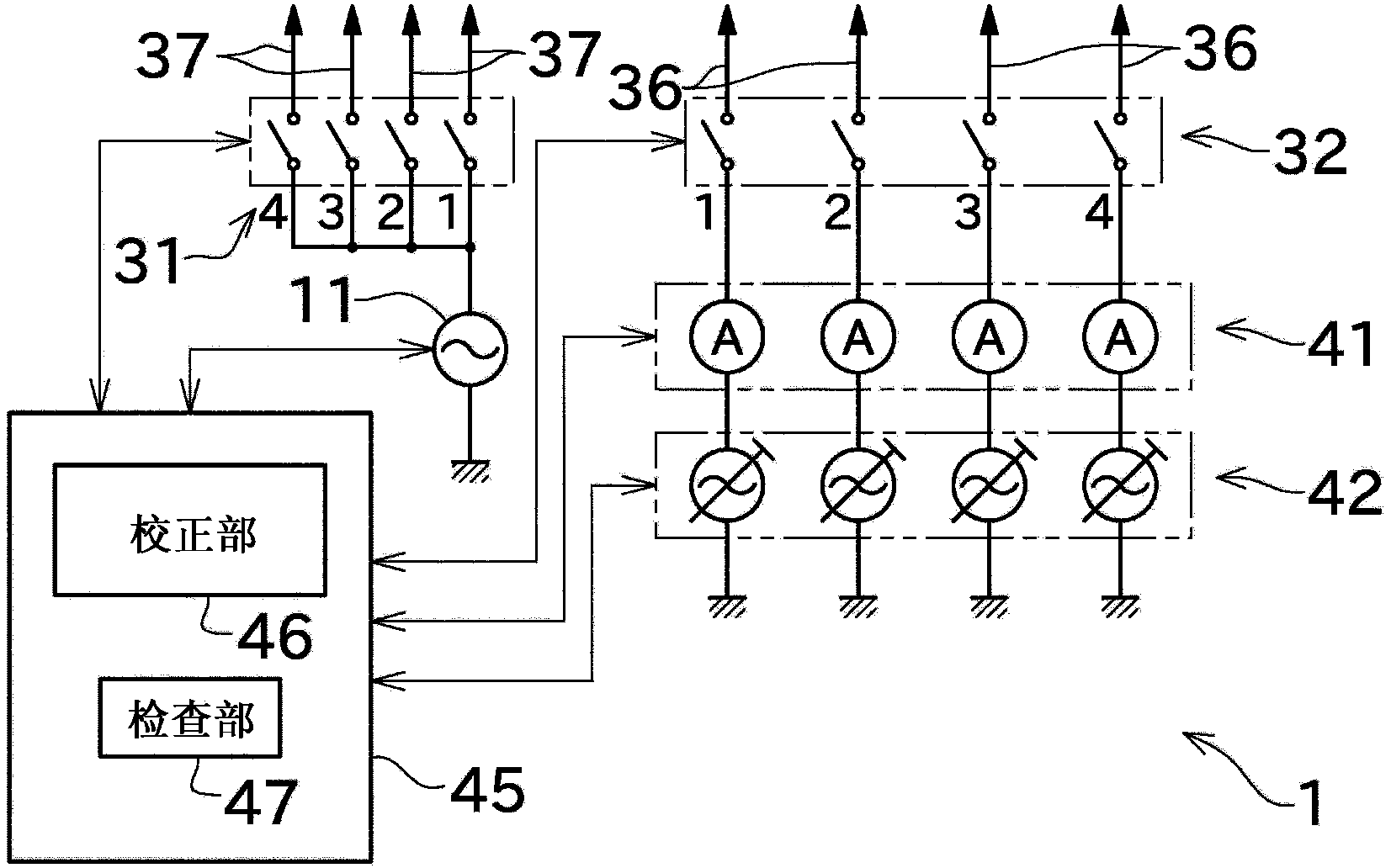

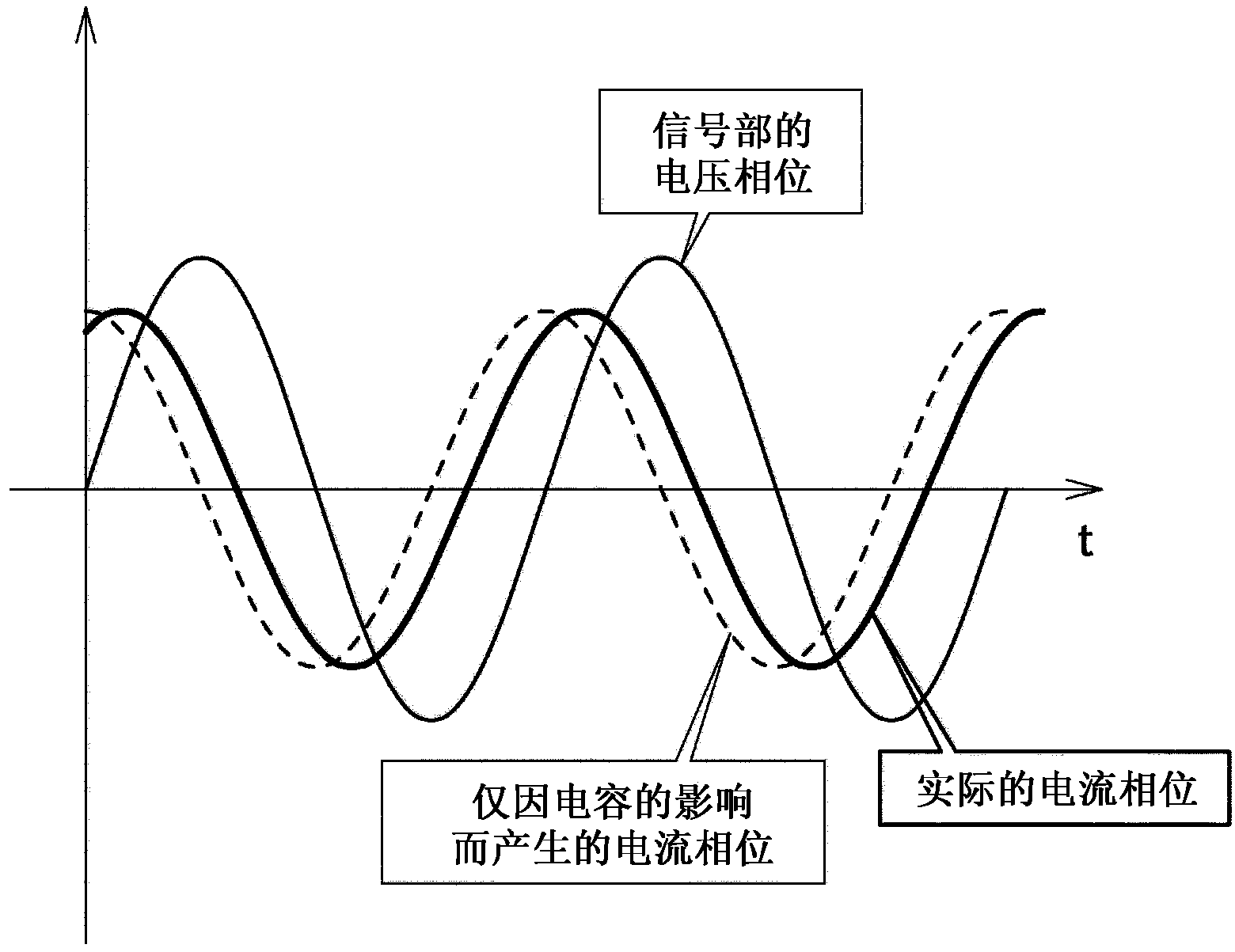

[0063] Next, embodiments of the present invention will be described with reference to the drawings. figure 1 It is a schematic diagram which shows the whole structure of the sensor panel inspection apparatus 1 which concerns on one Embodiment of this invention. figure 2 It is a figure which shows the state which performed the calibration of the sensor panel inspection apparatus 1 in the state which removed the sensor panel. image 3 It is a graph showing the relationship between the voltage phase of the signal unit 11 and the current phase detected by the ammeter of the current detection unit 41 .

[0064] figure 1 The shown sensor panel inspection device 1 is configured to inspect a sensor panel 50 as an inspection object. figure 1 A state in which the sensor panel 50 is installed on the sensor panel inspection device 1 is shown.

[0065] The sensor panel 50 is a main component of the touch panel device, and is composed of a plurality of first electrodes (first conductors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com