Transmission mechanism and transmission method for connecting rod of extra-high voltage circuit breaker

A technology of connecting rod transmission and circuit breaker, applied in the direction of protection switch operation/release mechanism, etc., can solve the problems of high proportion of mechanical failure, unstable movement of transmission mechanism, electrical system failure, etc., achieving light weight, small space, The effect of preventing stagnation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

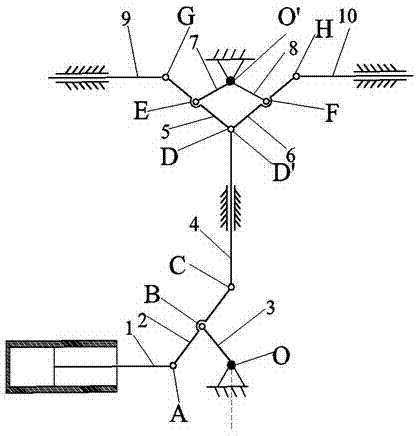

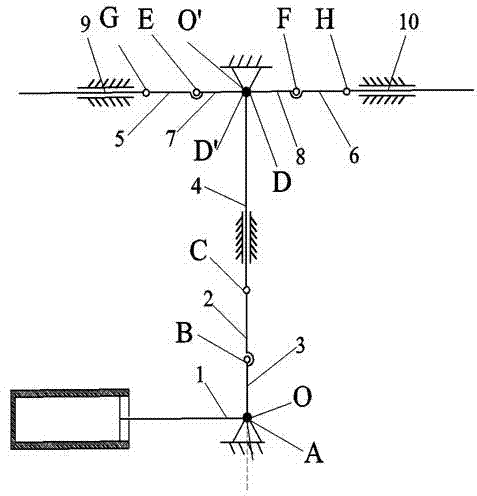

[0021] refer to figure 1 , 2 As shown: the present invention provides a UHV circuit breaker linkage transmission mechanism, including a joint 1, a lower linkage 2, a lower rocker 3, a sealing rod 4, a first upper linkage 5, a first upper linkage 6, The second upper rocker 7 , the second upper rocker 8 , the first moving contact rod 9 , and the second moving contact rod 10 .

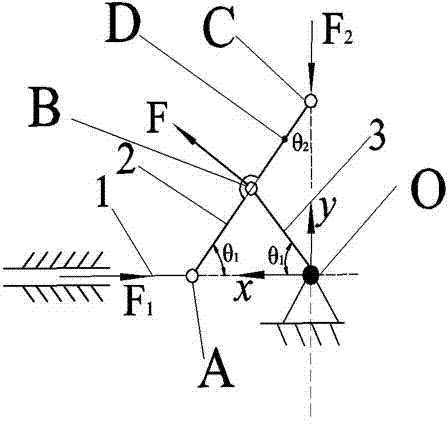

[0022] It is characterized in that it adopts the form of double fractures, and the sealing rod 4 and above components have a certain symmetry; the sealing rod and above to the moving contact are located in the arc extinguishing chamber of the extra-high circuit breaker. The rear end of the joint 1 is directly connected to the hydraulic cylinder of the hydraulic system, the front end of the joint 1 is hinged to the rear end of the lower link 2 on the hinge axis A, and the middle end of the lower link 2 is hinged to the OB end of the lower rocker 3 Axis B; the lower rocker 3 is hinged at the set position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com