Enhancement heat conduction structure for high-power CCD of space optical remote sensor

A technology of space optical remote sensing and thermal conduction structure, applied in electric solid devices, semiconductor devices, semiconductor/solid device components and other directions, can solve the problems of limited thermal conduction path, large contact thermal resistance, low thermal conduction efficiency, etc., to increase the contact area, improving thermal conductivity, and the effect of large heat dissipation channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

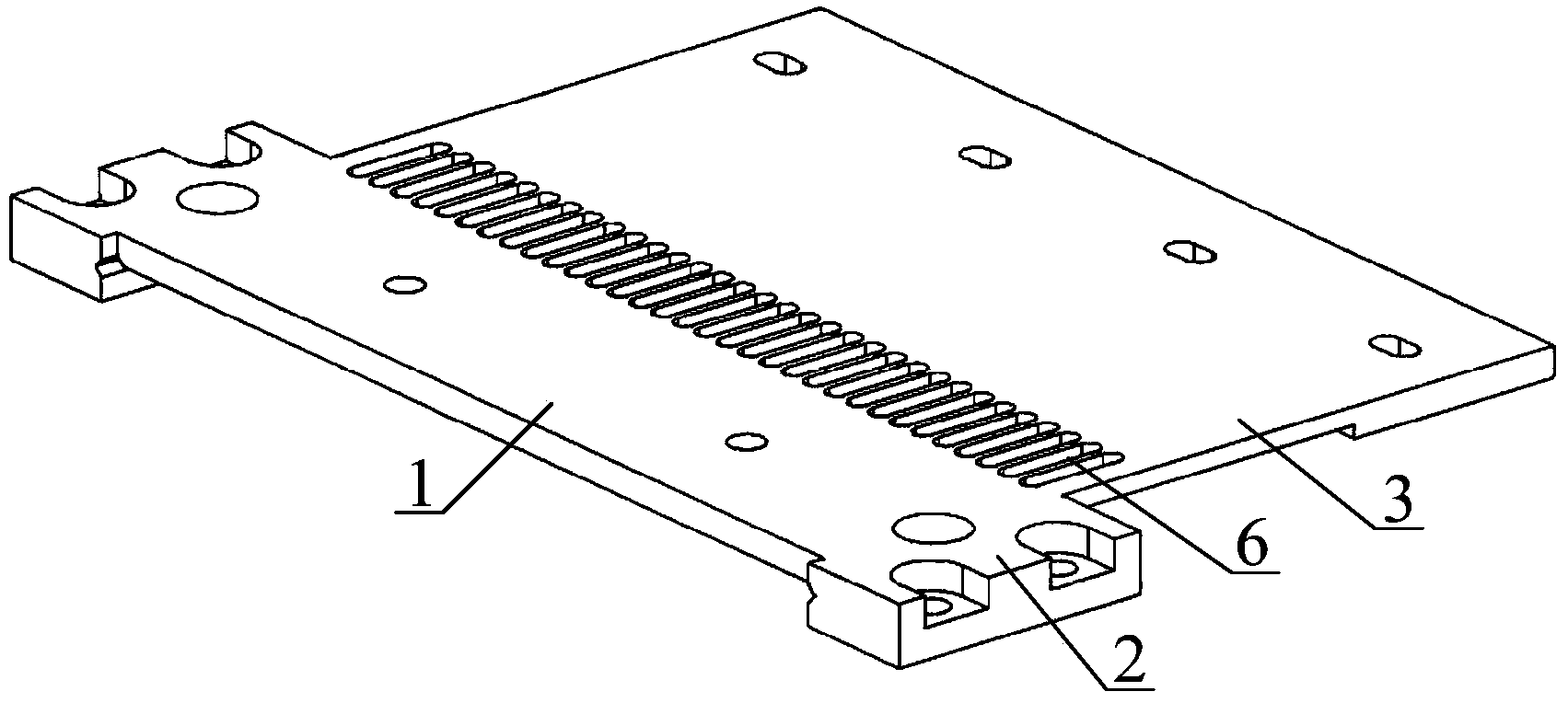

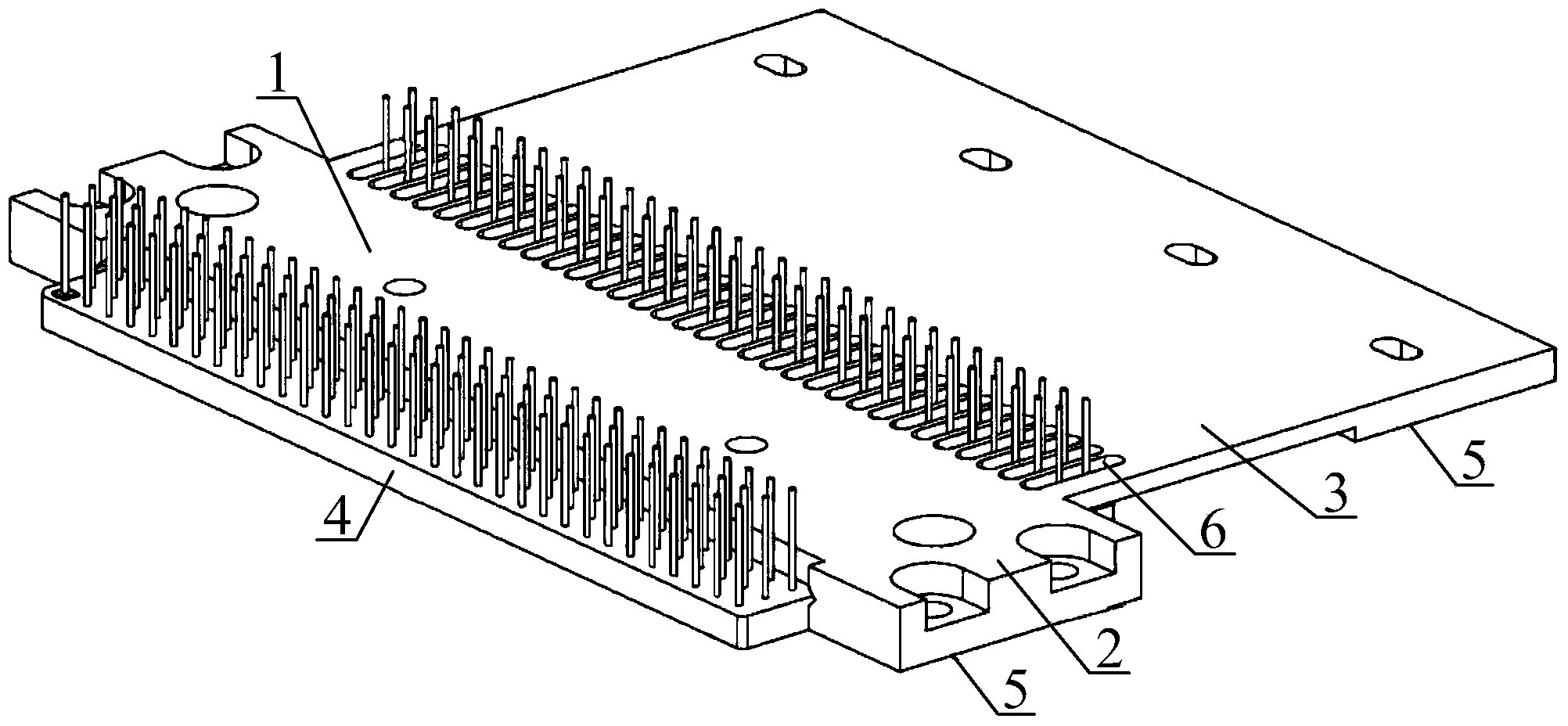

[0015] See attached figure 1 , the space optical remote sensor high-power CCD synergistic heat conduction structure of the present invention is a single integral component composed of a device press plate 1, a fixed end 2 and a synergistic heat conduction end 3; the fixed end 2 is located at both ends of the device press plate 1, so A plurality of slots 6 are evenly processed between the synergistic heat-conducting end 3 and the device pressing plate 1 , and the slots 6 correspond to the device pins on the back of the CCD device 4 one by one.

[0016] The distance between the side wall of the slot 6 and the device pin is the minimum safe distance of the device pin, that is, the width of the slot 6 is as small as possible on the basis of ensuring a safe distance from the device pin.

[0017] The material of the synergistic heat conduction structure is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com