Control circuit of alternating current-to-direct current converter

A technology of control circuit and DC power supply, which is applied in the direction of circuits, electric solid-state devices, and output power conversion devices. Simplify circuit layout, reduce hardware complexity, and improve yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention will be described below with reference to the accompanying drawings. In these drawings, the same reference numerals indicate the same or similar elements or method flows.

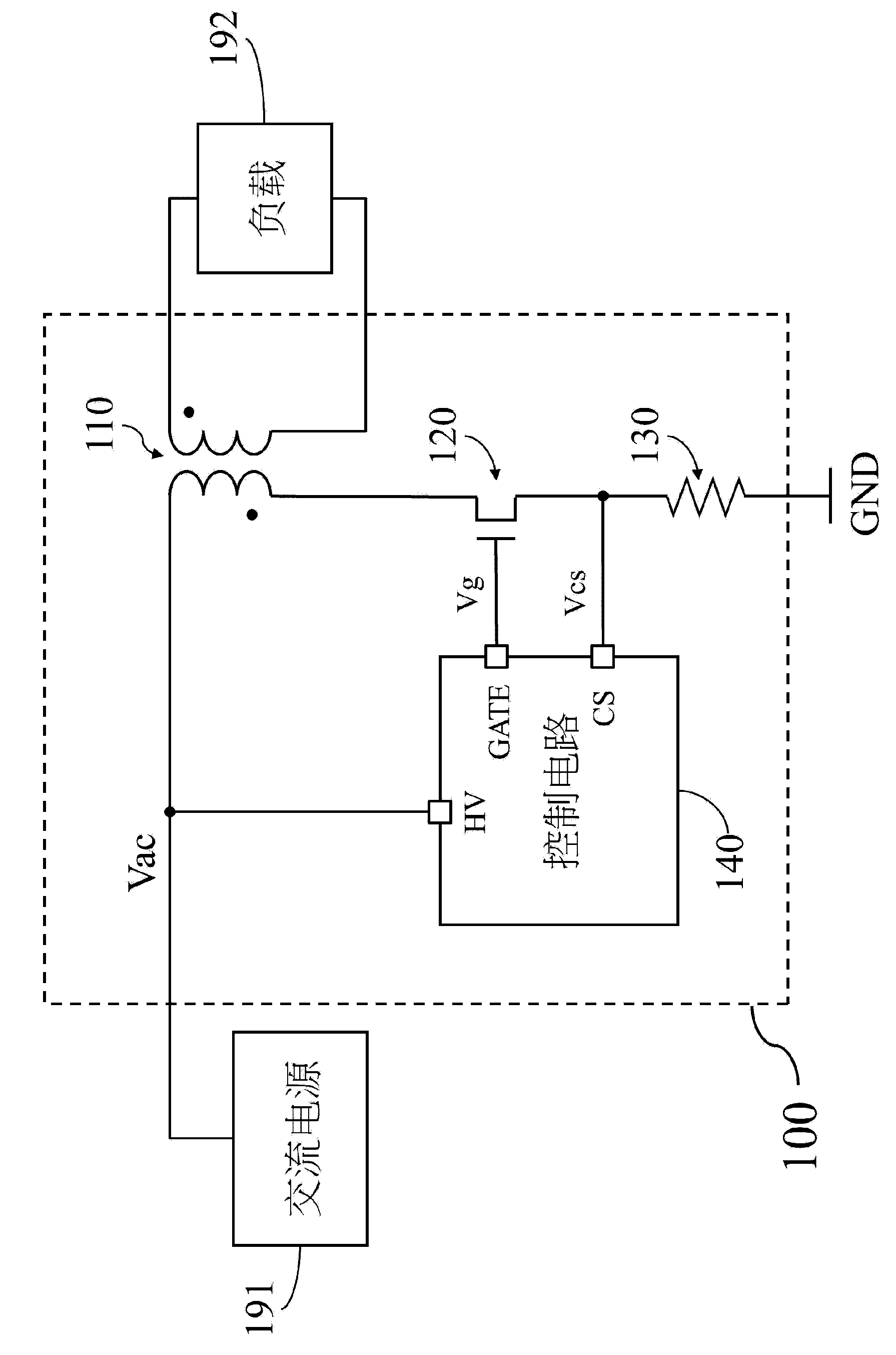

[0015] figure 1 It is a simplified functional block diagram of the AC-to-DC power converter 100 according to an embodiment of the present invention. The power conversion circuit 100 includes a transformer 110, a current switch 120, a resistor 130 and a control circuit 140, so that the input power signal according to the AC power source 191 Vac to supply power to the load 192 . In order to make the drawing concise and easy to explain, other components of the power conversion circuit 100 and related connection relationships are not shown in the figure 1 middle.

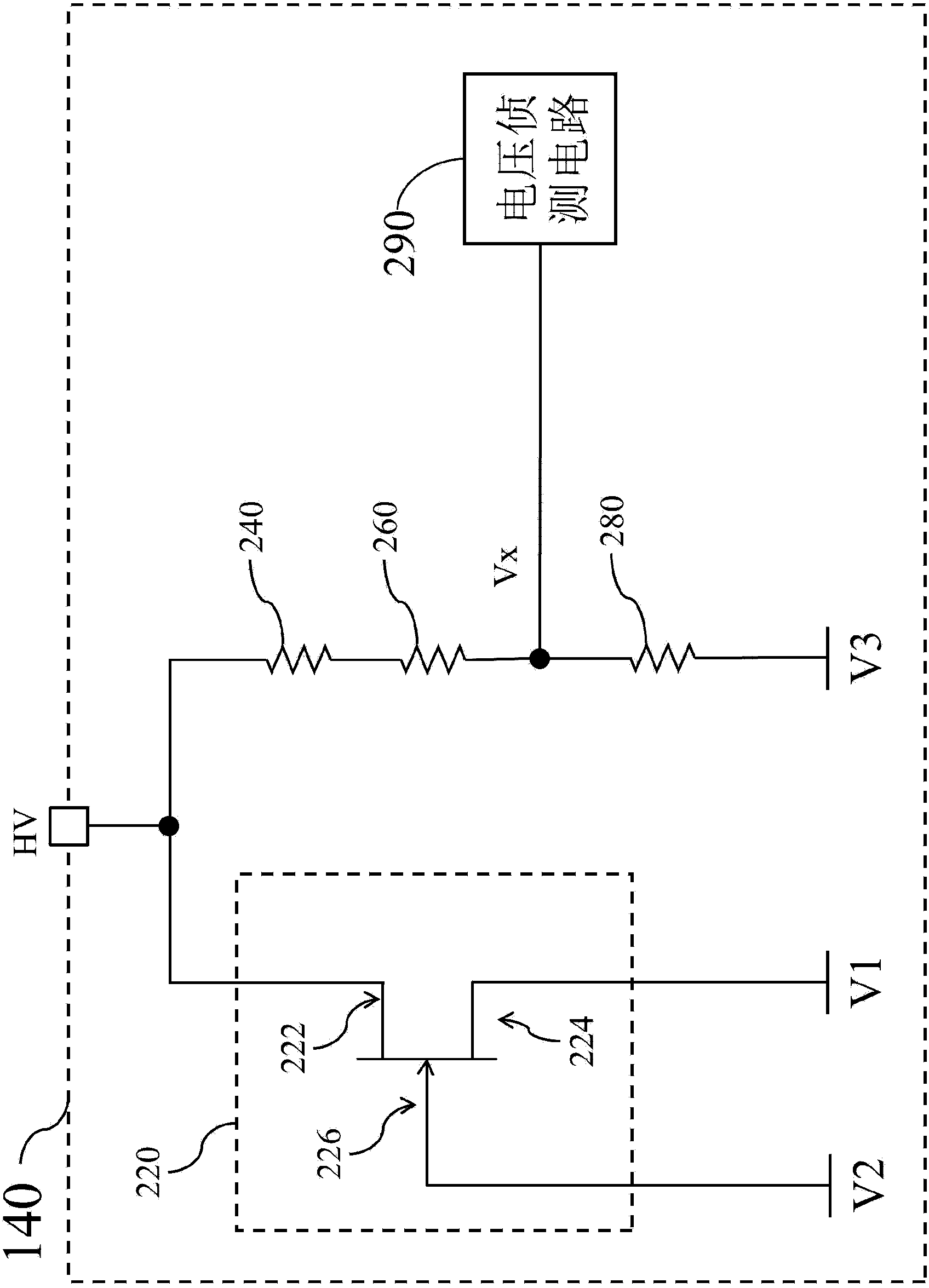

[0016] exist figure 1 In the embodiment, the transformer 110 is coupled between the AC power source 191 and the load 192, one end of the current switch 120 is coupled to the transformer 110, the other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com