Fixed power distribution cabinet convenient to mount and maintain

A power distribution cabinet and installation room technology, applied in the field of fixed power distribution cabinets, can solve the problems of cluttered lines in the cable room, inconvenient heat dissipation, etc., and achieve the effect of saving the time for finding lines, arranging the lines neatly, and improving the efficiency of heat removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

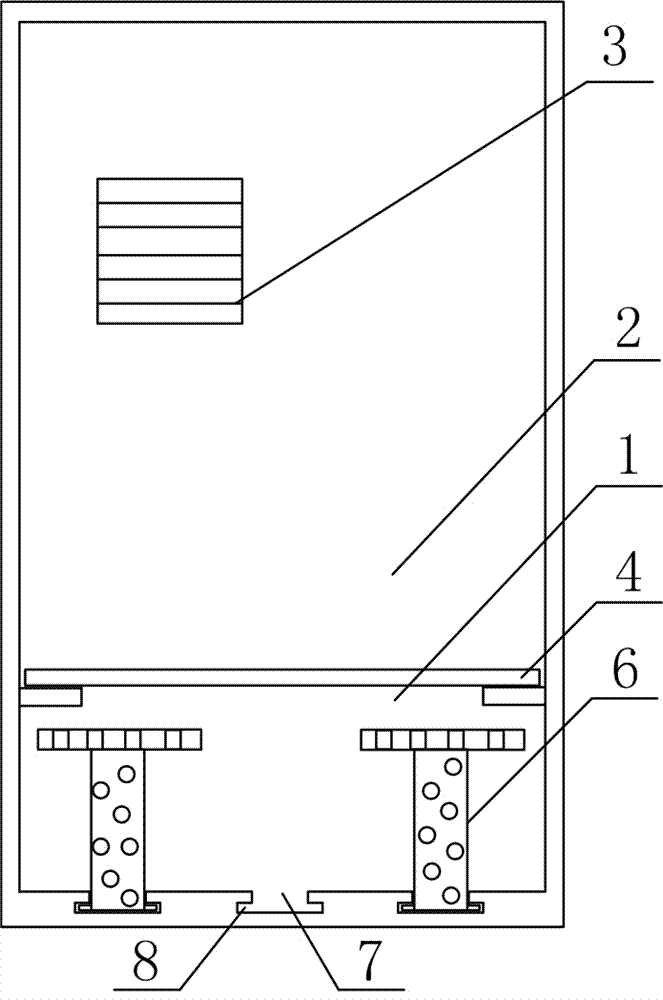

[0027] Fixed distribution cabinets for easy installation and maintenance, such as figure 1 As shown, it includes the cable room 1, the installation room 2, the vent 3, the detachable partition 4 and the hub 6. The specific arrangement of the above components and the connection relationship between them are as follows:

[0028] The cable room 1 is installed in the underground part, the installation room 2 is arranged above the cable room 1, and the cable room 1 and the installation room 2 are provided with air vents 3, such as figure 1 shown.

[0029] In order to facilitate maintenance and repair, a detachable partition 4 is arranged between the cable chamber 1 and the installation chamber 2, and the detachable partition 4 is provided with a line through hole 5, and the cable chamber 1 is also provided with a Hub 6, such as figure 1 shown.

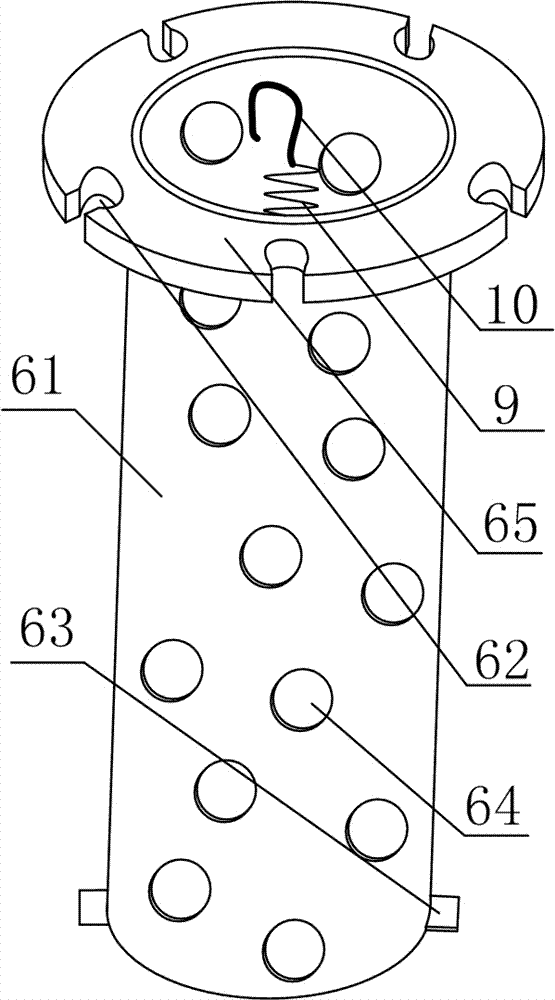

[0030] Such as image 3 As shown, the hub 6 is composed of a cylindrical barrel 61, a wire slot 62 arranged at the upper end of the...

Embodiment 2

[0034] The difference between this embodiment and Embodiment 1 is that the structure of the fixing member 63 is different. The specific structure of the fixing member 63 in this embodiment is set as follows:

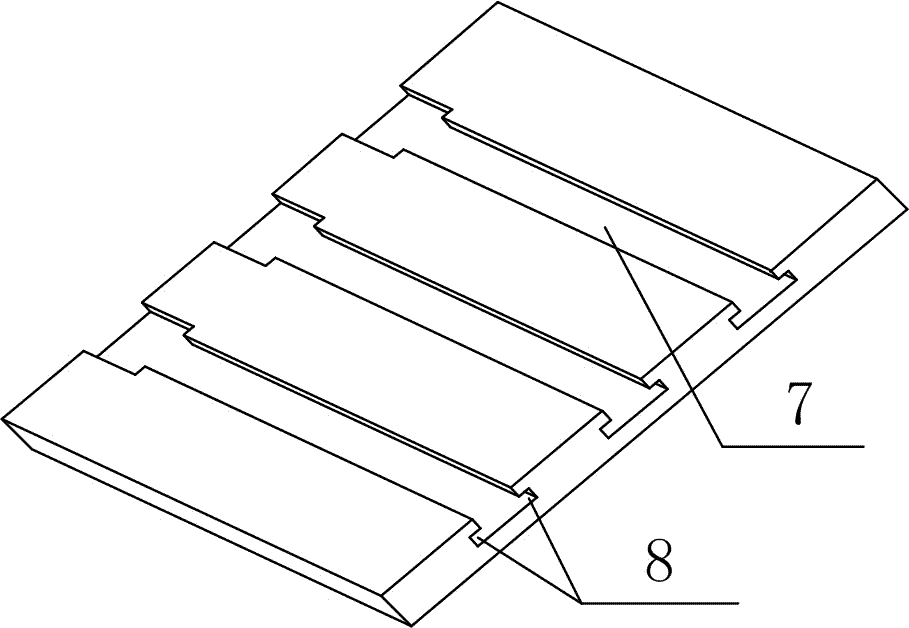

[0035] The fixing piece 63 is a fixing sheet arranged on opposite sides of the lower end of the cylinder body 61 , the bottom surface of the cable chamber 1 is provided with a groove body 7 having the same width as the diameter of the cylinder body 61 , and is arranged on both sides of the groove body 7 Card slot 8 matching the fixed piece, such as figure 2 shown.

[0036] Because the hub 6 is fixed on the groove body of the cable chamber 1 by the fixing piece thereon, it is all very convenient to take out and install. Therefore, before and after wiring, this setting method is very convenient for maintenance and repair of the line.

Embodiment 3

[0038] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that: the structure at the position of the clamping groove 62 is optimized, and the specific settings are as follows:

[0039] The upper end of the cylinder body 61 is provided with an annular connecting body 65, and the clamping grooves 62 are evenly distributed around the annular connecting body 65, as image 3 shown.

[0040] A hook 10 connected to the cylinder 61 through a spring 9 is also provided at the hollow position.

[0041] After all the redundant cables are wound on the cylinder body 61, one end extending to the installation chamber 2 is clipped into the cable clamping groove 62, and then the hook 10 is hooked to the cable, since the hook 10 is connected by the spring 9 To the hollow position of the cylinder body 61, the effect of the spring 9 can effectively tighten the cable between the wire clamping groove 62 and the hook 10, preventing the cable from coming out of the wire clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com