Cable positioning element and charging gun using same

A technology for positioning components and charging guns, applied in the direction of electrical components, battery circuit devices, current collectors, etc., can solve problems that affect the assembly of cables, and achieve the effect of avoiding axial offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The structure and effect of the present invention will be described in detail by citing the following embodiments in conjunction with the accompanying drawings.

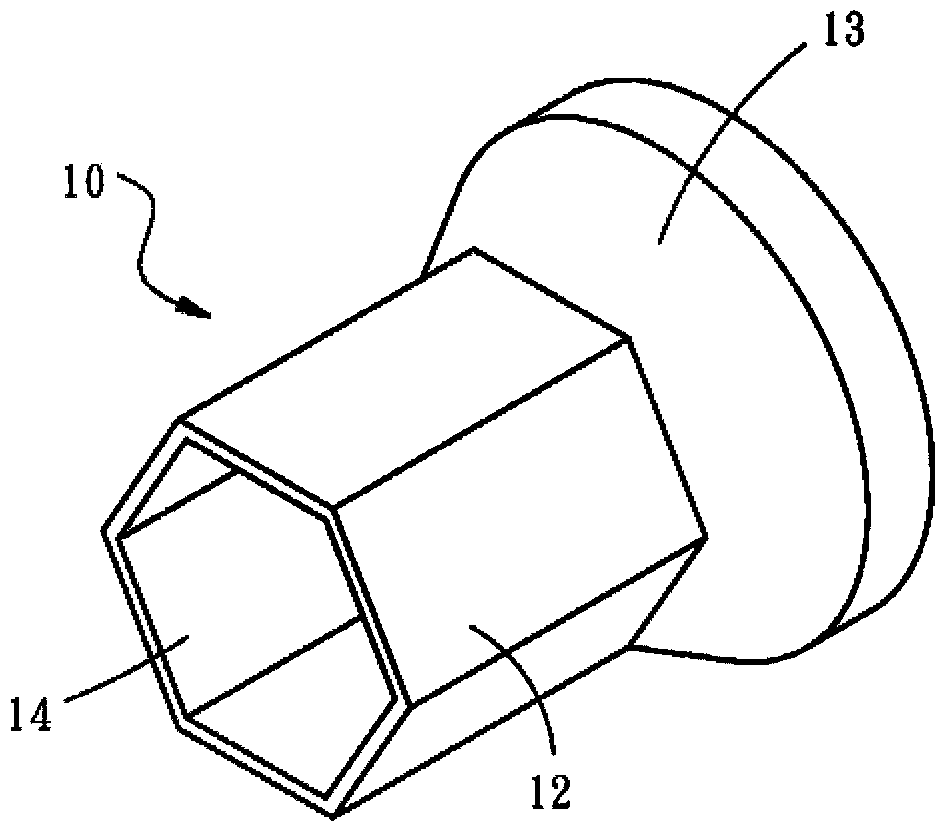

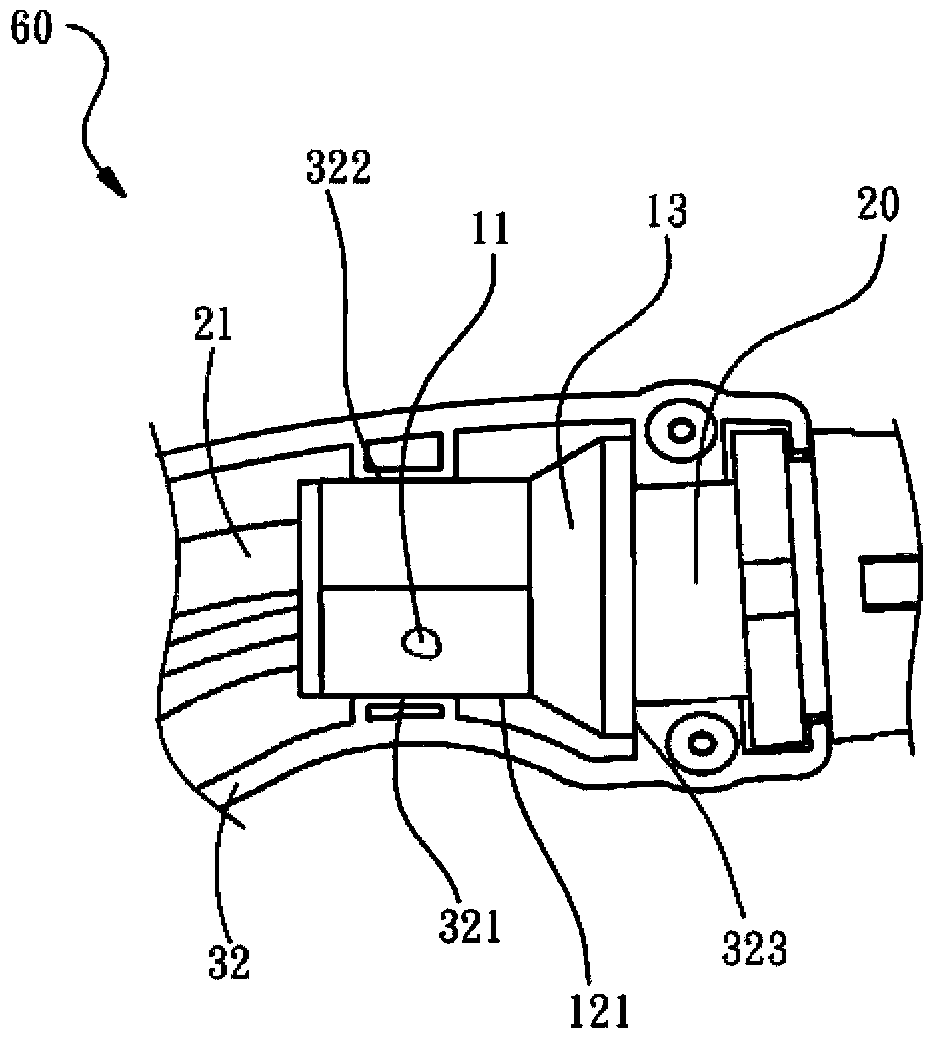

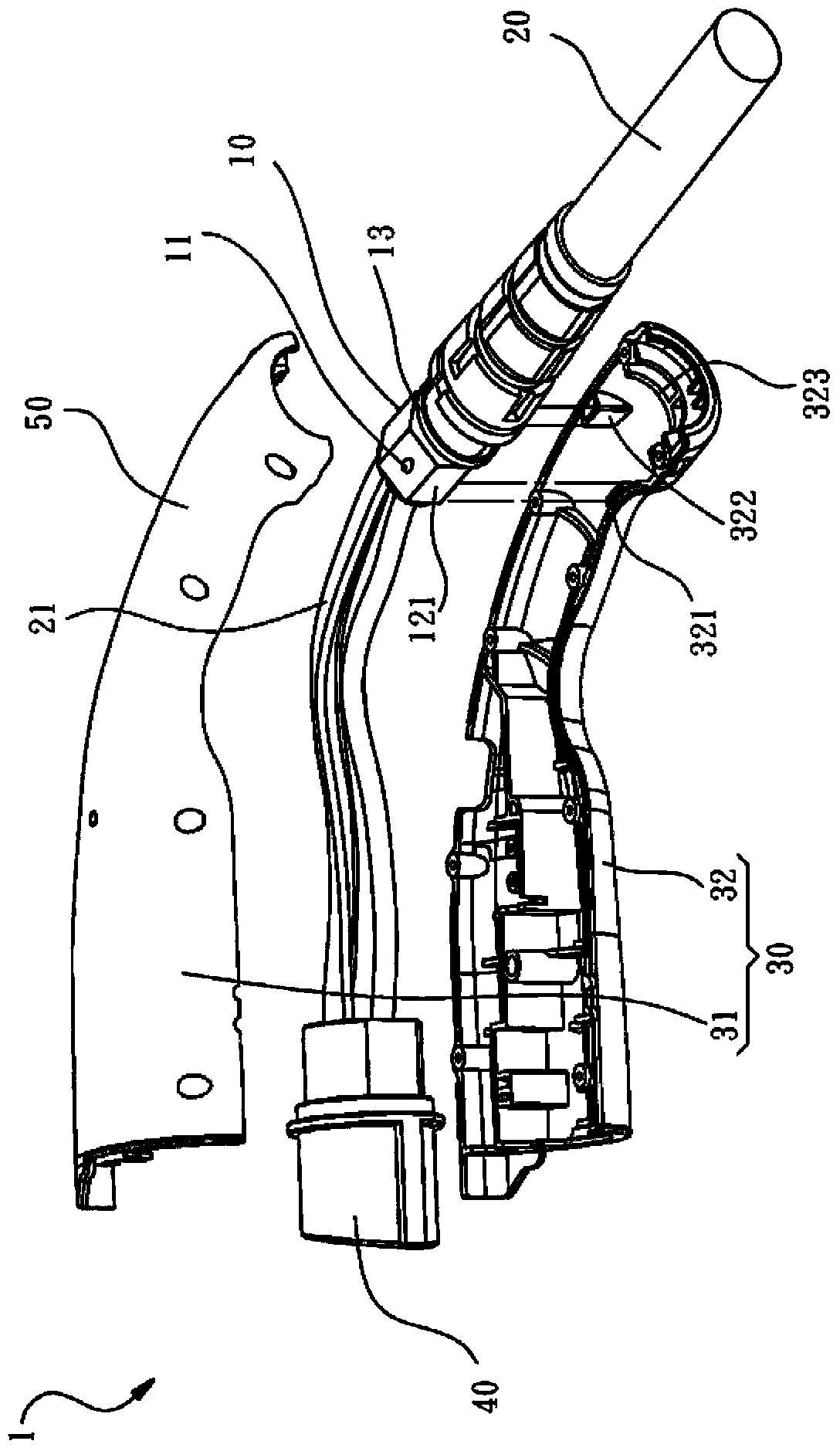

[0019] Such as Figure 1 to Figure 4 As shown, the preferred embodiment of the present invention provides a charging gun 1, which has a gun body 30, a grip portion 50 disposed on the gun body 30, and a mounting seat 60 integrally formed inside the grip portion 50. , a cable 20 passes through the grip portion 50, and a cable positioning element 10 is also provided inside the mounting base 60 for installing and positioning the cable 20. The cable positioning element 10 includes a cylinder 12 with a polygonal cross section, and the inner A hollow passage 14 is provided for the cable 20 to pass through. The cylinder 12 can be subjected to force to produce inelastic deformation to compress the cable 20 . The detailed component relationship description of this embodiment is as follows:

[0020] In this embodiment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com