Energy-saving motor capable of eliminating resistance of rotor tooth grooves

A technology of electric motor and rotor teeth, applied in the field of electric motor, can solve problems such as increasing the cost of electric motor, and achieve the effects of reducing three currents, reducing energy loss, and reducing reactive power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

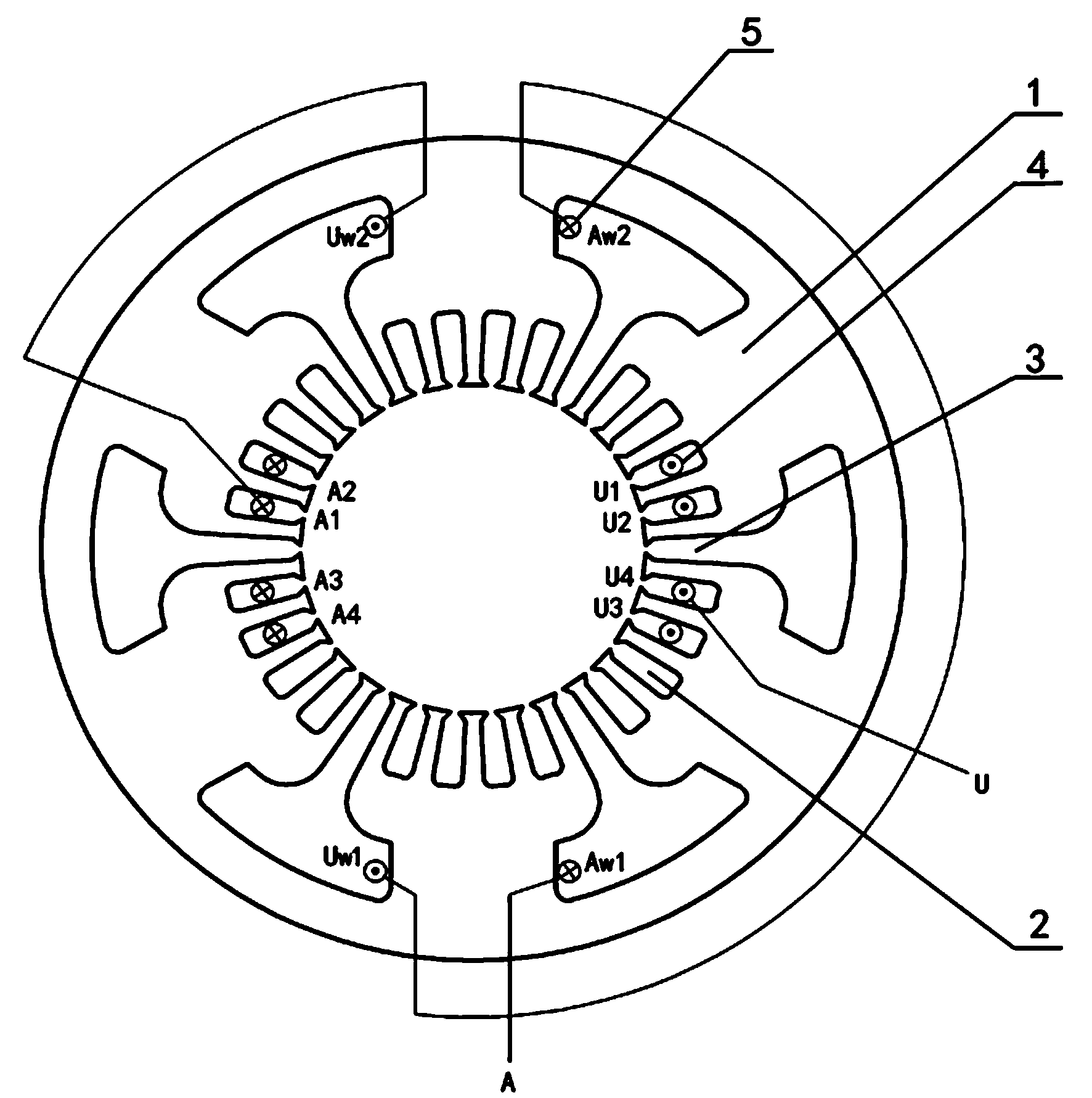

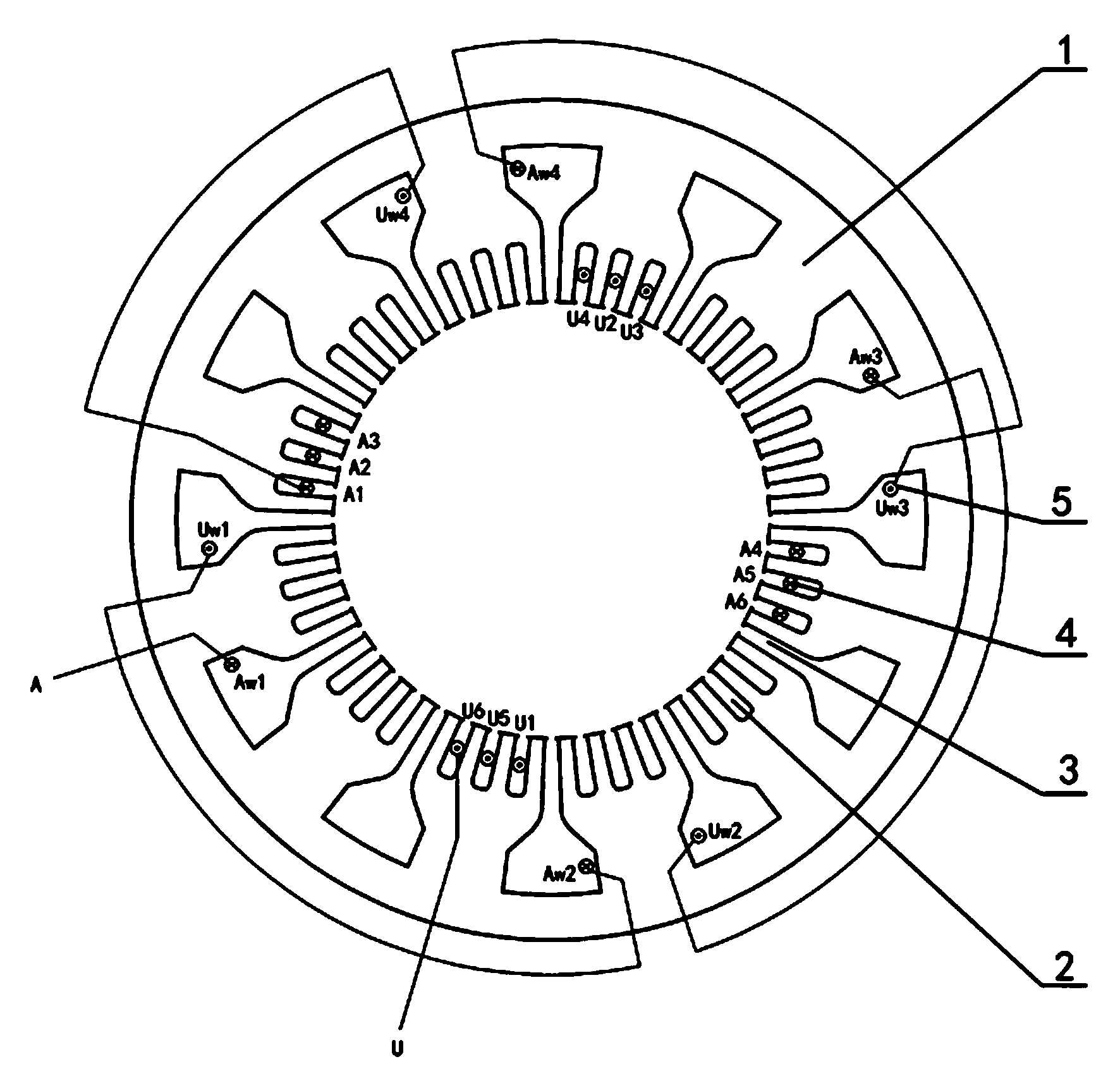

[0022] An energy-saving motor that eliminates the cogging force of the rotor. The stator core of the motor has a structure in which salient poles and cogging coexist, that is, there are both salient poles and cogging on the stator core, and the cogging is located inside the salient pole facing the rotor. On the end face, the salient poles are equipped with auxiliary windings, and the tooth slots are equipped with main windings.

[0023] figure 1 Shown is a single-phase winding connection method of a 2-pole 24-slot motor. Six stator salient poles 1 are distributed on the stator silicon steel sheet. The number of stator salient poles = 2 (poles) × 3 = 6 pieces. On the inner end surface of the pole 1 facing the rotor, no winding is arranged in the space of the salient pole gap 3 .

[0024] figure 1 A1-U1, A2-U2, A3-U3, and A4-U4 are the main winding 4 of the energy-saving motor that eliminates the rotor cogging force described in the present invention, and Aw1-Uw1 and Aw2-Uw2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com