A device and method for testing electric equipment

A kind of electric equipment, square wave technology, used in measuring devices, output power conversion devices, measuring electricity and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

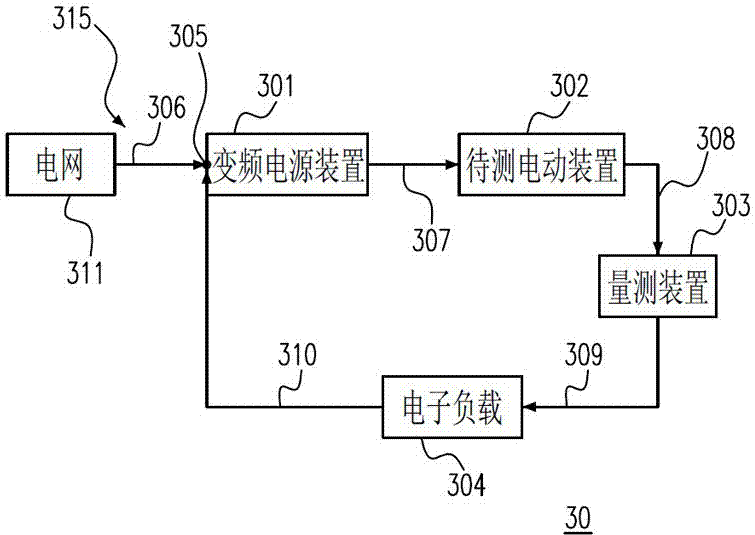

[0108] Embodiment one: see image 3 , which is a schematic diagram of a device 30 for testing electric equipment in Embodiment 1 of the present invention. The device 30 includes a variable frequency power supply device 301 , an electric device to be tested 302 , a measuring device 303 , and an electronic load 304 . see Figure 4 , which is a schematic diagram of the reference AC voltage / current and the feedback AC voltage / current. Please also see image 3 and Figure 4 The variable frequency power supply device 301 has an input terminal 305, the input terminal 305 receives a reference AC voltage 306, and the variable frequency power supply device 301 outputs a first AC voltage 307 with an adjustable parameter in response to the reference AC voltage 306. The electric device under test 302 generates a mechanical kinetic energy 308 in response to the first AC voltage 307 . The measuring device 303 converts the mechanical kinetic energy 308 into a second AC voltage 309 and me...

Embodiment 2

[0124] Example 2: Please refer to Figure 10 , which is a schematic diagram of a device 40 for testing electric equipment according to a second preferred embodiment of the present invention. The device 40 includes the variable frequency power supply device 301 , the electrical equipment under test 302 , the measuring device 303 , and a rectifying unit 3020 . The variable frequency power supply device 301 includes a rectification unit 3011 and an inverter 3013 . The variable frequency power supply device 301 has an input terminal 305 , the input terminal 305 receives a power 401 , and the rectification unit 3011 responds to the reference AC voltage 306 of the power 401 to output a DC voltage VDC1 . The converter 3013 includes a converter unit 3014, and outputs a first AC voltage 307 with an adjustable parameter in response to the DC voltage VDC1. The electric device under test 302 generates mechanical kinetic energy 308 in response to the first AC voltage 307 . The measuring...

Embodiment 3

[0127] Example 3: Please refer to Figure 11 , which is a schematic diagram of a power saving device 50 for testing an energy conversion device in Embodiment 3 of the present invention. The power saving device 50 includes a variable frequency power supply device 501 , the energy conversion device 502 , and an electronic load 503 . The variable frequency power supply device 501 outputs a second power 505 in response to a first power 504 . The energy conversion device 502 generates kinetic energy in response to the second electric power 505 , converts the kinetic energy into a third electric power 506 , and measures the kinetic energy by the third electric power 506 . The electronic load 503 generates a fourth power 507 in response to the third power 506 , wherein the fourth power 507 is mixed with the first power 504 to recover the first power 504 .

[0128] In the third embodiment of the present invention, the first electric power 504 is sent from the grid 508, and the energ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com