Electric drive pump assembly

An electric drive and assembly technology, applied in engine components, pump/compressor arrangement, diaphragm valves, etc., can solve problems such as conflict of purpose and undesired cost, and achieve the effect of simplified structure and less pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

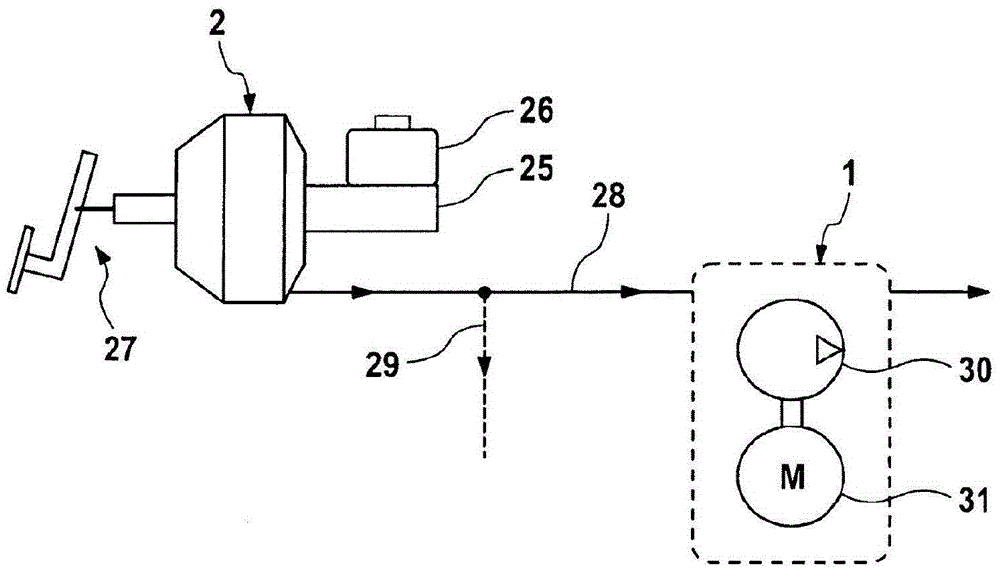

[0042] figure 1

[0043] Pump unit 1 , which essentially includes pump 30 and electric pump drive unit 31 , is connected to pneumatic brake booster 2 via a low-pressure line 28 . In this case, a low-pressure line 28 pneumatically connects a not-shown low-pressure chamber of the brake booster 2 and a not-shown inlet channel 8 of the pump unit 1 to one another, whereby air can be drawn from the low-pressure chamber. Exhaust through pump assembly 1. In addition, the brake booster 2 can be connected to a further low-pressure line 29 which is connected, for example pneumatically, to the suction line of the internal combustion engine and which also serves to remove air from the brake booster 2 . . In the sketch shown, the main brake cylinder 25 is arranged on the brake booster 2, the pressure medium container 26 is hydraulically connected to the main brake cylinder 25, it is not important here that the pressure medium container 26 is as shown directly or via a remote line to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com