Tool group of tillage machine

A technology of cultivating machines and knives, which is applied in the fields of tillage machines, agricultural machinery and tools, etc. It can solve the problems of intermittent large impact force, increased unit vibration, incomplete stubble removal, etc., and achieve the goal of overcoming severe impact and beating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

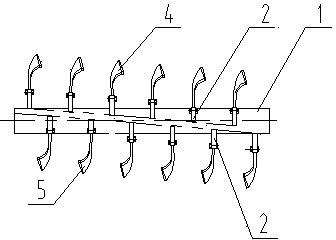

[0015] The cultivator knife set shown in the accompanying drawings includes a frame cutter shaft 1, a knife seat 2, a left curved blade 5, and a right curved blade 4; the knife seat 2 is fixedly connected to the knife shaft 1, and the left curved blade 5 and the right curved blade 4 is fixedly connected in the knife seat 2; the knife seat 2 for fixing the left curved blade 5 and the knife seat 2 for fixing the right curved blade 4 are respectively arranged along the helical line of the outer wall of the knife shaft 1 in the same direction of rotation.

[0016] In this embodiment, the pitch of the two helical lines is the same, and the helix angle of the two helical lines is 5°. The knife seat 2 for fixing the left curved blade 5 and the knife seat 2 for fixing the right curved blade 4 are respectively along the spiral Arranged at eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com