Control system and control method thereof coaxial cable production line

A coaxial cable and control system technology, applied in the manufacture of coaxial cables, comprehensive factory control, electrical program control, etc., can solve the problem of low product qualification rate, inability to detect the tightness and pitch of the braid layer in real time, and inability Detect problems such as the aluminum foil layer in a short time, to achieve the effect of improving the level of automation and improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

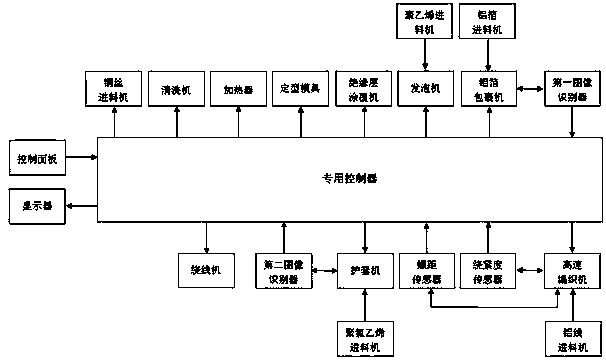

[0019] Such as figure 1 As shown, a control system for a coaxial cable production line includes a control panel, a display, a dedicated controller, a copper wire feeder, a cleaning machine, a heater, a shaping die, an insulating layer coating machine, a foaming machine, a polymer Vinyl feeding machine, aluminum foil wrapping machine, aluminum foil feeding machine, first image recognizer, high-speed braiding machine, aluminum wire feeding machine, winding tightness sensor, pitch sensor, sheathing machine, PVC feeding machine, first 2. Image recognizer, winding machine; special controllers are respectively connected with control panel, display, copper wire feeding machine, cleaning machine, heater, shaping mold, insulating layer coating machine, foaming machine, aluminum foil wrapping machine, the first Image recognizer, high-speed braiding machine, winding tightness sensor, pitch sensor, sheathing machine, second image recognizer, winding machine are connected; foaming machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com