Urea scr catalyst based on ion exchange molecular sieve

A technology of SCR catalyst and ion exchange, applied in molecular sieve catalysts, physical/chemical process catalysts, separation methods, etc., can solve problems such as escape, incomplete pyrolysis and hydrolysis of urea, and reduced activity, so as to avoid uneven coating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

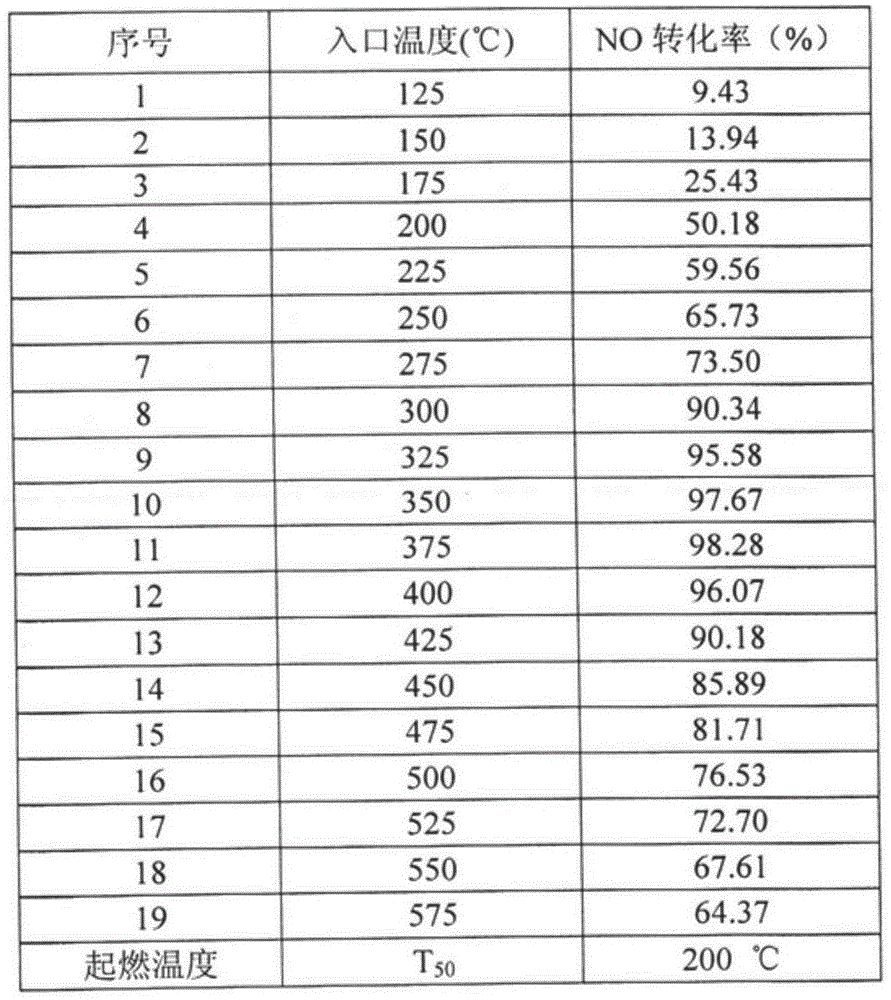

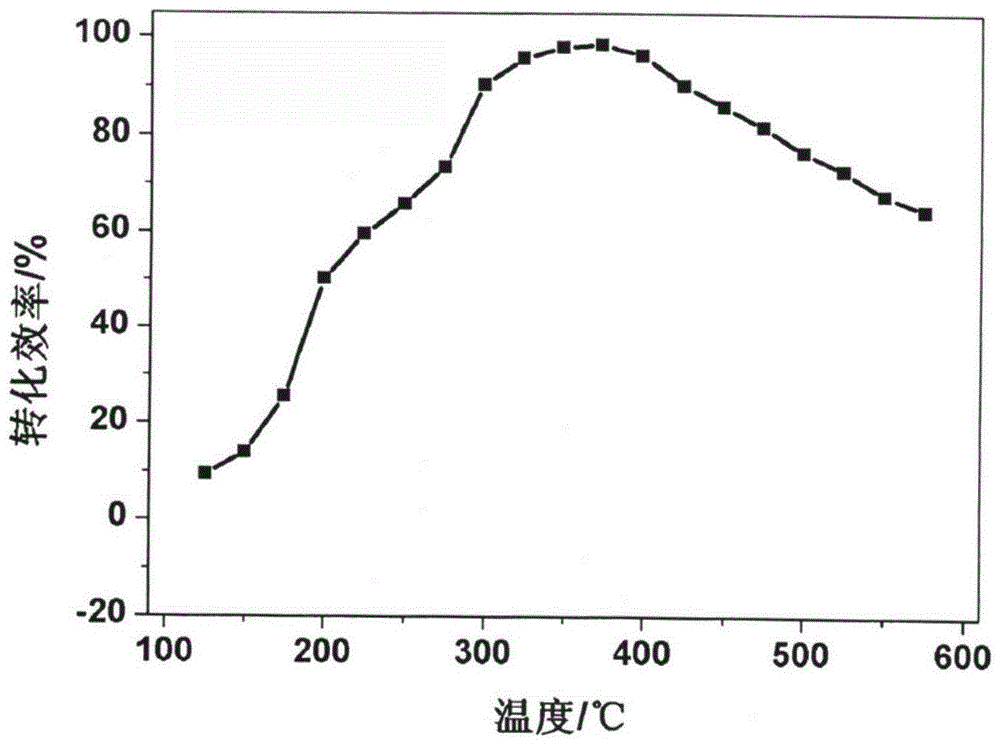

Embodiment 1

[0036] This embodiment provides a urea SCR catalyst based on ion exchange molecular sieve, and its preparation process includes:

[0037] Step 1: Take 1000g of HZSM-5 molecular sieve particles and mix them with water to make a molecular sieve slurry. The water content of the molecular sieve slurry is suitable for mixing with the copper ion solution. The active agent copper nitrate solution containing copper ions is added to the molecular sieve slurry and mixed to obtain a mixed slurry. The copper nitrate solution is made by adding 113.3 g of copper nitrate trihydrate into water so that the content of the active component copper ions in the mixed slurry is 3%.

[0038] Step 2: Adjust the pH value of the mixed slurry to 8.9, keep the mixed slurry weakly alkaline, and stir for 20 hours to obtain an active slurry that has completed ion exchange.

[0039] Step 3: After the active slurry is filtered, it is dispersed into small pieces with a blue color; the small pieces of filter cake are ...

Embodiment 2

[0043] This embodiment provides a urea SCR catalyst based on ion exchange molecular sieve, and its preparation process includes:

[0044] Step 1: Take 1000g of HZSM-5 molecular sieve particles and mix them with water to make a molecular sieve slurry. The water content of the molecular sieve slurry is suitable for mixing with the copper ion solution. The active agent copper nitrate solution containing copper ions is added to the molecular sieve slurry and mixed to obtain a mixed slurry. The copper nitrate solution is made by adding 302.4 g of copper nitrate trihydrate into water so that the content of the active component copper ions in the mixed slurry is 8%.

[0045] Step 2: Adjust the pH value of the mixed slurry to 9.0, keep the mixed slurry weakly alkaline, and stir for 25 hours to obtain an active slurry that has completed ion exchange.

[0046] Step 3: After the active slurry is filtered, it is dispersed into small pieces with a blue color; the small pieces of filter cake are ...

Embodiment 3

[0050] This embodiment provides a urea SCR catalyst based on ion exchange molecular sieve, and its preparation process includes:

[0051] Step 1: Take 1000g of HZSM-5 molecular sieve particles and mix them with water to make a molecular sieve slurry. The water content of the molecular sieve slurry is suitable for mixing with the copper ion solution. The active agent copper nitrate solution containing copper ions is added to the molecular sieve slurry and mixed to obtain a mixed slurry. The copper nitrate solution is made by adding 188.9 g of copper nitrate trihydrate into water so that the content of the active component copper ion in the mixed slurry is 5%.

[0052] Step 2: Adjust the pH of the mixed slurry to 9.1, keep the mixed slurry weakly alkaline, and stir for 20 hours; to obtain an active slurry that has completed ion exchange.

[0053] Step 3: After the active slurry is filtered, it is dispersed into small pieces with a blue color; the small pieces of filter cake are dried ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com