Oven for baking battery substrate

A technology for drying batteries and substrates, which is applied to the device for coating liquid on the surface, pre-treating the surface, coating, etc., which can solve the problems of complicated procedures, low drying efficiency, increased workload, etc., and shorten the baking time , Simplify the process and improve the baking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

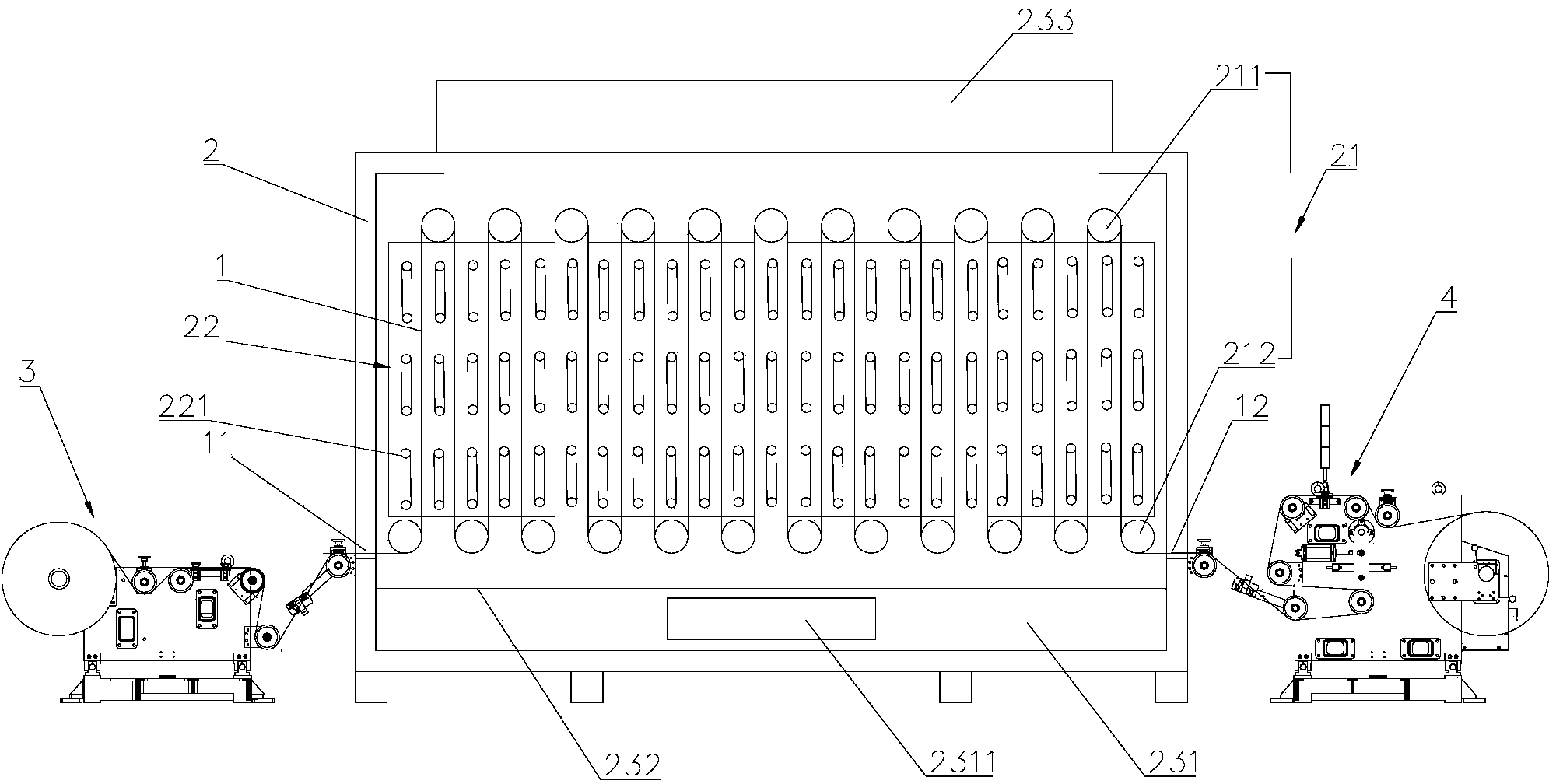

[0010] The most critical idea of the present invention is to provide an oven for drying battery substrates. The oven box is provided with upper and lower rows of rollers distributed alternately. The vertical direction between the upper and lower rows of rollers is There is a channel for the substrate, and the heating pipes are distributed alternately with the channel for the substrate. The substrate can be heated while moving in the heating channel and heated evenly; there is a blower mechanism in the box to take away the water vapor evaporated when the substrate is heated in time. And organic solvents, without vacuuming and injecting inert gas; the unwinding mechanism, the box and the winding mechanism are connected in sequence, unwinding, drying, and winding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com