Magnetic punch

A stamping machine and magnetic technology, applied in the field of automation equipment, can solve the problems of high purchase and use costs, large power consumption, and large vibrations, and achieve the effects of low equipment production costs, low use costs, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment the present invention is further described:

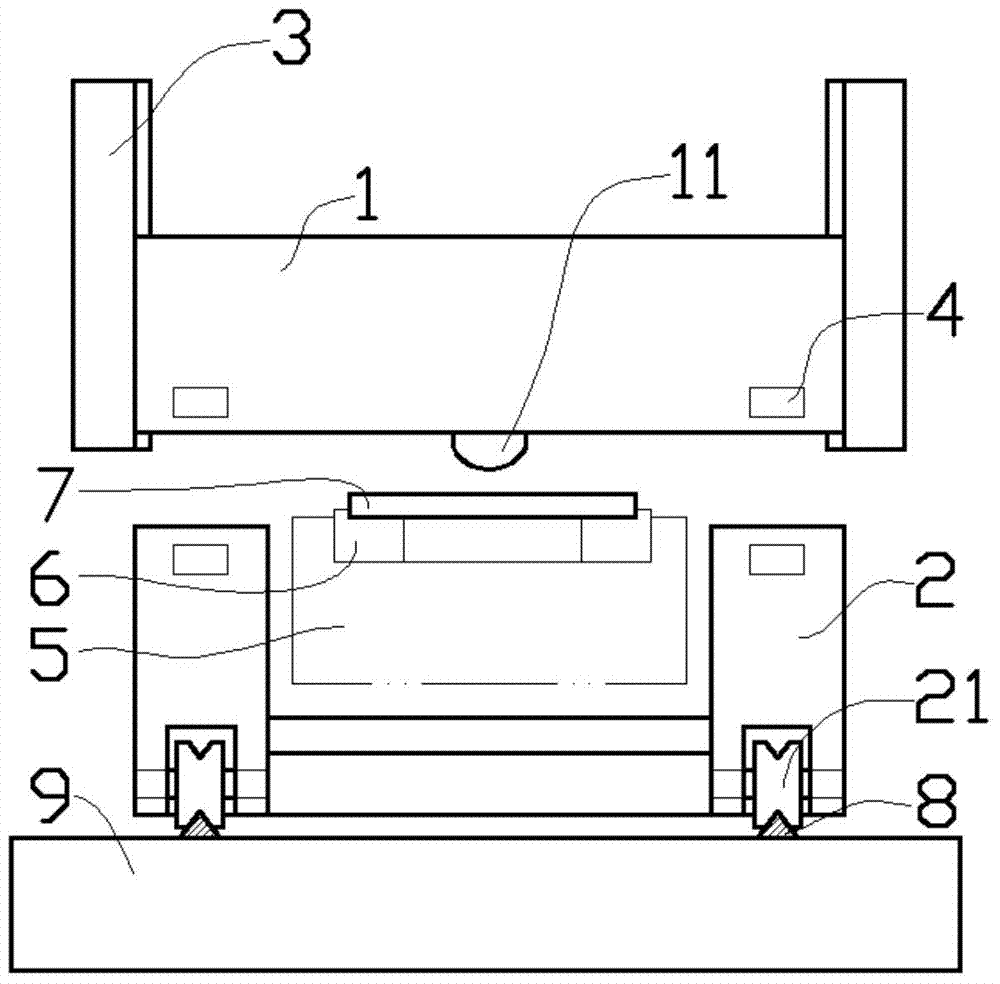

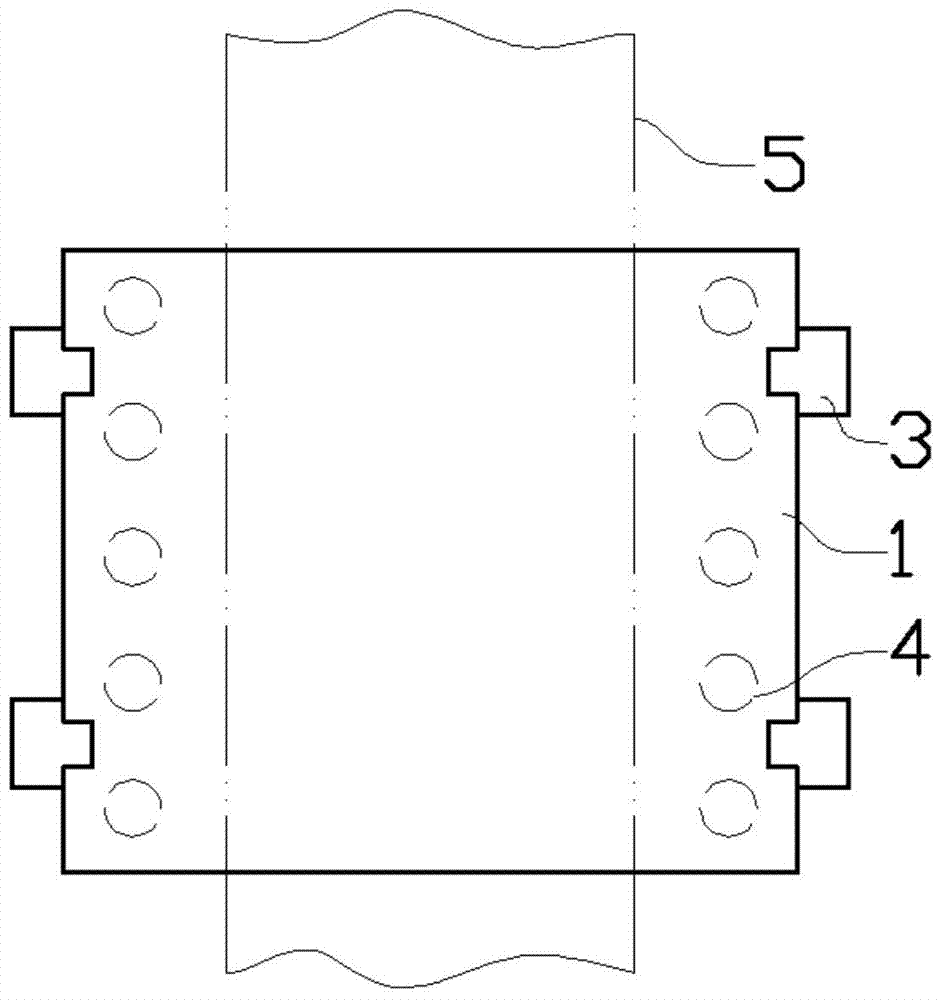

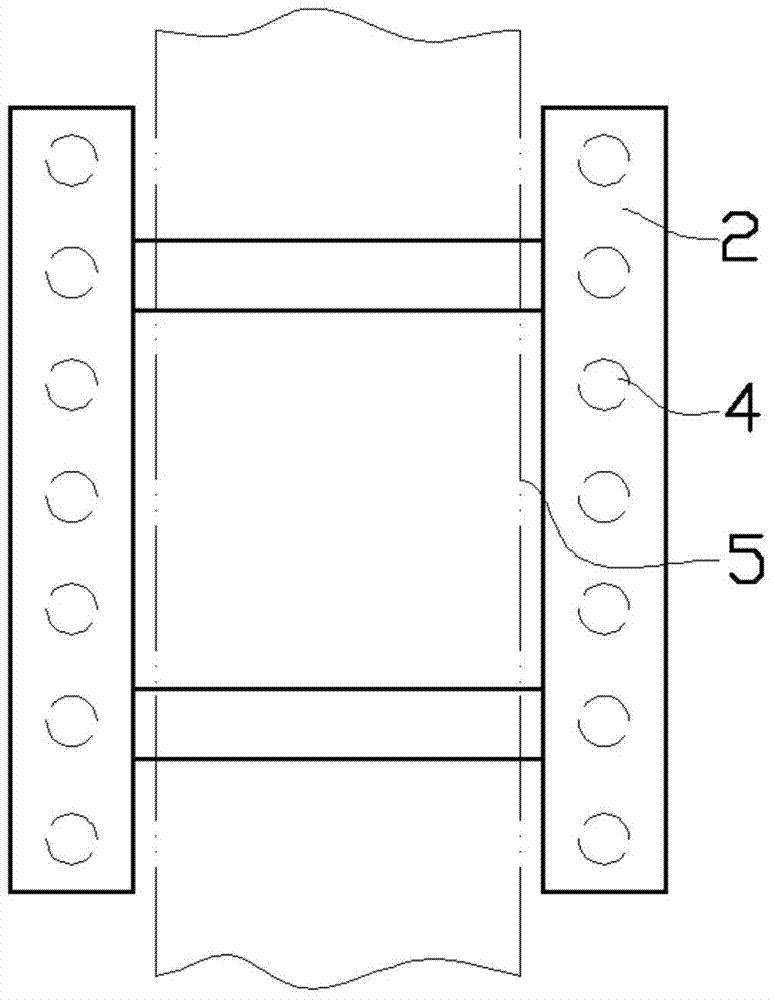

[0014] Such as figure 1 , figure 2 with image 3 As shown in the embodiment, the magnetic stamping machine includes a stamping block 1 and a magnetic trolley 2; the stamping block 1 is in a rectangular shape, and the two sides of the stamping block 1 are limited by vertical limit columns 3, and the The cross-section of the spacer post 3 can be designed as a trapezoid, and two of them are respectively assembled on each side of the both sides of the stamping block 1, so that the stamping block 1 can only slide vertically up and down. The two sides of the lower part of the stamping block 1 are fixed with small magnetic blocks 4 with vertical magnetic force lines, and the direction of the magnetic force lines of adjacent small magnetic blocks 4 on each side of the stamping block 1 is vertically opposite. The small magnetic blocks 4 on the side are symmetrically arranged, and the magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com