Dynamic weighing and feeding device for spherical oxidant and control method

A feeding device and dynamic weighing technology, applied in loading/unloading, transportation and packaging, conveying bulk materials, etc., can solve problems such as potential safety hazards, achieve the effects of protecting safety, improving work efficiency, and reducing operating labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

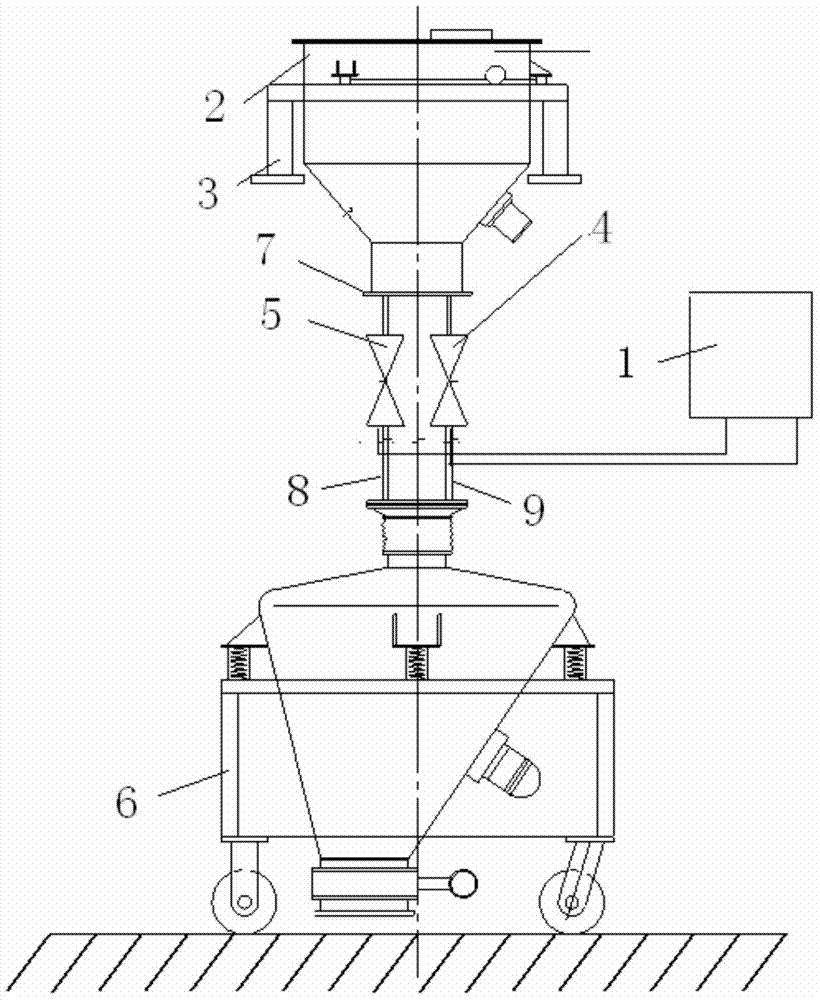

[0021] This embodiment is a dynamic weighing and feeding device for a spherical oxidant, which includes a weighing hopper 2, a mass scale 3, a feeding cart 6 and a feeding valve. The spherical oxidizer dynamic weighing and feeding device is obtained after improving the prior art. Wherein, the discharge port of the weighing hopper 2 is communicated with the feed port of the transport truck 6 through the discharge pipeline, and an adapter plate 7 is fixed on the discharge port of the weighing hopper 2, and there are two A discharge pipe interface is respectively connected with one end of the first discharge pipe 8 and the second discharge pipe 9 located below the adapter plate. The other ends of the first discharge pipeline 8 and the second discharge pipeline 9 are respectively connected to the feed port of the transport truck 6 . The pipe diameter of the first discharge pipeline: the pipe diameter of the second discharge pipeline=3:1.

[0022] The feed valve includes a first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com