Top-distribution energy-saving high-concentration anaerobic fermentor

An anaerobic fermentation, high-concentration technology, applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical instrument, etc., can solve problems such as deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

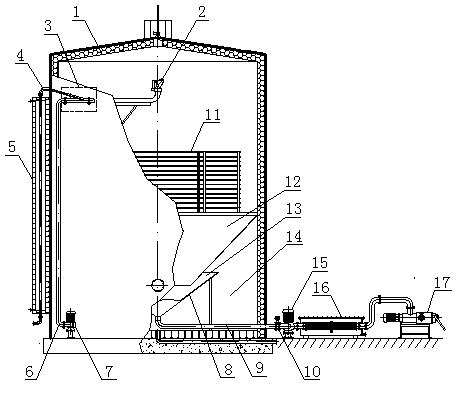

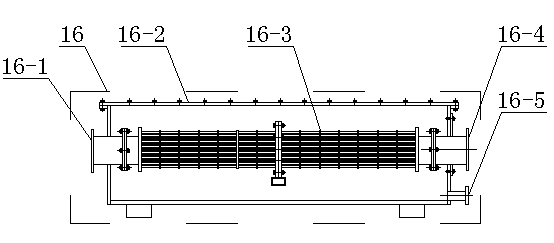

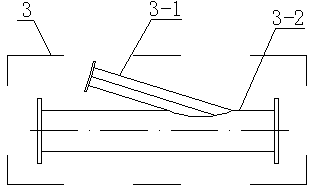

[0010] See attached figure 1 , 2 , 3, 4, a kind of energy-saving high-concentration anaerobic fermenter with upper cloth disclosed by the present invention is characterized in that: a cloth nozzle 2 is erected on the upper part of the vertical bucket type anaerobic fermenter body 1, and a reflux pump 7 and The reflux pipe 6 draws out the biogas slurry from the eluate flow space 14 at the bottom of the fermenter body 1, so that it is transported to the distribution nozzle 2 through the solid-liquid mixing tee 3, and the solid material is communicated with a screw extruder or a plunger pump. The pre-heater 5 and the communication pipe 4 are mixed with the return biogas slurry by the solid-liquid mixing tee 3 installed on the return pipe 6, and then sent to the cloth nozzle 2 to complete the upper cloth, and the middle and upper layers of the fermenter body 1. One-stage or single-stage heater 11, under the heater 11, a trapezoidal cone bucket 12 and a jacket umbrella-shaped con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com