Ocean engineering foundation adopting pile-barrel foundation structure

A technology of marine engineering and bucket foundation, which is applied in the field of marine engineering foundation and its construction, can solve the problems of many influencing factors, and achieve the effect of good vertical bearing capacity and good resistance level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Sink the bucket first and then sink the pile

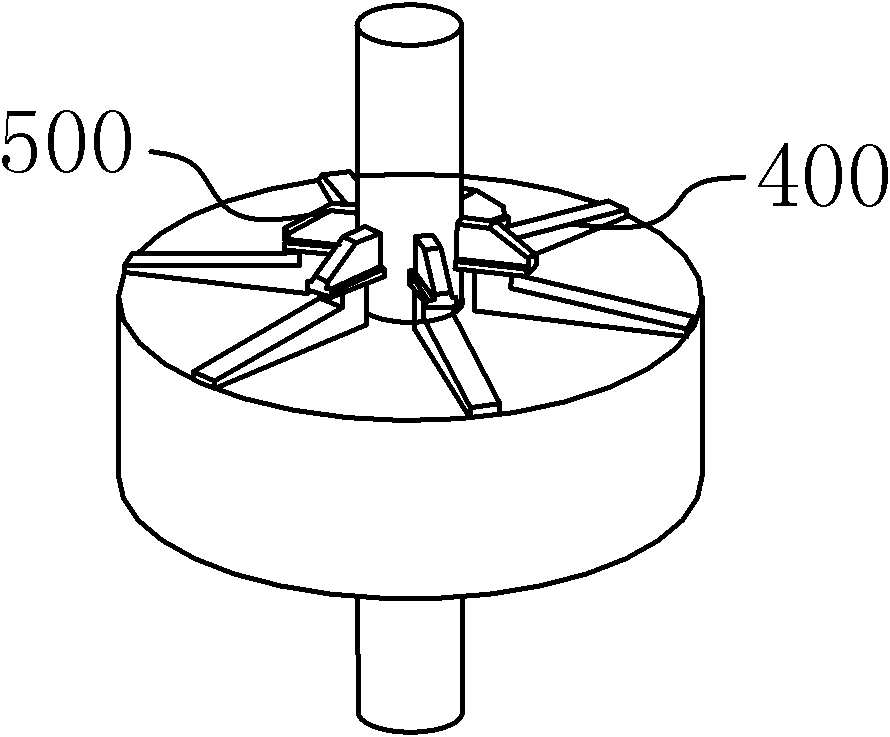

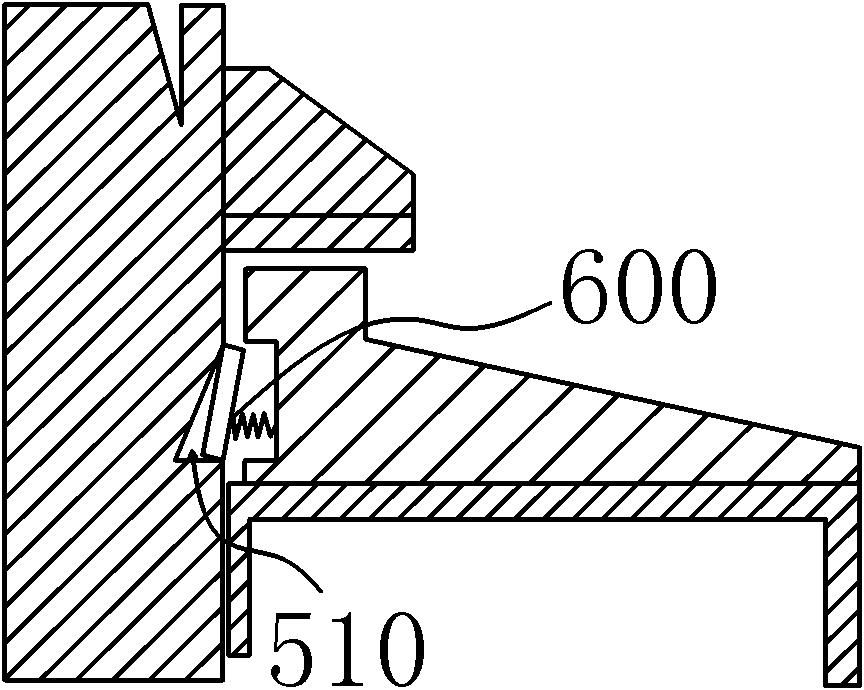

[0025] Such as figure 1 , as shown in 2, 3, and 4, a marine engineering foundation adopting a pile-barrel foundation structure, including a pile body and a barrel body, six symmetrical ribs 400 are arranged on the top of the barrel body, and the symmetrical ribs 400 play a role in fixing The function of stabilizing the barrel body, strengthening the structure of the barrel body, and preventing the horizontal deformation of the top surface of the barrel. The shape is composed of a triangle and a rectangle, and the rectangular top of the rib plate is slightly higher to support the pile body. A spring cube is arranged on the facade of the rib near the mouth end of the bucket.

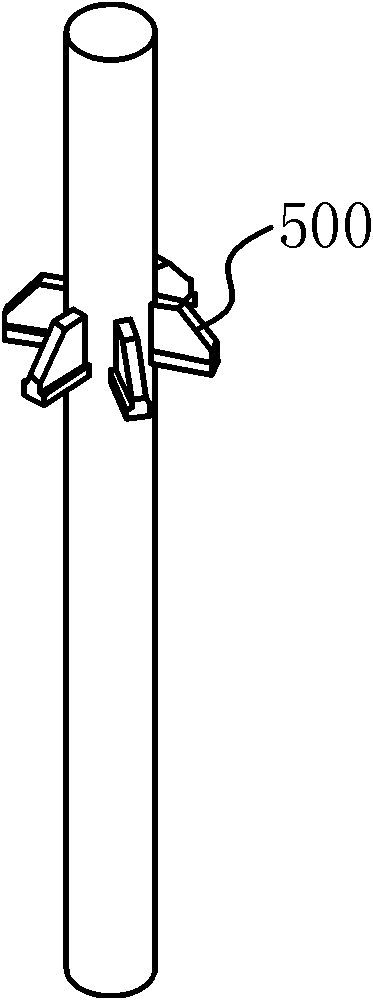

[0026] Six symmetrical trapezoidal pile wings are correspondingly arranged at about 1 / 3 of the top of the pile body. Below the pile wing 500, six symmetrical downward opening grooves 510 are arranged on the pile body corresponding to the f...

Embodiment 2

[0029] Embodiment 2: the method of sinking the pile first and then sinking the bucket

[0030] Such as Figure 5 , as shown in 6, a marine engineering foundation using a pile-bucket foundation structure, including a pile body and a barrel body, the top 1 / 3 of the pile body 100 is provided with a disc support plate 110 of the same material, and its radius is larger than that of the barrel mouth 210 radius, to play the effect of supporting barrel body 200. Six symmetrical ribs 220 are arranged on the top of the bucket, and the symmetrical ribs 220 play a role in fixing the stability of the bucket body 200, strengthening the structure of the bucket body, and preventing the horizontal deformation of the top surface of the bucket. A gap is reserved under the rib plate 220, and a felt rubber ring is fixed near the bung mouth 210, with an opening at its center, and the opening diameter is slightly smaller than the diameter of the pile body 100 to play a sealing role.

[0031] When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com